Introduction

Professional adhesive solutions have become increasingly critical across multiple industries, from automotive manufacturing to specialized crafting applications. The Automotive Velvet Wiring Harness Tape Heat-Resistant Bonsai Plant Styling Maintenance Sound Insulation Shock Absorption Adhesive represents a breakthrough in versatile tape technology, offering exceptional performance characteristics that extend far beyond traditional automotive applications. This innovative adhesive solution combines the luxurious texture of velvet with industrial-grade durability, creating a unique product that serves both functional and aesthetic purposes across diverse professional environments.

Modern businesses require adhesive products that can adapt to changing operational demands while maintaining consistent performance standards. This specialized tape addresses the growing need for multi-functional solutions that deliver superior heat resistance, sound dampening capabilities, and reliable adhesion properties. Whether used in automotive wire management, horticultural applications, or precision crafting projects, this product demonstrates remarkable versatility while maintaining the professional quality standards expected by international buyers and distributors.

Product Overview

The Automotive Velvet Wiring Harness Tape Heat-Resistant Bonsai Plant Styling Maintenance Sound Insulation Shock Absorption Adhesive features a sophisticated construction that combines advanced polymer chemistry with textile engineering principles. The velvet surface provides both tactile comfort and functional benefits, while the adhesive backing delivers exceptional bonding strength across various substrate materials. This unique combination makes it particularly valuable for applications requiring both mechanical protection and aesthetic appeal.

The product's heat-resistant properties enable reliable performance in challenging thermal environments commonly encountered in automotive and industrial settings. The specialized formulation maintains adhesive integrity even when exposed to elevated temperatures, ensuring consistent performance throughout extended operational periods. The velvet texture serves dual purposes by providing cushioning properties that enhance shock absorption while creating a professional appearance that meets the aesthetic requirements of visible installations.

Beyond its primary automotive applications, this versatile adhesive solution has found significant acceptance in specialized markets including horticultural maintenance, where its gentle yet secure bonding properties make it ideal for plant training and support applications. The sound insulation characteristics further expand its utility in acoustic management scenarios, making it valuable for professionals working in noise-sensitive environments.

Features & Benefits

Advanced Heat Resistance Technology

The exceptional thermal stability of this automotive velvet wiring harness tape stems from its advanced polymer composition, which maintains adhesive strength and flexibility across wide temperature ranges. This heat-resistant formulation prevents degradation that commonly affects standard adhesive products when exposed to engine compartment conditions or other high-temperature environments. The thermal stability ensures consistent performance in both seasonal temperature variations and continuous high-heat applications, making it particularly valuable for automotive professionals and industrial technicians.

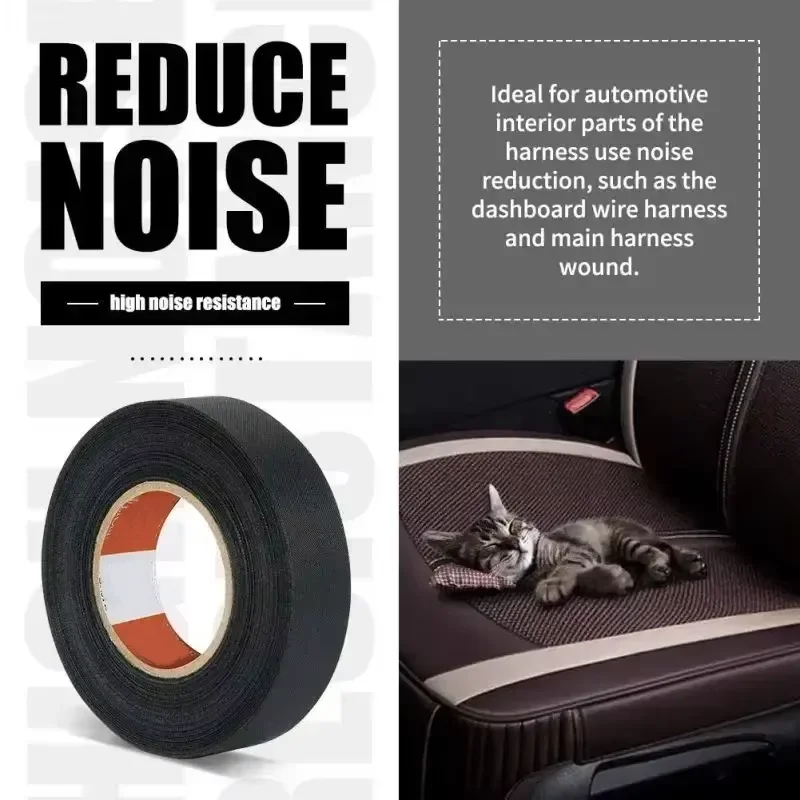

Superior Sound Dampening Properties

The velvet surface texture creates an effective sound insulation barrier that helps reduce unwanted noise transmission in various applications. This acoustic dampening capability proves particularly valuable in automotive installations where wire harnesses pass through cabin areas or near sensitive acoustic zones. The material's dense fiber structure absorbs vibrations and reduces resonance, contributing to overall noise reduction strategies in professional installations.

Enhanced Shock Absorption Characteristics

The cushioning properties inherent in the velvet construction provide excellent shock absorption capabilities that protect sensitive wiring and components from impact damage. This protective characteristic proves essential in automotive applications where wire harnesses may experience vibration, road shock, or installation stress. The elastic properties of the velvet surface help distribute mechanical forces, reducing the likelihood of component fatigue or connection failures over time.

Versatile Adhesion Performance

The specialized adhesive formulation demonstrates reliable bonding characteristics across diverse substrate materials including metals, plastics, textiles, and composite materials. This broad compatibility eliminates the need for multiple adhesive products in complex installations, simplifying inventory management for professional users. The adhesive maintains its bonding strength without leaving residue upon removal, making it suitable for temporary installations and applications requiring periodic maintenance access.

Applications & Use Cases

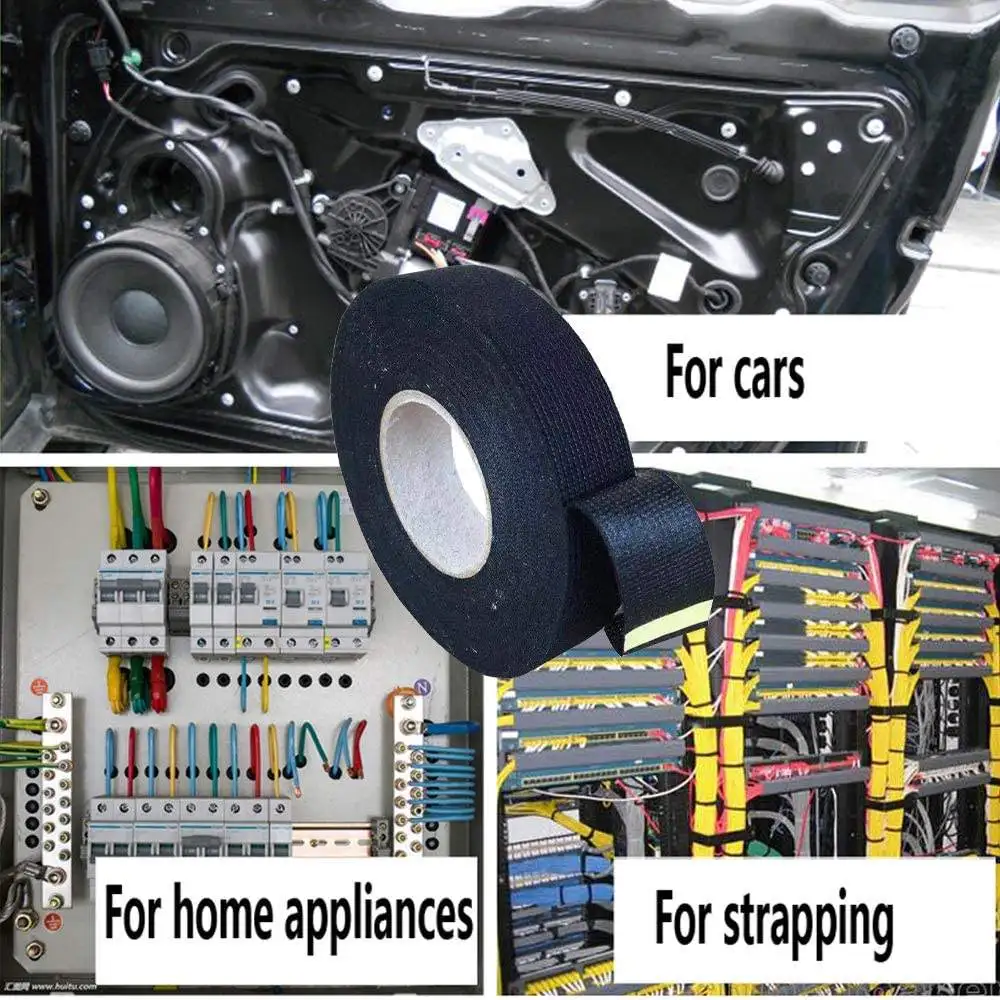

Automotive professionals utilize this Automotive Velvet Wiring Harness Tape Heat-Resistant Bonsai Plant Styling Maintenance Sound Insulation Shock Absorption Adhesive for comprehensive wire management solutions in vehicles ranging from passenger cars to commercial vehicles. The product excels in organizing complex wiring systems while providing protection against heat, moisture, and mechanical damage. Installation teams appreciate its ability to secure harnesses in engine compartments, dashboard assemblies, and other critical automotive systems where both functionality and appearance matter.

The horticultural industry has embraced this versatile tape for bonsai styling and plant training applications, where its gentle adhesive properties and cushioned surface provide secure support without damaging delicate plant tissues. Professional gardeners and nursery operations value its ability to guide branch development and maintain desired plant shapes while allowing for natural growth adjustments. The heat-resistant properties prove beneficial in greenhouse environments where temperature fluctuations might affect conventional adhesive products.

Industrial maintenance teams employ this adhesive solution for equipment vibration dampening and noise control applications. The combination of sound insulation and shock absorption properties makes it particularly effective for securing components in machinery installations where operational noise must be minimized. Manufacturing facilities use it for temporary fixtures and protective applications where the velvet surface prevents scratching or marring of finished surfaces during assembly processes.

Electronics assembly operations benefit from the anti-static properties inherent in the velvet construction, making it suitable for sensitive component handling and temporary securing applications. The controlled adhesion strength allows for repositioning during assembly processes while providing reliable hold when final positioning is achieved. This flexibility proves valuable in prototype development and custom electronics manufacturing where frequent adjustments may be necessary.

Quality Control & Compliance

Manufacturing standards for this automotive velvet wiring harness tape incorporate rigorous quality control protocols that ensure consistent performance characteristics across production batches. Each manufacturing run undergoes comprehensive testing to verify adhesive strength, heat resistance parameters, and dimensional stability under various environmental conditions. The quality assurance process includes accelerated aging tests that simulate extended operational periods, ensuring long-term reliability in demanding applications.

Material composition compliance addresses environmental and safety regulations applicable to automotive and industrial markets worldwide. The adhesive formulation excludes harmful substances commonly restricted in international trade, making it suitable for export to markets with stringent environmental standards. Manufacturing processes incorporate sustainable practices that minimize waste generation while maintaining product quality consistency.

Performance validation testing encompasses thermal cycling, humidity resistance, and adhesive strength measurements that exceed industry standard requirements. These comprehensive testing protocols ensure reliable performance across the diverse environmental conditions encountered in global markets. Documentation supporting quality claims provides transparency for international buyers seeking verified performance data for their specific applications.

Customization & Branding Options

Professional customization services accommodate specific requirements for color matching, width variations, and specialized adhesive formulations tailored to unique application demands. Custom packaging manufacturer capabilities enable branded presentation options that support distributor marketing strategies and end-user recognition programs. These customization services extend to packaging design, product labeling, and technical documentation that reinforces brand identity throughout the supply chain.

Private labeling opportunities allow distributors and importers to establish market presence with professionally packaged products that meet their specific branding requirements. Custom tin box supplier partnerships provide premium packaging solutions that enhance product presentation and protect merchandise during international shipping. The flexibility in packaging options supports various market positioning strategies while maintaining product integrity throughout distribution channels.

Technical customization services address specialized performance requirements including modified adhesive strength, enhanced temperature resistance, or specific dimensional configurations. Engineering support assists customers in developing application-specific solutions that optimize performance for unique operational environments. This collaborative approach ensures that customized products deliver the precise characteristics required for successful implementation in specialized applications.

Packaging & Logistics Support

Comprehensive packaging solutions protect product integrity throughout international distribution while supporting efficient logistics operations. Primary packaging utilizes protective materials that prevent adhesive contamination and maintain velvet surface quality during handling and storage. Secondary packaging configurations optimize shipping efficiency while providing adequate protection against environmental factors encountered during global transportation.

OEM tin packaging solutions offer enhanced protection for high-value shipments and premium market applications where presentation quality directly impacts customer perception. These specialized packaging options incorporate tamper-evident features and protective cushioning that ensures products arrive in optimal condition regardless of shipping duration or handling conditions. The packaging design facilitates easy inventory management and product identification throughout the supply chain.

Logistics support services include documentation assistance for international shipping requirements, customs classification guidance, and coordination with freight forwarding partners experienced in adhesive product transportation. This comprehensive support minimizes shipping delays and ensures compliance with international trade regulations. Packaging optimization services help distributors achieve cost-effective shipping solutions while maintaining product quality standards.

Why Choose Us

Our extensive experience serving international markets for over two decades has established us as a trusted metal packaging supplier with deep understanding of global quality expectations and regulatory requirements. This experience enables us to deliver consistent product quality and reliable service support that international buyers depend upon for their operational success. Our manufacturing capabilities incorporate advanced technology and quality control systems that ensure every product meets the demanding standards expected by professional users worldwide.

Strategic partnerships with leading material suppliers and technology providers enable continuous product innovation and performance improvement initiatives. These collaborative relationships ensure access to the latest adhesive technologies and manufacturing techniques that maintain our competitive advantage in global markets. Our commitment to research and development drives ongoing product enhancement programs that address emerging market needs and application requirements.

Comprehensive customer support services include technical consultation, application guidance, and ongoing product support that extends throughout the customer relationship. Our international sales and support network provides local expertise in key markets while maintaining centralized quality standards and product consistency. This global presence combined with local expertise ensures responsive service delivery regardless of customer location or market requirements.

Conclusion

The Automotive Velvet Wiring Harness Tape Heat-Resistant Bonsai Plant Styling Maintenance Sound Insulation Shock Absorption Adhesive represents a significant advancement in multi-functional adhesive technology, combining exceptional performance characteristics with remarkable versatility across diverse professional applications. Its unique combination of heat resistance, sound dampening properties, and shock absorption capabilities makes it an invaluable solution for automotive professionals, horticultural specialists, and industrial maintenance teams seeking reliable, high-performance adhesive products. The product's ability to deliver consistent results across varying environmental conditions while maintaining aesthetic appeal positions it as a premium solution for quality-conscious international buyers and distributors seeking to offer superior products to their customers.

| item | value |

| Adhesive | Acrylic |

| Use | MASKING |

| Place of Origin | China |

| Adhesive Side | Single Sided |

| Material | Flannel |

| Type | Insulation Tape |

| Thickness | 0.3mm |

| Adhesive Type | Pressure Sensitive |

| Feature | Heat-resistant |

| Brand Name | YLW |

| Model Number | YLW-R001 |

| Design Printing | Offer Printing |

| cycle length | 10m |

| paper core | Customizable |

| Printing Handling | Offer printing |

| glue | Acrylic |

well

1. who are we?

We are based in Jiangsu, China, start from 2025,sell to Mid East(30.00%),Southeast Asia(20.00%),Central America(20.00%),North America(15.00%),South Asia(15.00%). There are total about - people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

automotive tape

4. why should you buy from us not from other suppliers?

-

5. what services can we provide?

Accepted Delivery Terms: -;

Accepted Payment Currency: -;

Accepted Payment Type: -;

Language Spoken: English