Introduction

In today's demanding industrial environments, finding reliable insulation solutions that effectively manage both thermal challenges and acoustic disturbances has become increasingly critical. The Adhesive Flannel Insulation Tape-High Heat Resistant Flame Retardant Masking Tape for Abnormal Noise Reduction Shock Damping represents a breakthrough in multifunctional protective materials. This advanced flannel-based tape combines exceptional thermal resistance with superior sound dampening properties, making it an indispensable tool for manufacturers, automotive specialists, and industrial maintenance professionals worldwide. Its unique construction addresses multiple performance requirements simultaneously, offering both heat protection and noise control in a single, easy-to-apply solution.

Product Overview

This specialized flannel insulation tape delivers comprehensive protection through its carefully engineered multi-layer construction. The flannel substrate provides excellent conformability and surface adhesion, while the heat-resistant adhesive system ensures reliable bonding even under extreme temperature conditions. The flame retardant properties meet stringent safety standards, making this tape suitable for applications where fire resistance is paramount. Unlike conventional masking tapes, this product excels in environments requiring both thermal insulation and vibration dampening capabilities.

The tape's distinctive flannel surface texture enhances its acoustic absorption characteristics, effectively reducing unwanted noise transmission across various frequencies. Its robust adhesive backing maintains consistent performance across temperature fluctuations, ensuring long-term reliability in challenging operational conditions. The combination of thermal resistance and sound attenuation makes this product particularly valuable for complex industrial applications where multiple environmental factors must be addressed simultaneously.

Features & Benefits

Superior Heat Resistance and Thermal Protection

The advanced polymer composition of this Adhesive Flannel Insulation Tape-High Heat Resistant Flame Retardant Masking Tape for Abnormal Noise Reduction Shock Damping ensures exceptional performance under elevated temperatures. The heat-resistant formulation maintains its protective properties and adhesive strength even when exposed to significant thermal stress. This thermal stability prevents degradation, cracking, or adhesive failure that commonly occurs with standard tapes in high-temperature environments. The flannel substrate acts as an effective thermal barrier, reducing heat transfer and protecting sensitive components from temperature-related damage.

Advanced Flame Retardant Properties

Safety remains paramount in industrial applications, and this specialized tape incorporates flame retardant compounds that significantly reduce fire propagation risk. The flame retardant characteristics comply with international safety standards, providing peace of mind in applications where ignition sources may be present. This enhanced safety profile makes the tape suitable for electrical applications, automotive systems, and manufacturing processes where fire prevention is critical. The self-extinguishing properties help contain potential fire incidents, protecting both equipment and personnel.

Exceptional Noise Reduction and Vibration Dampening

The flannel surface texture creates an effective acoustic barrier that absorbs sound waves and reduces noise transmission. This noise reduction capability addresses abnormal sounds generated by mechanical vibrations, electrical interference, and operational resonances. The shock dampening properties help isolate sensitive components from vibration-induced damage, extending equipment lifespan and improving operational reliability. The combination of acoustic absorption and vibration isolation makes this tape invaluable for reducing workplace noise levels and enhancing operational comfort.

Applications & Use Cases

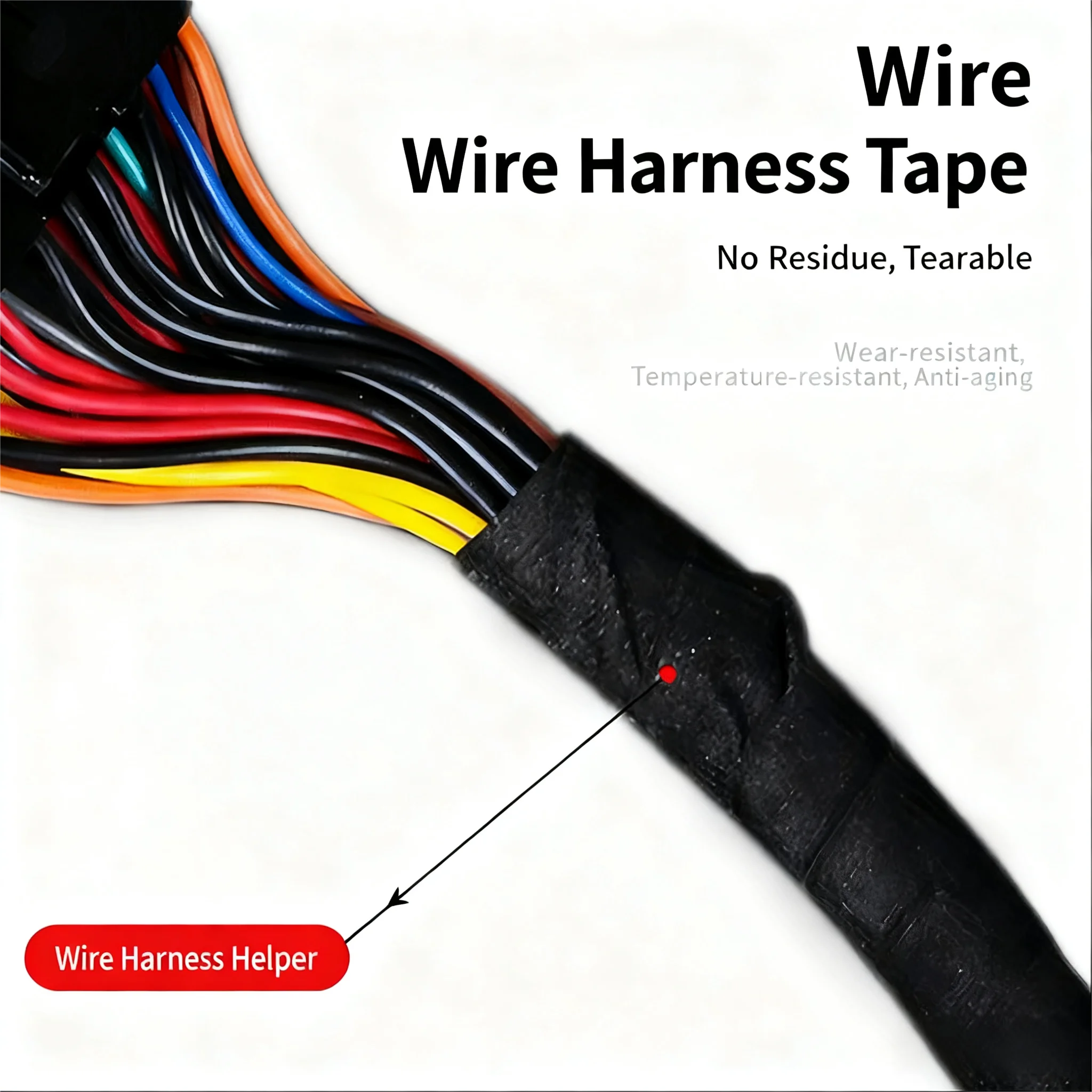

The versatility of this flannel insulation tape makes it suitable for numerous industrial and commercial applications. In automotive manufacturing, it serves as an effective solution for reducing engine compartment noise while providing thermal protection for sensitive electrical components. The tape's heat resistance makes it ideal for masking applications during powder coating, paint curing, and other high-temperature manufacturing processes. Its flame retardant properties ensure safe use in electrical panel installations, wire harness protection, and electronic equipment assembly.

HVAC systems benefit significantly from this tape's dual functionality, as it provides both thermal insulation and acoustic dampening for ductwork and equipment housings. In aerospace applications, the tape's lightweight construction combined with superior performance characteristics makes it valuable for cabin noise reduction and thermal management systems. Manufacturing facilities utilize this product for equipment sound dampening, reducing workplace noise levels and creating more comfortable working environments. The tape also finds extensive use in marine applications, where both corrosion resistance and noise control are essential requirements.

Industrial maintenance teams rely on this tape for temporary repairs and protective applications where both heat resistance and noise reduction are required. Its conformable nature allows it to adapt to irregular surfaces and complex geometries, making it suitable for retrofitting existing equipment with enhanced acoustic and thermal protection. The tape's durability ensures long-term performance in demanding environments, reducing maintenance frequency and associated costs.

Quality Control & Compliance

Manufacturing excellence drives every aspect of this Adhesive Flannel Insulation Tape-High Heat Resistant Flame Retardant Masking Tape for Abnormal Noise Reduction Shock Damping production process. Rigorous quality control protocols ensure consistent performance characteristics across all product batches. The manufacturing facility operates under international quality management systems, implementing comprehensive testing procedures that verify thermal resistance, flame retardant effectiveness, and acoustic performance parameters.

Raw material selection follows strict specifications, with each component undergoing thorough inspection before entering the production process. The flannel substrate meets textile industry standards for durability and performance, while the adhesive system undergoes extensive testing for temperature resistance and bonding strength. Flame retardant additives are sourced from certified suppliers and tested for compliance with relevant safety standards. Environmental testing simulates real-world conditions, ensuring the tape maintains its protective properties under various operational stresses.

Final product validation includes comprehensive performance testing across temperature ranges, acoustic frequency spectrums, and mechanical stress conditions. These quality assurance measures guarantee that every roll of tape meets the demanding requirements of professional users worldwide. Documentation accompanies each product batch, providing traceability and performance verification for critical applications.

Customization & Branding Options

Understanding the diverse needs of global markets, comprehensive customization services accommodate specific application requirements and branding preferences. Custom packaging manufacturer capabilities enable tailored packaging solutions that reflect brand identity while protecting product integrity during shipping and storage. The flexibility extends to various roll configurations, allowing optimization for specific application methods and user preferences.

Private labeling services support distributor and reseller requirements, with custom packaging options that enhance market presence and brand recognition. Technical specifications can be adjusted within performance parameters to meet unique application demands, ensuring optimal performance in specialized environments. Color variations and marking options provide additional customization possibilities for applications requiring visual identification or coding systems.

OEM packaging solutions accommodate large-volume requirements while maintaining consistent quality standards. The customization process involves close collaboration with clients to understand specific needs and develop tailored solutions that exceed expectations. This comprehensive approach ensures that the final product aligns perfectly with intended applications and market requirements.

Packaging & Logistics Support

Professional packaging solutions protect product integrity throughout the global supply chain while optimizing shipping efficiency and storage requirements. The protective packaging design prevents moisture intrusion, physical damage, and contamination that could compromise tape performance. Standardized packaging dimensions facilitate efficient warehousing and inventory management for distributors and end users alike.

Comprehensive logistics support includes flexible shipping options tailored to regional requirements and delivery timelines. The packaging design accommodates various transportation methods while maintaining product quality and performance characteristics. Custom packaging solutions address specific regional preferences and regulatory requirements, ensuring smooth market entry and distribution.

Environmental considerations influence packaging material selection, with sustainable options available for environmentally conscious markets. The packaging includes clear product identification, handling instructions, and storage recommendations to ensure optimal product performance throughout its shelf life. Bulk packaging options serve high-volume users while maintaining individual roll protection and identification capabilities.

Why Choose Us

With over two decades of experience serving international markets, our company has established itself as a trusted metal packaging supplier and innovative materials manufacturer. Our expertise spans multiple industries, from automotive and aerospace to industrial manufacturing and electronics. This extensive experience enables us to understand the unique challenges faced by different sectors and develop solutions that address specific performance requirements.

Our commitment to excellence extends beyond product manufacturing to comprehensive customer support and technical assistance. As a recognized custom tin box supplier and OEM tin packaging solutions provider, we leverage cross-industry knowledge to enhance our tape manufacturing capabilities. This diversified expertise ensures that our Adhesive Flannel Insulation Tape-High Heat Resistant Flame Retardant Masking Tape for Abnormal Noise Reduction Shock Damping benefits from advanced manufacturing techniques and quality control processes developed across multiple product lines.

Global collaboration with leading manufacturers and suppliers ensures access to the latest materials and technologies, enabling continuous product improvement and innovation. Our international presence facilitates responsive customer service and technical support across different time zones and regions. The combination of manufacturing excellence, technical expertise, and customer focus has earned recognition from professional users worldwide, establishing long-term partnerships based on trust and performance.

Conclusion

The Adhesive Flannel Insulation Tape-High Heat Resistant Flame Retardant Masking Tape for Abnormal Noise Reduction Shock Damping represents a significant advancement in multifunctional protective materials. Its unique combination of thermal resistance, flame retardant properties, and acoustic dampening capabilities addresses multiple performance requirements in a single, convenient product. The superior quality construction ensures reliable performance across demanding applications, while comprehensive customization options accommodate diverse market needs. This innovative tape solution delivers exceptional value for professional users seeking effective thermal protection and noise control in challenging operational environments.

| item | value |

| Adhesive | Acrylic |

| Use | MASKING |

| Place of Origin | China |

| Adhesive Side | Single Sided |

| Material | Flannel |

| Type | Insulation Tape |

| Thickness | 0.3mm |

| Adhesive Type | Pressure Sensitive |

| Feature | Heat-resistant |

| Brand Name | YLW |

| Model Number | YLW-R001 |

| Design Printing | Offer Printing |

| cycle length | 10m |

| paper core | Customizable |

| Printing Handling | Offer printing |

| glue | Acrylic |

well

1. who are we?

We are based in Jiangsu, China, start from 2025,sell to Mid East(30.00%),Southeast Asia(20.00%),Central America(20.00%),North America(15.00%),South Asia(15.00%). There are total about - people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

automotive tape

4. why should you buy from us not from other suppliers?

-

5. what services can we provide?

Accepted Delivery Terms: -;

Accepted Payment Currency: -;

Accepted Payment Type: -;

Language Spoken: English