Introduction

The automotive industry demands specialized materials that can withstand extreme conditions while providing superior performance across multiple applications. The Automotive Heat-Resistant Bonsai Plant Styling Maintenance Sound Insulation Shock Absorption Adhesive Flannel YLW YLW-R001 10m represents a breakthrough in multifunctional automotive textile solutions. This innovative adhesive flannel combines thermal resistance, acoustic dampening, vibration control, and versatile styling capabilities in a single, high-performance material designed for professional automotive applications.

Engineered for the demanding requirements of modern vehicles, this specialized flannel material addresses critical challenges in automotive manufacturing and maintenance. Its unique composition delivers exceptional heat resistance while maintaining excellent adhesive properties, making it an ideal solution for various automotive environments where traditional materials fall short. The product's versatility extends beyond conventional automotive applications, offering creative possibilities for interior styling and specialized maintenance procedures.

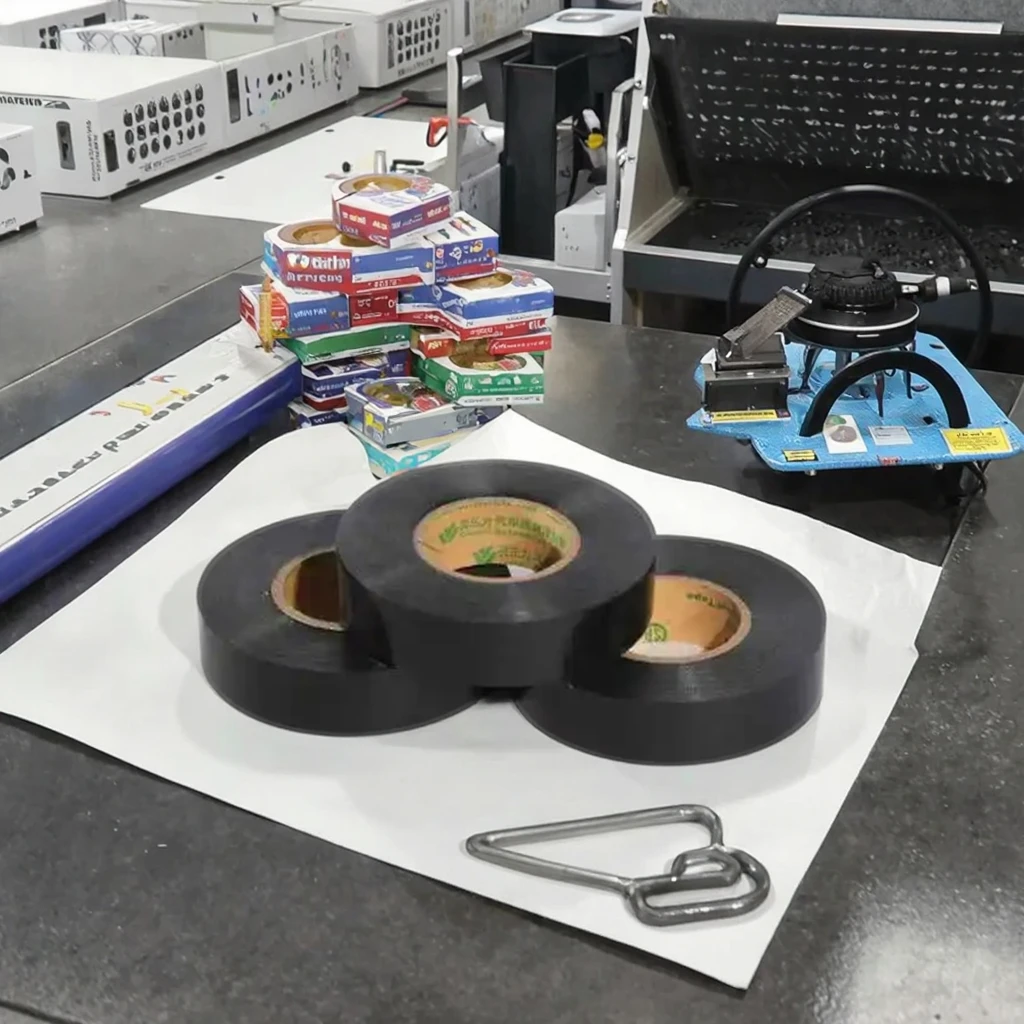

Product Overview

This premium automotive flannel represents a sophisticated engineering achievement in textile technology. The heat-resistant properties enable reliable performance in high-temperature environments commonly found in automotive applications, while the integrated adhesive backing ensures secure attachment to various surfaces. The material's distinctive yellow coloration provides excellent visibility during installation and maintenance procedures, enhancing safety and precision in professional automotive environments.

The Automotive Heat-Resistant Bonsai Plant Styling Maintenance Sound Insulation Shock Absorption Adhesive Flannel YLW YLW-R001 10m combines multiple functional properties in a cohesive solution. Its sound insulation capabilities effectively reduce noise transmission, while the shock absorption characteristics help minimize vibrations and impact forces. These properties make it particularly valuable for automotive applications requiring enhanced comfort, reduced noise levels, and improved overall vehicle performance.

Features & Benefits

Superior Heat Resistance Technology

The advanced heat-resistant formulation ensures consistent performance even under extreme temperature conditions. This thermal stability prevents material degradation, adhesive failure, and performance loss that commonly affects standard automotive textiles. The specialized fiber composition maintains its structural integrity while providing reliable thermal barrier properties essential for automotive applications near heat sources such as engines, exhaust systems, and electrical components.

Multi-Functional Performance Design

Beyond its primary heat resistance, this automotive flannel delivers comprehensive sound insulation and shock absorption capabilities. The material's unique structure effectively dampens acoustic transmission while simultaneously absorbing mechanical vibrations. This dual functionality reduces both airborne noise and structure-borne vibrations, contributing significantly to improved cabin comfort and reduced mechanical stress on automotive components.

Professional-Grade Adhesive System

The integrated adhesive backing provides strong, reliable bonding to various automotive surfaces including metal, plastic, composite materials, and existing automotive textiles. The adhesive formulation maintains its bonding strength across temperature variations while allowing for clean removal when necessary during maintenance or replacement procedures. This professional-grade adhesive system ensures long-term performance without compromising surface integrity.

Applications & Use Cases

The versatile nature of the Automotive Heat-Resistant Bonsai Plant Styling Maintenance Sound Insulation Shock Absorption Adhesive Flannel YLW YLW-R001 10m makes it suitable for numerous automotive applications. In engine compartments, it provides thermal protection and sound dampening around heat-generating components. The material effectively shields sensitive electronic systems from thermal damage while reducing engine noise transmission to passenger compartments.

Interior applications benefit from the material's sound insulation and aesthetic properties. It serves as an effective acoustic barrier behind door panels, dashboard assemblies, and floor sections where road noise reduction is critical. The vibration dampening characteristics make it particularly valuable for reducing rattles and mechanical noise in luxury vehicle applications where cabin refinement is paramount.

Specialized maintenance applications leverage the material's unique combination of properties. During automotive restoration projects, it provides protective covering for sensitive components while offering heat resistance during welding or painting operations. The distinctive styling potential allows for creative interior customization while maintaining functional benefits. Professional automotive services utilize this material for temporary protection during maintenance procedures requiring heat resistance and cushioning properties.

Quality Control & Compliance

Manufacturing standards for this automotive flannel adhere to stringent quality control protocols ensuring consistent performance across production batches. Each roll undergoes comprehensive testing for heat resistance, adhesive strength, acoustic properties, and dimensional stability. The manufacturing process incorporates advanced quality assurance measures that verify material composition, adhesive consistency, and performance characteristics before final approval.

The product meets relevant automotive industry standards for materials used in vehicle manufacturing and maintenance applications. Compliance testing encompasses thermal performance, flame resistance, chemical compatibility, and environmental durability. These comprehensive evaluations ensure the material performs reliably across various climatic conditions and automotive environments while maintaining safety standards required for professional automotive applications.

Environmental considerations are integrated throughout the manufacturing process, with attention to sustainable production practices and material recyclability. The quality control framework includes regular audits of production facilities and ongoing monitoring of material performance in real-world automotive applications, ensuring continuous improvement and reliability enhancement.

Customization & Branding Options

Professional automotive applications often require specialized material configurations beyond standard offerings. Custom thickness variations accommodate specific thermal and acoustic requirements while maintaining the core performance characteristics. The adhesive formulation can be adjusted for different bonding requirements, surface compatibility needs, or removal characteristics depending on the intended application.

Color customization extends beyond the standard yellow option, allowing integration with specific automotive interior themes or corporate branding requirements. Custom printing capabilities enable incorporation of logos, identification markings, or installation instructions directly onto the material surface. These customization options prove particularly valuable for OEM applications, custom tin box suppliers, and specialized automotive manufacturers requiring branded materials.

Dimensional customization accommodates specific automotive applications requiring non-standard widths or specialized cutting patterns. Pre-cut shapes and sizes can be manufactured to match exact component requirements, reducing installation time and material waste. This flexibility supports both large-scale automotive production and specialized restoration projects requiring precise material specifications.

Packaging & Logistics Support

Professional packaging ensures material integrity during transportation and storage while facilitating efficient handling in automotive manufacturing environments. The protective packaging system prevents adhesive contamination, moisture exposure, and physical damage that could compromise material performance. Storage guidelines maintain optimal material properties throughout the supply chain from manufacturing to end-use application.

Logistics support encompasses global distribution capabilities suitable for international automotive manufacturers and suppliers. The packaging design optimizes shipping efficiency while protecting material quality during long-distance transportation. Temperature-controlled storage recommendations ensure adhesive stability and material performance consistency across various climatic conditions.

Inventory management solutions support both large-scale automotive production requirements and smaller specialized applications. Flexible packaging options accommodate different order sizes while maintaining cost efficiency and material quality. The logistics framework supports just-in-time delivery requirements common in modern automotive manufacturing while ensuring adequate safety stock for critical applications.

Why Choose Us

Our company brings extensive experience in developing specialized automotive materials for international markets, with a proven track record of delivering high-performance solutions to automotive manufacturers worldwide. Our global collaboration network includes partnerships with leading automotive suppliers and metal packaging manufacturers, ensuring comprehensive understanding of industry requirements and emerging technology trends.

The Automotive Heat-Resistant Bonsai Plant Styling Maintenance Sound Insulation Shock Absorption Adhesive Flannel YLW YLW-R001 10m represents our commitment to innovative material solutions that address real-world automotive challenges. Our multi-industry expertise encompasses automotive manufacturing, aerospace applications, and specialized industrial uses, providing unique insights into material performance requirements across demanding environments.

Quality assurance protocols developed through years of international automotive supply chain participation ensure consistent material performance and reliability. Our manufacturing capabilities support both high-volume production requirements and specialized custom applications, making us a preferred metal packaging supplier and OEM tin packaging solutions provider for automotive components requiring superior thermal and acoustic performance characteristics.

Conclusion

The Automotive Heat-Resistant Bonsai Plant Styling Maintenance Sound Insulation Shock Absorption Adhesive Flannel YLW YLW-R001 10m delivers exceptional value through its unique combination of thermal resistance, acoustic dampening, and versatile application capabilities. This innovative material solution addresses multiple automotive challenges simultaneously while providing the reliability and performance consistency required for professional automotive applications. Its comprehensive feature set, quality manufacturing standards, and customization flexibility make it an ideal choice for automotive manufacturers, maintenance professionals, and specialized automotive applications requiring superior material performance in demanding environments.

| item | value |

| Adhesive | Acrylic |

| Use | MASKING |

| Place of Origin | China |

| Adhesive Side | Single Sided |

| Material | Flannel |

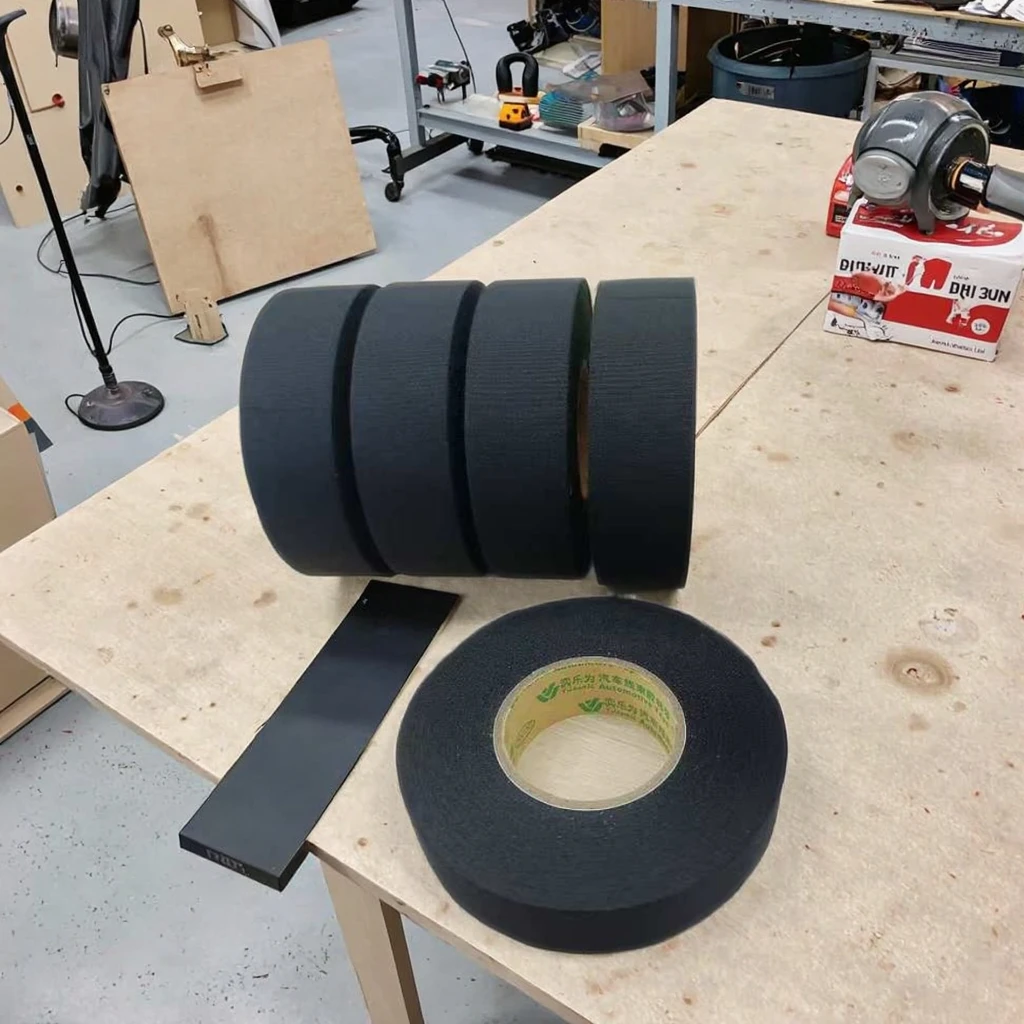

| Type | Insulation Tape |

| Thickness | 0.3mm |

| Adhesive Type | Pressure Sensitive |

| Feature | Heat-resistant |

| Brand Name | YLW |

| Model Number | YLW-R001 |

| Design Printing | Offer Printing |

| cycle length | 10m |

| paper core | Customizable |

| Printing Handling | Offer printing |

| glue | Acrylic |

well

1. who are we?

We are based in Jiangsu, China, start from 2025,sell to Mid East(30.00%),Southeast Asia(20.00%),Central America(20.00%),North America(15.00%),South Asia(15.00%). There are total about - people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

automotive tape

4. why should you buy from us not from other suppliers?

-

5. what services can we provide?

Accepted Delivery Terms: -;

Accepted Payment Currency: -;

Accepted Payment Type: -;

Language Spoken: English