Introduction

The automotive industry demands precision-engineered solutions that deliver consistent performance under challenging operating conditions. Wire harness systems, which serve as the nervous system of modern vehicles, require specialized binding materials that can withstand extreme temperatures, vibrations, and environmental stresses. Professional-grade PET loom fabric tapes have emerged as the industry standard for securing and protecting critical wiring assemblies throughout diverse automotive applications.

This Custom-Made PET Loom Fabric Tape Single Sided Black Adhesive for Automotive Wire Harness Binding Heat-Resistant Feature represents a breakthrough in automotive wiring protection technology. Engineered specifically for demanding automotive environments, this specialized tape combines the inherent strength of polyethylene terephthalate substrate with advanced adhesive formulations to deliver exceptional binding performance. The black coloration provides professional aesthetics while offering enhanced UV resistance properties essential for long-term durability.

Product Overview

The foundation of effective wire harness management lies in selecting appropriate binding materials that balance flexibility, strength, and environmental resistance. This premium PET loom fabric tape incorporates advanced polymer technology to create a robust substrate that maintains structural integrity across wide temperature ranges. The single-sided adhesive configuration ensures precise application control while providing strong bonding characteristics essential for automotive assembly processes.

Manufacturing excellence defines every aspect of this specialized automotive tape solution. The PET substrate undergoes careful processing to achieve optimal fabric weave density, ensuring consistent thickness and uniform surface characteristics. Advanced adhesive chemistry creates strong bonds with wire insulation materials while maintaining removability for service applications. The black pigmentation system provides consistent color matching across production batches while enhancing visual identification during assembly operations.

Quality automotive manufacturers recognize the critical importance of selecting binding materials that complement modern wire harness designs. This Custom-Made PET Loom Fabric Tape Single Sided Black Adhesive for Automotive Wire Harness Binding Heat-Resistant Feature addresses these requirements through carefully engineered material properties that support efficient installation procedures while ensuring long-term reliability performance.

Features & Benefits

Advanced Material Properties

The polyethylene terephthalate substrate provides exceptional dimensional stability across automotive operating temperature ranges. This thermoplastic polymer exhibits minimal thermal expansion characteristics, ensuring consistent binding tension regardless of environmental conditions. The fabric weave structure distributes mechanical stresses evenly, preventing localized stress concentrations that could compromise wire protection integrity.

Superior heat resistance capabilities distinguish this professional-grade binding solution from conventional tape alternatives. The PET substrate maintains structural properties at elevated temperatures commonly encountered in engine compartment applications. Advanced polymer cross-linking ensures the material retains flexibility and tensile strength even during prolonged exposure to thermal cycling conditions typical of automotive service environments.

Adhesive Performance Excellence

The single-sided adhesive formulation incorporates specialized polymer chemistry designed for automotive wire insulation compatibility. This pressure-sensitive adhesive creates strong initial bonds while allowing repositioning during installation procedures. The adhesive maintains consistent bonding characteristics across wide temperature ranges, ensuring reliable performance from initial assembly through extended service life.

Careful adhesive thickness control ensures optimal conformability to irregular wire bundle surfaces while preventing excessive buildup that could interfere with harness routing. The black adhesive coloration matches the substrate appearance, creating professional-looking installations that meet automotive quality standards. Advanced adhesive aging characteristics maintain bonding strength throughout typical automotive service intervals.

Application Advantages

Installation efficiency benefits significantly from the engineered flexibility characteristics of this specialized PET loom fabric tape. The material conforms readily to complex wire bundle geometries while maintaining consistent binding tension. Controlled adhesive release properties facilitate smooth unwinding during application, reducing installation time and improving assembly line productivity.

The black coloration provides excellent visual contrast against light-colored wire insulation, enabling quick identification of binding locations during service procedures. This color choice also minimizes visible contamination effects that could compromise professional appearance standards. UV resistance properties ensure color stability throughout extended exposure periods, maintaining aesthetic quality over extended service life.

Applications & Use Cases

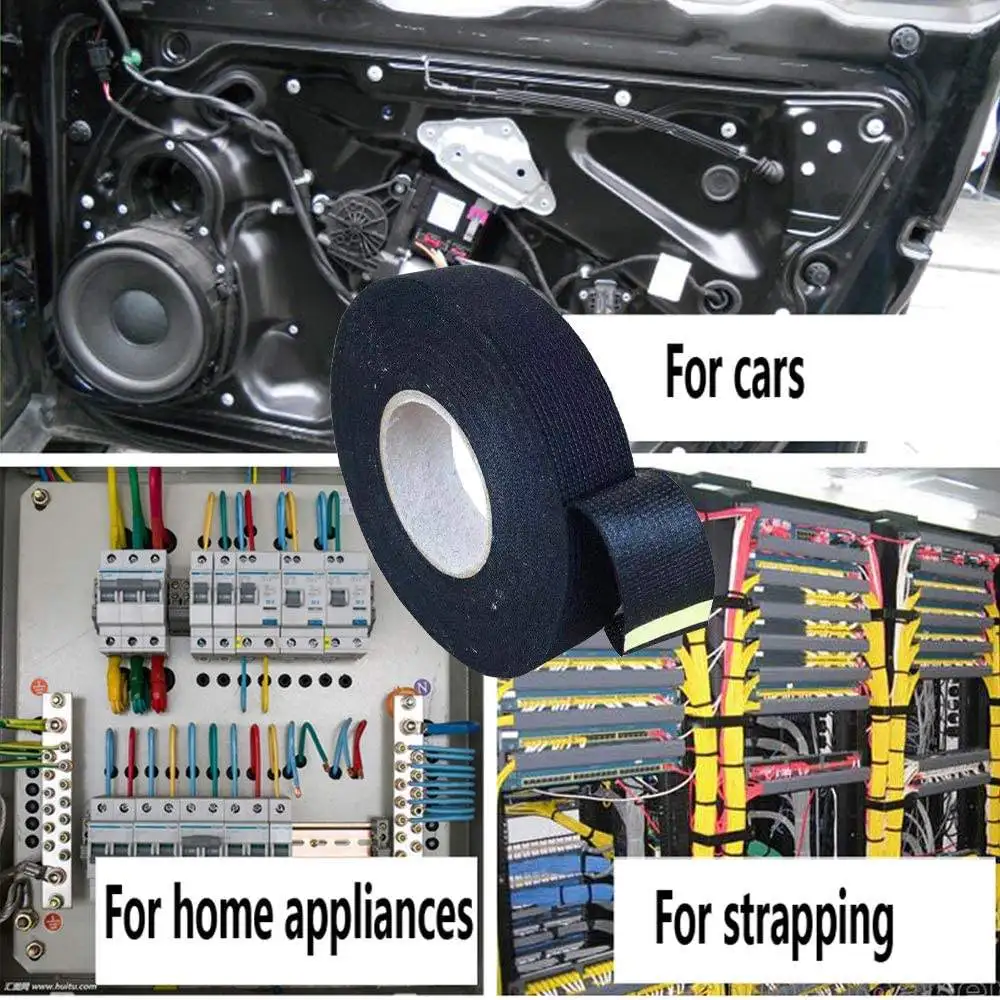

Automotive wire harness applications span diverse vehicle systems, each presenting unique environmental challenges and performance requirements. Engine compartment installations subject binding materials to extreme temperature variations, chemical exposure, and mechanical vibrations. This Custom-Made PET Loom Fabric Tape Single Sided Black Adhesive for Automotive Wire Harness Binding Heat-Resistant Feature excels in these demanding conditions through superior material properties and adhesive performance.

Interior cabin applications benefit from the professional appearance and consistent performance characteristics of this specialized binding solution. Dashboard wiring assemblies require materials that maintain flexibility during temperature cycling while providing secure wire positioning. The heat-resistant properties ensure reliable performance even in vehicles exposed to extended direct sunlight exposure conditions.

Underhood applications present particularly challenging conditions including exposure to engine fluids, road salt, and extreme temperature variations. The PET substrate resists chemical degradation from common automotive fluids while maintaining structural integrity. Advanced adhesive formulations resist moisture penetration that could compromise bonding effectiveness in these harsh operating environments.

Transmission and drivetrain wiring systems require binding materials capable of withstanding continuous vibration and thermal cycling. The fabric weave structure provides excellent vibration dampening characteristics while distributing mechanical stresses across the binding area. This reduces fatigue-related failures that could compromise wire protection integrity during extended service periods.

Quality Control & Compliance

Stringent quality assurance protocols govern every aspect of production from raw material selection through final product packaging. Advanced testing procedures verify adhesive bonding strength, temperature resistance, and dimensional stability characteristics. Statistical process control systems monitor critical quality parameters to ensure consistent product performance across all production batches.

Comprehensive material testing programs evaluate long-term performance characteristics under accelerated aging conditions. Environmental stress testing simulates automotive operating conditions including temperature cycling, humidity exposure, and chemical compatibility. These rigorous evaluation procedures ensure product reliability throughout typical automotive service life requirements.

International quality standards compliance ensures compatibility with global automotive manufacturing processes and requirements. Regular third-party testing verification maintains certification currency while providing independent validation of performance claims. Documentation systems provide complete traceability from raw materials through finished product delivery, supporting automotive quality system requirements.

Advanced analytical testing capabilities verify chemical composition, physical properties, and performance characteristics against established specifications. Precision measurement systems ensure dimensional accuracy while surface analysis techniques confirm adhesive coverage uniformity. These comprehensive quality measures ensure every product batch meets demanding automotive industry standards.

Customization & Branding Options

Flexible manufacturing capabilities enable precise customization to meet specific automotive application requirements. Width variations accommodate different wire bundle sizes while maintaining consistent material properties across all dimensions. Custom length configurations optimize material utilization while reducing waste in high-volume production applications.

Advanced printing capabilities support custom marking requirements including part numbers, specification codes, and traceability information. Digital printing technology ensures precise marking placement while maintaining adhesive performance characteristics. Custom packaging options support efficient integration into existing automotive assembly processes and inventory management systems.

Specialized adhesive formulations address unique automotive requirements including enhanced chemical resistance, modified temperature ranges, or specific bonding characteristics. Custom color matching services support brand identity requirements while maintaining performance standards. These customization capabilities ensure optimal compatibility with specific automotive assembly processes and quality requirements.

Private labeling services enable automotive manufacturers and suppliers to maintain brand consistency across their product portfolios. Professional packaging design supports marketing objectives while providing essential technical information. Custom documentation packages include technical data sheets, application guidelines, and quality certifications tailored to specific customer requirements.

Packaging & Logistics Support

Efficient packaging systems protect product integrity during transportation while supporting automated handling equipment requirements. Advanced packaging materials resist moisture penetration and physical damage throughout extended storage periods. Standardized packaging dimensions optimize shipping efficiency while reducing transportation costs and environmental impact.

Comprehensive logistics support includes flexible shipping arrangements tailored to customer requirements and production schedules. Advanced inventory management systems ensure consistent product availability while minimizing working capital requirements. Just-in-time delivery capabilities support lean manufacturing processes and reduce warehouse space requirements.

International shipping expertise ensures compliance with customs regulations and documentation requirements across global markets. Specialized packaging for international shipments provides additional protection during extended transit periods. Professional logistics coordination minimizes delivery delays while maintaining product quality throughout the supply chain.

Sustainable packaging initiatives incorporate recycled materials and minimize packaging waste while maintaining product protection standards. Returnable packaging options reduce environmental impact for high-volume customers while providing cost advantages. These environmental considerations support corporate sustainability objectives while maintaining operational efficiency.

Why Choose Us

Our company brings extensive experience in developing specialized adhesive solutions for demanding automotive applications across international markets. Years of collaboration with leading automotive manufacturers have refined our understanding of industry requirements and quality expectations. This expertise translates directly into superior product performance and reliable supply chain support for customers worldwide.

As a recognized metal packaging supplier and custom adhesive solutions provider, we maintain comprehensive manufacturing capabilities that support diverse customer requirements. Our global presence enables responsive customer support while ensuring consistent product quality across all markets. Advanced research and development capabilities drive continuous product improvement and innovation in automotive binding solutions.

Quality certification programs validate our commitment to excellence while ensuring compliance with international automotive standards. Regular audits by major automotive manufacturers confirm our quality systems effectiveness and continuous improvement initiatives. These certifications provide customers with confidence in product reliability and supply chain stability.

Comprehensive technical support services include application engineering assistance, custom product development, and ongoing performance optimization. Our technical team works closely with customers to identify optimal solutions for specific applications while ensuring seamless integration into existing manufacturing processes. This collaborative approach ensures maximum value from our Custom-Made PET Loom Fabric Tape Single Sided Black Adhesive for Automotive Wire Harness Binding Heat-Resistant Feature.

Conclusion

The Custom-Made PET Loom Fabric Tape Single Sided Black Adhesive for Automotive Wire Harness Binding Heat-Resistant Feature represents the pinnacle of automotive binding technology, combining advanced material science with proven manufacturing excellence. This specialized solution addresses the critical requirements of modern automotive wire harness applications through superior heat resistance, exceptional adhesive performance, and reliable long-term durability. The professional black appearance and consistent quality characteristics make this product an ideal choice for demanding automotive assembly operations where performance and reliability cannot be compromised. Investment in this premium binding solution delivers measurable value through improved installation efficiency, enhanced product reliability, and reduced long-term maintenance requirements across diverse automotive applications.

| item | value |

| Adhesive | Acrylic |

| Use | MASKING |

| Place of Origin | China |

| Adhesive Side | Single Sided |

| Material | Flannel |

| Type | Insulation Tape |

| Thickness | 0.3mm |

| Adhesive Type | Pressure Sensitive |

| Feature | Heat-resistant |

| Brand Name | YLW |

| Model Number | YLW-R001 |

| Design Printing | Offer Printing |

| cycle length | 10m |

| paper core | Customizable |

| Printing Handling | Offer printing |

| glue | Acrylic |

well

1. who are we?

We are based in Jiangsu, China, start from 2025,sell to Mid East(30.00%),Southeast Asia(20.00%),Central America(20.00%),North America(15.00%),South Asia(15.00%). There are total about - people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

automotive tape

4. why should you buy from us not from other suppliers?

-

5. what services can we provide?

Accepted Delivery Terms: -;

Accepted Payment Currency: -;

Accepted Payment Type: -;

Language Spoken: English