Introduction

In today's demanding automotive industry, reliable insulation and protection solutions are essential for maintaining electrical system integrity and vehicle performance. The Automotive Black PET Flannel Fabric Tape Single Sided Adhesive Heat-Resistant Customizable for Wire Harness Binding Masking represents a premium engineering solution designed specifically for professional automotive applications. This specialized tape combines advanced polyethylene terephthalate substrate technology with superior flannel fabric construction, delivering exceptional performance in harsh automotive environments where traditional tapes fail to meet stringent operational requirements.

Modern vehicle electrical systems demand protection materials that can withstand extreme temperature variations, mechanical stress, and chemical exposure while maintaining consistent adhesive performance. Our automotive-grade PET flannel fabric tape addresses these challenges through innovative material engineering and manufacturing processes that ensure long-term reliability in critical automotive applications. The product serves as an indispensable component for automotive manufacturers, aftermarket service providers, and industrial equipment assemblers who require dependable wire harness protection and masking solutions.

Product Overview

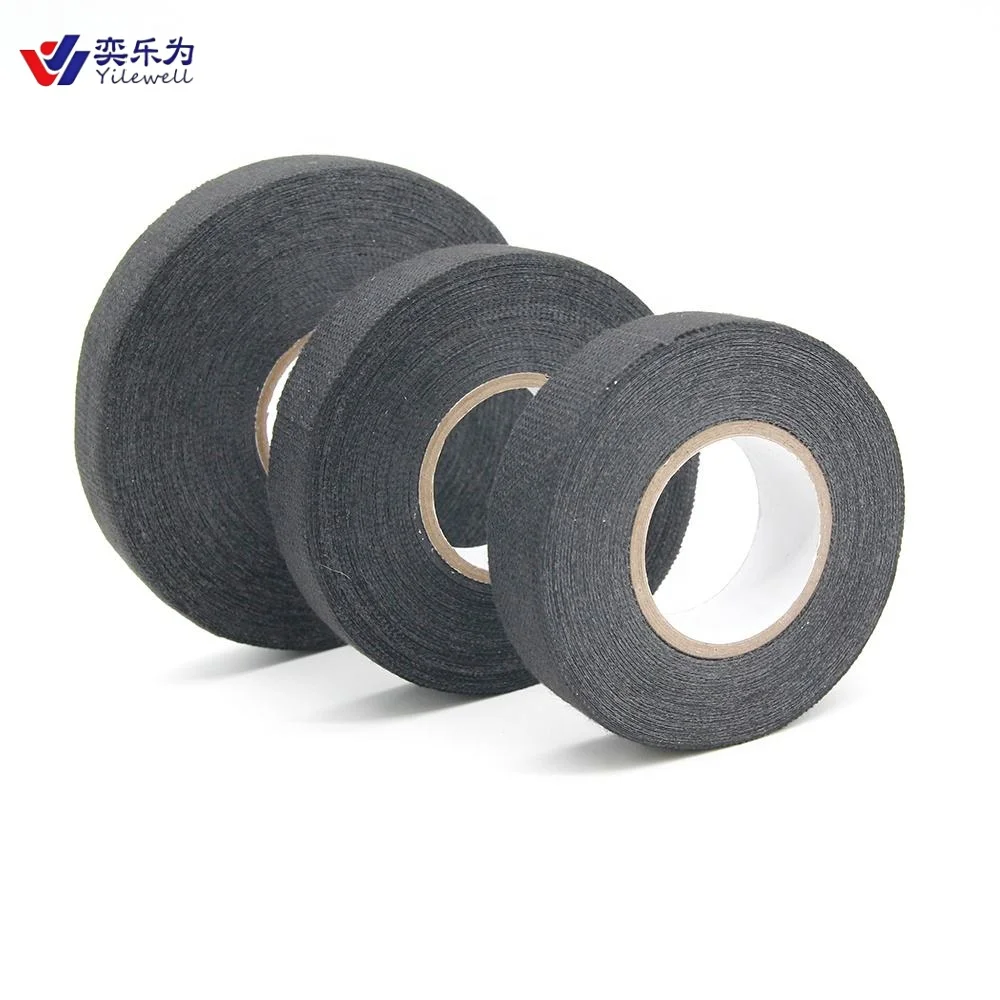

The Automotive Black PET Flannel Fabric Tape Single Sided Adhesive Heat-Resistant Customizable for Wire Harness Binding Masking features a sophisticated construction that integrates high-performance polyethylene terephthalate film with specialized flannel fabric backing. This unique combination creates a tape that offers superior conformability and mechanical strength while maintaining excellent electrical insulation properties. The single-sided adhesive system utilizes advanced polymer chemistry to ensure strong initial tack and long-term adhesion stability across varying environmental conditions.

The black coloration provides professional appearance and UV resistance, making it ideal for visible installations and applications requiring aesthetic consistency. The flannel fabric surface offers excellent handling characteristics and reduces noise generation during wire harness movement, a critical consideration in modern automotive applications where noise, vibration, and harshness control are paramount. The tape's construction allows for easy unwinding and application while preventing adhesive transfer to application tools and equipment.

Features & Benefits

Advanced Material Engineering

The polyethylene terephthalate substrate provides exceptional dimensional stability and chemical resistance, ensuring the tape maintains its protective properties even when exposed to automotive fluids, oils, and cleaning solvents commonly encountered in vehicle environments. The flannel fabric backing enhances tear resistance and provides cushioning protection for delicate wire insulation, preventing damage during installation and throughout the product's service life.

Superior Heat Resistance Performance

Heat resistance represents a critical performance parameter for automotive applications, and this specialized tape excels in high-temperature environments typical of modern vehicle operation. The advanced adhesive formulation maintains bond strength and integrity even when subjected to engine compartment temperatures, ensuring reliable long-term performance without adhesive migration or substrate degradation. This thermal stability makes the product suitable for applications near heat-generating components such as exhaust systems, engine blocks, and transmission assemblies.

Enhanced Adhesive Technology

The single-sided adhesive system employs pressure-sensitive technology that provides immediate bonding without requiring heat activation or curing time. This feature significantly reduces installation time and labor costs while ensuring consistent application results. The adhesive maintains excellent conformability to irregular surfaces and provides reliable adhesion to various substrate materials commonly used in automotive construction, including plastics, metals, and composite materials.

Applications & Use Cases

Wire harness binding represents the primary application for this specialized automotive tape, where it serves to organize, protect, and secure electrical conductor bundles throughout vehicle electrical systems. The tape's conformable nature and strong adhesive bond make it ideal for securing harnesses to vehicle chassis components, preventing chafing and vibration-induced wear while maintaining electrical system integrity. Professional automotive technicians rely on this product for both original equipment assembly and aftermarket repair applications.

Masking applications constitute another significant use case, particularly during automotive painting, coating, and refinishing operations. The tape's clean removal characteristics and chemical resistance make it suitable for protecting sensitive electrical components and wire harnesses during body work and maintenance procedures. The flannel fabric surface provides excellent paint adhesion resistance, preventing unwanted coating buildup that could interfere with electrical system operation or create aesthetic issues.

Industrial equipment manufacturers increasingly specify this automotive-grade tape for applications requiring reliable electrical insulation and mechanical protection. Heavy machinery, construction equipment, and marine applications benefit from the tape's robust construction and environmental resistance properties. The product's versatility extends to aerospace, telecommunications, and renewable energy sectors where high-performance insulation materials are essential for system reliability and safety compliance.

Quality Control & Compliance

Manufacturing excellence begins with rigorous raw material selection and incoming inspection processes that ensure every component meets stringent quality specifications. The production facility implements comprehensive quality management systems that monitor critical parameters throughout the manufacturing process, from substrate preparation through final product packaging. Advanced testing protocols verify adhesive performance, thermal resistance, and mechanical properties to guarantee consistent product quality and reliability.

International automotive industry standards guide product development and manufacturing processes, ensuring compatibility with global vehicle manufacturer requirements and regulatory compliance across multiple markets. The tape undergoes extensive environmental testing including temperature cycling, humidity exposure, chemical resistance evaluation, and accelerated aging studies to validate long-term performance characteristics under real-world operating conditions.

Documentation and traceability systems maintain detailed records of material sources, manufacturing parameters, and quality test results, enabling rapid response to customer inquiries and supporting continuous improvement initiatives. Regular third-party audits and certifications demonstrate ongoing commitment to quality excellence and customer satisfaction in global automotive supply chains.

Customization & Branding Options

Understanding that different automotive applications require specific performance characteristics and dimensional requirements, our manufacturing capabilities support extensive customization options for the Automotive Black PET Flannel Fabric Tape Single Sided Adhesive Heat-Resistant Customizable for Wire Harness Binding Masking. Custom width configurations accommodate various wire harness sizes and installation requirements, while specialized adhesive formulations can be developed to meet unique environmental or performance specifications.

Private labeling and custom packaging options enable distributors and equipment manufacturers to maintain brand consistency while offering premium automotive tape solutions to their customers. Custom core sizes, roll lengths, and packaging configurations support efficient inventory management and reduce handling costs in high-volume applications. Technical documentation and product data sheets can be customized to reflect specific application requirements and performance characteristics.

Color customization beyond the standard black option allows for wire harness coding and identification systems that enhance serviceability and maintenance efficiency. Special marking or printing capabilities support part numbering and traceability requirements in automotive manufacturing environments where component identification and quality control documentation are critical operational requirements.

Packaging & Logistics Support

Efficient packaging design protects product integrity during international shipping while optimizing container utilization and reducing transportation costs. Moisture-resistant packaging materials and protective wrapping ensure the tape maintains its adhesive properties and handling characteristics throughout extended storage periods and challenging shipping conditions. Standardized packaging configurations support automated handling systems and reduce labor requirements in distribution facilities.

Global logistics coordination enables reliable delivery schedules and inventory management support for international customers and distribution partners. Strategic warehouse locations and shipping partnerships facilitate rapid order fulfillment and reduced lead times for urgent automotive production requirements. Flexible shipping options accommodate both large-volume shipments and smaller specialty orders while maintaining cost efficiency and delivery reliability.

Documentation support includes detailed packing lists, material safety data sheets, and customs documentation required for international trade compliance. Tracking systems provide real-time shipment visibility and delivery confirmation, enabling customers to coordinate receiving activities and maintain production schedules without interruption.

Why Choose Us

With extensive experience serving automotive manufacturers and industrial customers across global markets, our company has established a reputation for delivering high-quality specialty tape solutions that meet demanding performance requirements. Our technical expertise in adhesive technology and substrate engineering enables us to develop innovative products that address evolving industry challenges while maintaining cost-effectiveness and reliability.

As a recognized custom tape manufacturer and automotive packaging supplier, we collaborate closely with engineering teams to develop tailored solutions that optimize performance for specific applications. Our manufacturing capabilities support both standard product requirements and specialized custom formulations, enabling customers to source comprehensive tape solutions from a single trusted supplier. Multi-industry expertise across automotive, industrial, and specialty markets provides valuable insights that drive continuous product improvement and innovation.

Commitment to customer success extends beyond product manufacturing to include technical support, application guidance, and ongoing partnership development. Our international presence and local market knowledge enable effective communication and responsive service delivery regardless of geographic location or time zone considerations. Quality certifications and industry recognition demonstrate ongoing dedication to excellence and customer satisfaction in competitive global markets.

Conclusion

The Automotive Black PET Flannel Fabric Tape Single Sided Adhesive Heat-Resistant Customizable for Wire Harness Binding Masking represents a comprehensive solution for demanding automotive applications requiring reliable electrical system protection and professional installation results. Its advanced construction, superior performance characteristics, and extensive customization capabilities make it an essential component for automotive manufacturers, service providers, and industrial equipment builders worldwide. The combination of proven reliability, technical innovation, and manufacturing excellence ensures this specialized tape delivers consistent value and performance in critical applications where failure is not an option.

| item | value |

| Adhesive | Acrylic |

| Use | MASKING |

| Place of Origin | China |

| Adhesive Side | Single Sided |

| Material | Flannel |

| Type | Insulation Tape |

| Thickness | 0.3mm |

| Adhesive Type | Pressure Sensitive |

| Feature | Heat-resistant |

| Brand Name | YLW |

| Model Number | YLW-R001 |

| Design Printing | Offer Printing |

| cycle length | 10m |

| paper core | Customizable |

| Printing Handling | Offer printing |

| glue | Acrylic |

well

1. who are we?

We are based in Jiangsu, China, start from 2025,sell to Mid East(30.00%),Southeast Asia(20.00%),Central America(20.00%),North America(15.00%),South Asia(15.00%). There are total about - people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

automotive tape

4. why should you buy from us not from other suppliers?

-

5. what services can we provide?

Accepted Delivery Terms: -;

Accepted Payment Currency: -;

Accepted Payment Type: -;

Language Spoken: English