Introduction

In today's demanding automotive and industrial environments, reliable electrical insulation solutions are essential for maintaining operational safety and performance. The Electrical Insulation Tape Heat-resistant Adhesive Single Sided Pressure Sensitive Masking 19mm for Car Cable Harness Wiring represents a professional-grade solution designed to meet the stringent requirements of modern electrical applications. This specialized insulation tape combines superior adhesive properties with exceptional heat resistance, making it an indispensable component for automotive professionals, electrical contractors, and industrial maintenance teams worldwide.

As electrical systems become increasingly complex and operate under more challenging conditions, the need for dependable insulation materials has never been greater. This premium electrical insulation tape addresses these challenges by providing consistent performance across a wide range of temperatures and environmental conditions, ensuring that critical electrical connections remain secure and protected throughout their operational lifespan.

Product Overview

The Electrical Insulation Tape Heat-resistant Adhesive Single Sided Pressure Sensitive Masking 19mm for Car Cable Harness Wiring is engineered specifically for demanding electrical applications where traditional insulation materials may fail. This professional-grade tape features a robust construction that combines a durable backing material with a high-performance pressure-sensitive adhesive system, creating a reliable barrier against electrical hazards while maintaining flexibility and ease of application.

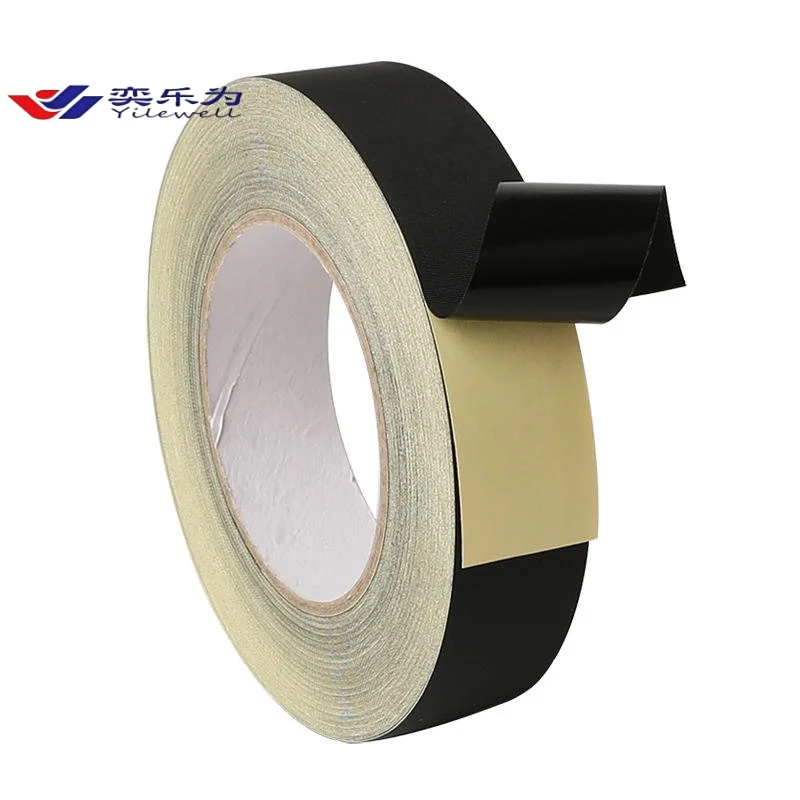

The single-sided design optimizes the tape's functionality for specific applications where adhesion is required on only one surface, allowing for cleaner installations and reduced material waste. The pressure-sensitive adhesive technology ensures immediate bonding upon application, eliminating the need for additional heat activation or curing time. This characteristic makes the tape particularly valuable in time-sensitive repair situations and production environments where efficiency is paramount.

Manufactured to meet the rigorous demands of automotive cable harness applications, this insulation tape demonstrates exceptional conformability to irregular surfaces and tight bend radii commonly encountered in vehicle wiring systems. The tape's construction maintains its integrity even when subjected to the vibrations, temperature fluctuations, and mechanical stresses typical of automotive environments.

Features & Benefits

Superior Heat Resistance Performance

The exceptional heat resistance capabilities of this electrical insulation tape make it suitable for applications where elevated temperatures are a constant concern. The specialized formulation maintains its adhesive strength and insulation properties across a broad temperature range, ensuring reliable performance in engine compartments, industrial machinery, and other high-temperature environments. This thermal stability prevents adhesive migration, backing degradation, and loss of insulation effectiveness that can occur with inferior products.

Advanced Pressure-Sensitive Adhesive Technology

The pressure-sensitive adhesive system employed in this tape provides immediate, strong adhesion without requiring heat activation or solvent evaporation. This technology ensures consistent bonding performance across various substrate materials commonly found in electrical applications, including plastics, metals, and rubber compounds. The adhesive maintains its tackiness over extended periods, allowing for repositioning during installation while providing permanent adhesion once properly applied.

Optimal Width for Versatile Applications

The carefully selected width of this insulation tape strikes an ideal balance between coverage efficiency and material economy. This dimension provides adequate coverage for most standard electrical connections while minimizing waste and ensuring cost-effective usage. The width also facilitates easy handling during application, reducing installation time and improving overall productivity in both manufacturing and repair scenarios.

Enhanced Durability and Longevity

Constructed with premium materials selected for their long-term stability, this electrical insulation tape resists common failure modes such as cracking, peeling, and adhesive degradation. The robust backing material maintains its flexibility over time, preventing the brittleness that can develop in inferior products exposed to temperature cycling and environmental stresses. This durability translates to reduced maintenance requirements and extended service intervals for electrical installations.

Applications & Use Cases

The Electrical Insulation Tape Heat-resistant Adhesive Single Sided Pressure Sensitive Masking 19mm for Car Cable Harness Wiring finds extensive application across multiple industries and use cases. In automotive manufacturing and repair, this tape serves as a critical component for protecting and organizing complex wiring harnesses that snake throughout modern vehicles. The tape's ability to withstand the harsh conditions found in engine bays, including exposure to oil, coolant, and extreme temperatures, makes it invaluable for securing and insulating electrical connections in these challenging environments.

Industrial maintenance professionals rely on this specialized insulation tape for equipment repairs and electrical system upgrades in manufacturing facilities. The tape's quick application and immediate adhesion properties make it particularly useful for emergency repairs where minimizing downtime is essential. Its compatibility with various cable types and electrical components ensures versatile application across different industrial sectors, from food processing to heavy manufacturing.

Electrical contractors and technicians appreciate the tape's performance in both new construction and retrofit applications. Whether securing temporary connections during installation or providing permanent insulation for finished electrical work, the tape's reliable performance reduces callbacks and ensures code compliance. The masking properties also make it suitable for protecting sensitive components during painting or coating operations in electrical enclosures.

Marine and aerospace applications benefit from the tape's resistance to environmental extremes and its ability to maintain adhesion in high-vibration environments. The tape's chemical resistance properties make it suitable for use in environments where exposure to fuels, hydraulic fluids, and cleaning solvents is common, ensuring long-term reliability in these demanding applications.

Quality Control & Compliance

Manufacturing excellence forms the foundation of this electrical insulation tape's reliable performance. Each production batch undergoes comprehensive testing protocols that evaluate adhesive strength, temperature resistance, dielectric properties, and dimensional consistency. These rigorous quality control measures ensure that every roll meets the exacting standards required for professional electrical applications and maintains consistency across different production runs.

The manufacturing process incorporates advanced quality management systems that monitor critical parameters throughout production. Raw material inspection, in-process testing, and final product validation work together to identify and eliminate potential quality issues before products reach end users. This systematic approach to quality control results in a product that professionals can depend on for critical applications.

Environmental testing simulates real-world conditions to validate the tape's performance under various stress conditions. These tests include thermal cycling, humidity exposure, chemical resistance evaluation, and mechanical stress testing. The comprehensive testing program ensures that the tape will perform reliably across its intended application range and service life.

Compliance with relevant industry standards ensures that this electrical insulation tape meets the safety and performance requirements established by regulatory bodies and industry organizations. This compliance provides users with confidence that the product is suitable for its intended applications and will not compromise the safety or reliability of electrical installations.

Customization & Branding Options

Understanding that different applications may require specific performance characteristics or branding requirements, comprehensive customization options are available for this electrical insulation tape. Custom adhesive formulations can be developed to meet unique application requirements, such as enhanced chemical resistance, modified temperature ranges, or specialized substrate compatibility. These customization capabilities ensure that the tape can be optimized for specific industry requirements or operating conditions.

Private labeling and custom packaging solutions enable distributors and OEM customers to present the product under their own brand identity. Professional packaging design services can create custom graphics, technical specifications, and branding elements that align with customer requirements and market positioning strategies. This flexibility makes the product suitable for various distribution channels and market segments.

Technical consultation services support customers in developing application-specific solutions that maximize the tape's performance in their particular use cases. This collaborative approach ensures that customers receive products optimized for their specific requirements while benefiting from the manufacturer's expertise in adhesive technology and electrical insulation applications.

Volume customization options accommodate both small specialty runs and large-scale production requirements. Flexible manufacturing capabilities ensure that custom solutions can be delivered efficiently regardless of order size, making advanced insulation technology accessible to customers across various market segments and application requirements.

Packaging & Logistics Support

Professional packaging solutions protect the integrity of this electrical insulation tape throughout the distribution chain while facilitating efficient handling and storage. Each roll is individually wrapped to prevent contamination and adhesive transfer, ensuring that the product reaches end users in optimal condition. The packaging design incorporates clear product identification and technical specifications to facilitate proper product selection and application.

Bulk packaging options optimize shipping efficiency for large-volume orders while maintaining product protection standards. These packaging configurations reduce per-unit shipping costs and minimize packaging waste, supporting both economic and environmental objectives. The robust packaging design ensures that products remain secure during international shipping and handling operations.

Inventory management support helps distributors and large-volume users optimize their stock levels and reduce carrying costs. Flexible shipping schedules accommodate varying demand patterns while ensuring product availability when needed. This logistics support enables customers to maintain lean inventory levels while ensuring adequate supply for critical applications.

International shipping expertise ensures compliance with various regulatory requirements and documentation standards across different markets. This capability facilitates global distribution while minimizing delays and complications associated with cross-border shipments. Comprehensive logistics support enables customers to focus on their core business activities while ensuring reliable product supply.

Why Choose Us

With extensive experience serving international markets across multiple industries, our company has established itself as a trusted metal packaging supplier and OEM tin packaging solutions provider, bringing the same commitment to excellence to our electrical insulation products. Our global collaboration with leading manufacturers and distributors has resulted in deep understanding of diverse market requirements and quality expectations, enabling us to deliver products that consistently meet or exceed customer expectations.

Our multi-industry expertise spans automotive, industrial, marine, and aerospace applications, providing customers with access to specialized knowledge and application support that extends beyond simple product supply. This comprehensive understanding of various industry requirements enables us to recommend optimal solutions and provide technical guidance that maximizes product performance in specific applications.

As a recognized custom tin box supplier, we bring the same attention to detail and quality focus to our electrical insulation tape products, ensuring that customers receive consistent quality regardless of the product category. Our commitment to sustainable practices and premium materials extends across our entire product portfolio, providing customers with reliable, environmentally responsible solutions.

Continuous investment in research and development ensures that our products incorporate the latest advances in adhesive technology and material science. This ongoing innovation commitment keeps our products at the forefront of industry performance standards while anticipating future market needs and requirements.

Conclusion

The Electrical Insulation Tape Heat-resistant Adhesive Single Sided Pressure Sensitive Masking 19mm for Car Cable Harness Wiring represents a professional-grade solution engineered to meet the demanding requirements of modern electrical applications. Its combination of exceptional heat resistance, reliable pressure-sensitive adhesion, and durable construction makes it an indispensable component for automotive, industrial, and specialized electrical applications. The comprehensive quality control processes, customization options, and professional support services ensure that customers receive not just a product, but a complete solution tailored to their specific requirements. This electrical insulation tape delivers the performance, reliability, and value that professionals demand for critical electrical applications across diverse industries and operating environments.

| item | value |

| Adhesive | Acrylic |

| Use | MASKING |

| Place of Origin | China |

| Adhesive Side | Single Sided |

| Material | Flannel |

| Type | Insulation Tape |

| Thickness | 0.3mm |

| Adhesive Type | Pressure Sensitive |

| Feature | Heat-resistant |

| Brand Name | YLW |

| Model Number | YLW-R001 |

| Design Printing | Offer Printing |

| cycle length | 10m |

| paper core | Customizable |

| Printing Handling | Offer printing |

| glue | Acrylic |

well

1. who are we?

We are based in Jiangsu, China, start from 2025,sell to Mid East(30.00%),Southeast Asia(20.00%),Central America(20.00%),North America(15.00%),South Asia(15.00%). There are total about - people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

automotive tape

4. why should you buy from us not from other suppliers?

-

5. what services can we provide?

Accepted Delivery Terms: -;

Accepted Payment Currency: -;

Accepted Payment Type: -;

Language Spoken: English