Introduction

The automotive industry demands exceptional reliability and performance from every component, including specialized adhesive solutions that secure and protect critical wiring systems. Professional automotive flannel tape represents a cornerstone solution for wire harness protection, cable management, and thermal insulation applications across diverse automotive manufacturing environments. This specialized PET fabric-based adhesive tape combines superior heat resistance with single-sided application convenience, delivering consistent performance in demanding automotive assembly and maintenance operations.

Modern vehicle electrical systems require sophisticated protection mechanisms to ensure long-term functionality and safety compliance. The Custom Black Adhesive Automotive Flannel Tape PET Fabric Single Sided Heat-Resistant for Wire Harness Binding Loom for Masking addresses these critical requirements through advanced material engineering and precision manufacturing processes. This professional-grade tape solution provides comprehensive wire harness binding capabilities while maintaining excellent masking properties for automotive painting and finishing applications.

Product Overview

This automotive-grade flannel tape features a robust PET fabric construction that delivers exceptional durability and thermal stability in challenging automotive environments. The single-sided adhesive configuration provides optimal application flexibility while ensuring secure bonding to various automotive surfaces and cable assemblies. The black coloration offers discrete integration within automotive wire harness systems while providing visual contrast for quality control and maintenance procedures.

The specialized fabric construction incorporates advanced polyester fibers that maintain structural integrity under mechanical stress and temperature fluctuations typical in automotive applications. This Custom Black Adhesive Automotive Flannel Tape PET Fabric Single Sided Heat-Resistant for Wire Harness Binding Loom for Masking demonstrates superior conformability around complex wire routing configurations, ensuring comprehensive protection without compromising cable flexibility or electrical performance.

Professional automotive manufacturers and assembly facilities recognize the importance of reliable wire harness protection solutions that meet stringent industry standards. This flannel tape solution combines proven adhesive technology with engineered fabric substrates to deliver consistent performance across diverse automotive applications, from engine compartment installations to interior harness routing systems.

Features & Benefits

Superior Heat Resistance Properties

The advanced thermal stability characteristics of this automotive flannel tape ensure reliable performance in high-temperature environments commonly encountered in automotive applications. The PET fabric substrate maintains dimensional stability and adhesive integrity even when exposed to elevated temperatures from engine components, exhaust systems, and electrical load conditions. This thermal resistance capability prevents tape degradation, adhesive migration, and performance deterioration that could compromise wire harness protection over extended service periods.

Enhanced Wire Protection Capabilities

The soft flannel surface texture provides gentle contact with wire insulation while offering effective abrasion protection against vibration, movement, and contact with surrounding components. This protective barrier helps prevent wire chafing, insulation damage, and electrical failures that could result from harsh automotive operating conditions. The fabric construction absorbs mechanical stress and distributes loads across the tape width, reducing localized pressure points on individual conductors.

Versatile Application Performance

Beyond wire harness binding applications, this Custom Black Adhesive Automotive Flannel Tape PET Fabric Single Sided Heat-Resistant for Wire Harness Binding Loom for Masking excels in automotive masking operations during painting, coating, and finishing processes. The clean removal characteristics and edge definition properties make it ideal for creating precise masking boundaries while protecting sensitive components from overspray and chemical exposure.

Professional Adhesive Technology

The single-sided adhesive formulation provides strong initial tack and long-term bonding strength while maintaining clean removability when required for maintenance or modification procedures. The adhesive chemistry resists automotive fluids, solvents, and environmental contaminants commonly encountered in vehicle manufacturing and service environments. This chemical resistance ensures maintained bonding performance throughout the product lifecycle.

Applications & Use Cases

Automotive wire harness assembly represents the primary application domain for this specialized flannel tape solution. Professional harness manufacturers utilize this tape for bundling multiple conductors into organized assemblies, providing both mechanical protection and organizational structure for complex automotive electrical systems. The tape facilitates efficient routing through vehicle chassis components while maintaining proper conductor spacing and preventing electromagnetic interference between signal and power circuits.

Engine compartment applications demand exceptional thermal and chemical resistance from wire protection materials. This Custom Black Adhesive Automotive Flannel Tape PET Fabric Single Sided Heat-Resistant for Wire Harness Binding Loom for Masking provides reliable performance in these challenging environments, protecting critical engine management wiring from heat, vibration, and fluid exposure. The tape maintains flexibility and adhesion despite temperature cycling and mechanical stress from engine operation.

Automotive painting and refinishing operations benefit from the masking capabilities of this flannel tape solution. Body shops and manufacturing facilities use this tape to protect wire harnesses, connectors, and electrical components during spray painting, powder coating, and surface treatment procedures. The clean removal characteristics prevent adhesive residue while ensuring sharp paint lines and professional finishing quality.

Interior automotive applications require discrete wire management solutions that maintain aesthetic appeal while providing functional protection. This black flannel tape integrates seamlessly with interior trim components and upholstery materials, offering invisible wire routing and protection for entertainment systems, navigation equipment, and comfort control wiring. The soft fabric surface prevents scratching of interior surfaces during installation and service procedures.

Quality Control & Compliance

Manufacturing excellence begins with rigorous material selection and quality verification processes that ensure consistent performance characteristics across production batches. Each roll of this automotive flannel tape undergoes comprehensive testing protocols that verify adhesive strength, thermal stability, dimensional accuracy, and chemical resistance properties. These quality control measures guarantee that every product meets the demanding requirements of automotive manufacturing environments.

International automotive industry standards guide the development and production of this Custom Black Adhesive Automotive Flannel Tape PET Fabric Single Sided Heat-Resistant for Wire Harness Binding Loom for Masking. Compliance with relevant automotive specifications ensures compatibility with global vehicle manufacturing processes and regulatory requirements. The manufacturing facility maintains certification alignment with industry quality management systems, providing confidence in product consistency and traceability.

Environmental and safety considerations form integral components of the quality assurance program. Raw material sourcing emphasizes sustainable practices and responsible manufacturing processes that minimize environmental impact while maintaining superior product performance. Safety testing protocols verify that the tape materials meet automotive industry requirements for outgassing, flammability, and toxicity standards essential for vehicle interior applications.

Continuous improvement initiatives drive ongoing refinement of manufacturing processes and product performance characteristics. Customer feedback integration and field performance monitoring inform product development activities that enhance tape performance, application convenience, and long-term reliability. This commitment to excellence ensures that the flannel tape solution evolves to meet changing automotive industry requirements and technological advances.

Customization & Branding Options

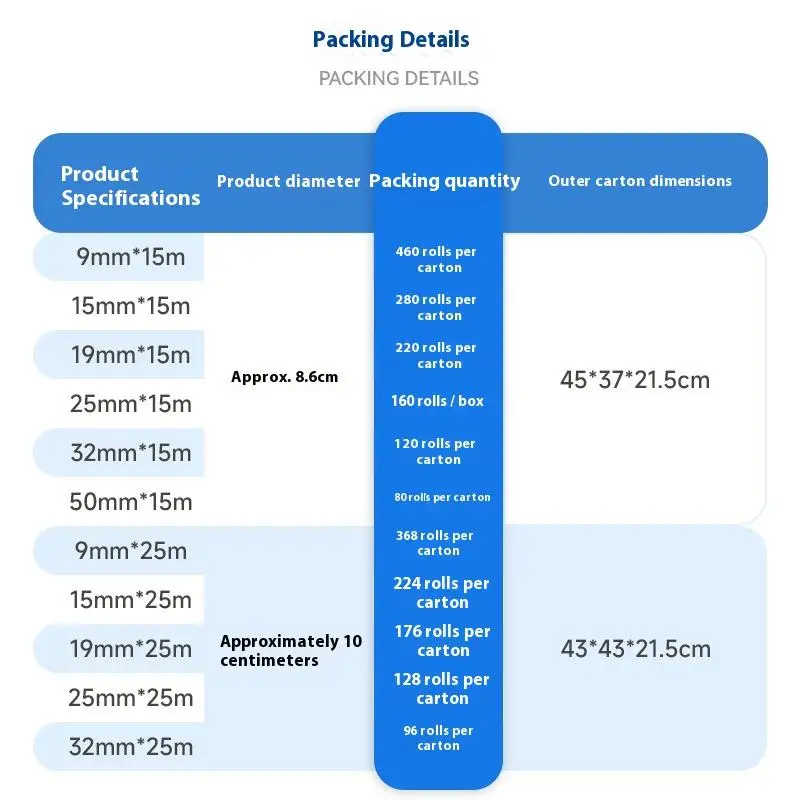

Professional automotive manufacturers often require specialized tape solutions that align with specific application requirements and corporate branding initiatives. Custom width configurations accommodate diverse wire harness designs and routing constraints, enabling optimal tape utilization and installation efficiency. The manufacturing facility supports custom width slitting services that provide precise dimensional control for specialized automotive applications.

Color customization capabilities extend beyond the standard black configuration to include custom color matching services for specific automotive manufacturer requirements. Custom colors enable visual coding systems for different wire harness types, voltage levels, or functional categories, enhancing assembly accuracy and maintenance efficiency. The color stability characteristics ensure that custom colors maintain appearance integrity throughout the product service life.

Private labeling services provide automotive manufacturers and distributors with branded tape solutions that reinforce corporate identity and quality positioning. Custom packaging options include branded core labels, carton printing, and documentation that align with customer branding requirements. These customization services support OEM tin packaging solutions and custom tin box supplier requirements while maintaining product performance integrity.

Technical customization options address specific automotive application challenges through modified adhesive formulations, enhanced temperature ratings, or specialized fabric treatments. The engineering team collaborates with customers to develop tailored solutions that optimize performance for unique automotive environments or application requirements. This collaborative approach ensures that customized tape solutions deliver superior performance while maintaining manufacturing efficiency and cost-effectiveness.

Packaging & Logistics Support

Professional packaging solutions protect tape quality during transportation and storage while facilitating efficient inventory management and application processes. Individual rolls receive protective wrapping that prevents contamination and adhesive degradation during handling and storage. Carton packaging provides additional protection while enabling efficient palletization and warehouse management for large volume orders.

Global distribution capabilities ensure reliable product availability across international automotive manufacturing locations. The logistics network supports efficient delivery to automotive assembly facilities, wire harness manufacturers, and aftermarket service providers worldwide. Strategic inventory positioning minimizes lead times while maintaining product freshness and performance characteristics.

Packaging sustainability initiatives emphasize recyclable materials and reduced packaging waste while maintaining adequate product protection. The packaging design balances environmental responsibility with practical handling requirements for automotive manufacturing environments. These efforts align with automotive industry sustainability goals and corporate environmental responsibility programs.

This Custom Black Adhesive Automotive Flannel Tape PET Fabric Single Sided Heat-Resistant for Wire Harness Binding Loom for Masking benefits from specialized handling procedures that preserve adhesive performance and fabric integrity throughout the distribution chain. Temperature-controlled storage and handling protocols prevent premature aging and maintain optimal application characteristics. Documentation systems provide traceability and lot identification for quality assurance and inventory management purposes.

Why Choose Us

With extensive experience serving the global automotive industry across multiple decades, our company has established a reputation for delivering innovative adhesive solutions that meet the evolving demands of modern vehicle manufacturing. Our international market presence spans major automotive manufacturing regions, enabling close collaboration with leading automotive manufacturers and tier-one suppliers worldwide. This global perspective ensures that our flannel tape solutions incorporate best practices and emerging technologies from diverse automotive markets.

As a recognized metal packaging manufacturer and custom tin box supplier, our expertise extends beyond automotive applications to include comprehensive packaging solutions that support diverse industrial requirements. Our OEM tin packaging solutions and metal packaging supplier capabilities demonstrate the breadth of engineering and manufacturing expertise that informs our automotive tape development programs. This multi-industry experience enables innovative approaches to automotive adhesive challenges through cross-pollination of technologies and best practices.

Technical innovation drives our product development initiatives, resulting in advanced flannel tape solutions that exceed conventional performance limitations. Our research and development capabilities focus on emerging automotive technologies, including electric vehicle requirements, autonomous vehicle systems, and advanced driver assistance applications. This forward-looking approach ensures that our Custom Black Adhesive Automotive Flannel Tape PET Fabric Single Sided Heat-Resistant for Wire Harness Binding Loom for Masking remains relevant for future automotive applications.

Customer collaboration forms the foundation of our business approach, enabling customized solutions that address specific automotive manufacturer requirements and application challenges. Our technical support team works closely with automotive engineers to optimize tape selection, application procedures, and performance outcomes. This collaborative partnership approach ensures successful integration of flannel tape solutions into automotive manufacturing processes while maximizing operational efficiency and product reliability.

Conclusion

The Custom Black Adhesive Automotive Flannel Tape PET Fabric Single Sided Heat-Resistant for Wire Harness Binding Loom for Masking represents a comprehensive solution for demanding automotive wire protection and masking applications. Through advanced PET fabric construction, superior heat resistance properties, and professional adhesive technology, this flannel tape delivers reliable performance across diverse automotive manufacturing and service environments. The combination of mechanical protection capabilities, thermal stability, and application versatility makes this tape solution indispensable for modern automotive electrical system requirements.

Professional automotive manufacturers recognize the critical importance of reliable wire harness protection solutions that maintain performance integrity throughout extended service periods. This specialized flannel tape addresses these requirements through proven material technology, rigorous quality control processes, and comprehensive customization capabilities that align with specific automotive application needs. The resulting solution provides exceptional value through enhanced reliability, improved installation efficiency, and long-term performance consistency that supports automotive industry quality objectives and customer satisfaction goals.

| item | value |

| Adhesive | Acrylic |

| Use | MASKING |

| Place of Origin | China |

| Adhesive Side | Single Sided |

| Material | Flannel |

| Type | Insulation Tape |

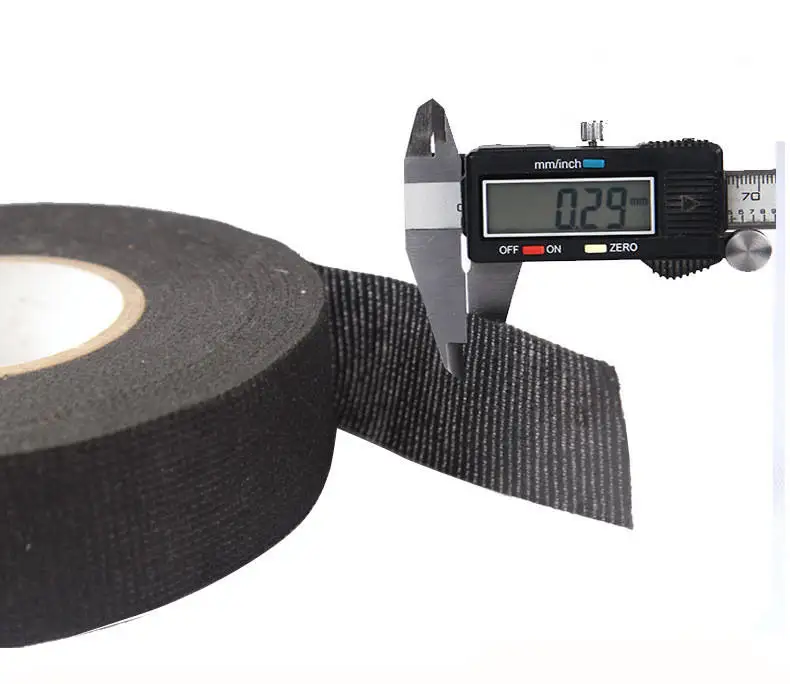

| Thickness | 0.3mm |

| Adhesive Type | Pressure Sensitive |

| Feature | Heat-resistant |

| Brand Name | YLW |

| Model Number | YLW-R001 |

| Design Printing | Offer Printing |

| cycle length | 10m |

| paper core | Customizable |

| Printing Handling | Offer printing |

| glue | Acrylic |

well

1. who are we?

We are based in Jiangsu, China, start from 2025,sell to Mid East(30.00%),Southeast Asia(20.00%),Central America(20.00%),North America(15.00%),South Asia(15.00%). There are total about - people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

automotive tape

4. why should you buy from us not from other suppliers?

-

5. what services can we provide?

Accepted Delivery Terms: -;

Accepted Payment Currency: -;

Accepted Payment Type: -;

Language Spoken: English