Introduction

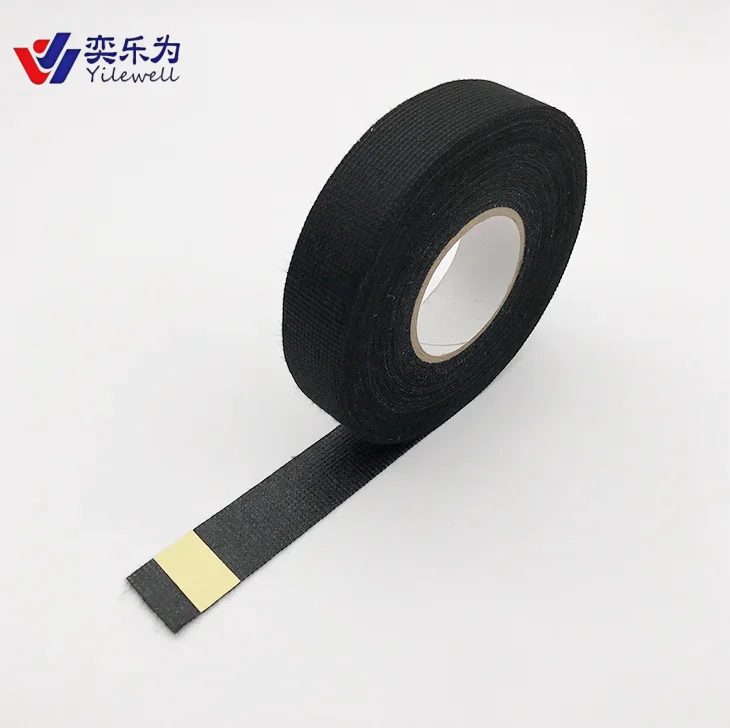

Industrial applications requiring superior thermal protection and secure bonding demand specialized adhesive solutions that can withstand extreme conditions while maintaining consistent performance. The Heat-resistant Single Sided Pressure Sensitive Adhesive Flannel Insulation Tape 19mm Thickness 15m Cycle Length Masking represents a breakthrough in high-temperature masking technology, engineered specifically for demanding manufacturing environments where conventional tapes fail to deliver reliable results.

This advanced flannel-based insulation tape combines exceptional heat resistance with pressure-sensitive adhesive technology, creating a versatile solution for thermal management, surface protection, and precision masking applications. The unique flannel construction provides superior insulation properties while the specialized adhesive formulation ensures reliable bonding across diverse substrates, making it an essential component for industries ranging from automotive manufacturing to aerospace assembly operations.

Product Overview

The Heat-resistant Single Sided Pressure Sensitive Adhesive Flannel Insulation Tape 19mm Thickness 15m Cycle Length Masking features a sophisticated multi-layer construction designed to excel in high-temperature environments. The flannel substrate provides excellent thermal insulation characteristics while maintaining flexibility and conformability to complex surface geometries. This innovative tape solution addresses the critical need for reliable masking and protection during heat-intensive manufacturing processes.

Built with premium-grade materials and advanced adhesive technology, this insulation tape delivers consistent performance across extended temperature ranges. The pressure-sensitive adhesive system ensures immediate bonding upon application while allowing for clean removal without residue formation. The flannel construction not only provides thermal barrier properties but also offers superior tear resistance and dimensional stability under thermal stress conditions.

Manufacturing professionals worldwide rely on this specialized masking tape for applications where standard adhesive products cannot maintain integrity or bonding strength. The extended cycle length format provides excellent value and reduces application downtime, while the precise width specification ensures compatibility with automated application systems and manual installation procedures alike.

Features & Benefits

Advanced Thermal Performance

The exceptional heat resistance characteristics of this flannel insulation tape enable reliable performance in environments where conventional masking materials would degrade or fail completely. The specialized flannel substrate maintains its structural integrity and insulation properties across wide temperature variations, ensuring consistent protection and masking effectiveness throughout demanding thermal cycles.

Superior thermal management capabilities make this tape ideal for applications involving heat treatment processes, welding operations, and high-temperature assembly procedures. The flannel construction creates an effective thermal barrier that protects underlying surfaces while maintaining the flexibility necessary for complex geometric applications.

Pressure-Sensitive Adhesive Technology

The advanced pressure-sensitive adhesive formulation provides immediate bonding strength upon application while maintaining removability characteristics that prevent surface damage during tape removal. This balanced adhesive performance ensures secure positioning during use while enabling clean removal processes that leave no residue or adhesive transfer on treated surfaces.

The single-sided adhesive configuration optimizes the tape for masking applications where controlled adhesion is essential. The adhesive system maintains its bonding characteristics across temperature variations, ensuring reliable masking performance throughout extended thermal exposure periods.

Flannel Substrate Advantages

The flannel construction provides unique benefits including superior insulation properties, excellent conformability, and enhanced tear resistance compared to traditional tape substrates. The textile-based structure creates effective thermal barriers while maintaining the flexibility required for application on curved surfaces and complex geometries.

This specialized substrate material also offers excellent chemical resistance and dimensional stability, ensuring consistent performance characteristics throughout the tape's service life. The flannel construction resists degradation from exposure to industrial solvents and cleaning agents commonly encountered in manufacturing environments.

Applications & Use Cases

Industrial manufacturing operations across diverse sectors utilize the Heat-resistant Single Sided Pressure Sensitive Adhesive Flannel Insulation Tape 19mm Thickness 15m Cycle Length Masking for critical thermal management and surface protection applications. Automotive manufacturing facilities employ this specialized tape during paint curing processes, engine assembly operations, and exhaust system fabrication where extreme temperatures demand reliable masking solutions.

Aerospace manufacturing applications benefit from the tape's exceptional thermal performance during composite curing processes, engine component assembly, and heat treatment operations. The flannel insulation properties provide essential thermal barriers while the pressure-sensitive adhesive ensures secure positioning throughout complex manufacturing sequences.

Electronics manufacturing and semiconductor assembly operations rely on this tape for thermal management during soldering processes, component mounting procedures, and circuit board protection applications. The precise masking capabilities enable accurate component placement while providing thermal insulation that prevents heat damage to sensitive electronic elements.

Metalworking and fabrication industries utilize this insulation tape for welding masking, heat treatment protection, and surface preparation applications. The flannel construction provides effective thermal barriers during metal processing operations while maintaining the flexibility necessary for complex part geometries and multi-stage manufacturing processes.

Glass manufacturing and ceramic processing applications benefit from the tape's ability to provide reliable masking during high-temperature forming and finishing operations. The thermal insulation properties protect adjacent surfaces while the adhesive system maintains secure bonding throughout extended thermal exposure cycles.

Quality Control & Compliance

Rigorous quality assurance protocols ensure that every production batch of this Heat-resistant Single Sided Pressure Sensitive Adhesive Flannel Insulation Tape meets stringent performance standards for thermal resistance, adhesive strength, and dimensional consistency. Advanced testing procedures validate thermal performance characteristics across temperature ranges while confirming adhesive integrity and removability properties.

Manufacturing processes incorporate multiple quality checkpoints that monitor flannel substrate quality, adhesive application uniformity, and final product specifications. These comprehensive quality control measures ensure consistent performance characteristics and reliable application results for demanding industrial environments.

International quality standards guide production processes and material selection, ensuring compatibility with global manufacturing requirements and regulatory compliance standards. Regular quality audits and performance testing protocols maintain product consistency while supporting continuous improvement initiatives that enhance performance characteristics and application reliability.

Environmental compliance considerations influence material selection and manufacturing processes, supporting sustainable production practices while maintaining the exceptional performance characteristics required for industrial applications. Quality documentation systems provide comprehensive traceability and performance verification data for critical applications requiring detailed material specifications.

Customization & Branding Options

Comprehensive customization capabilities enable adaptation of this flannel insulation tape to specific application requirements and performance criteria. Custom formulation options allow for optimization of thermal resistance characteristics, adhesive properties, and substrate specifications to match unique industrial applications and environmental conditions.

Specialized packaging configurations support diverse distribution requirements and application preferences, including custom roll lengths, packaging formats, and labeling specifications. These customization options enable integration with existing inventory management systems while supporting automated application equipment and manual installation procedures.

Private labeling and branding services provide opportunities for distributors and industrial suppliers to develop customized product offerings that meet specific market requirements. Custom packaging design and specification documentation support brand development initiatives while maintaining the exceptional performance characteristics of the base product.

Technical consultation services assist customers in optimizing tape specifications for specific applications, ensuring optimal performance characteristics and cost-effectiveness for demanding industrial environments. These collaborative development processes enable creation of specialized solutions that address unique application challenges and performance requirements.

Packaging & Logistics Support

Professional packaging systems protect product integrity during transportation and storage while supporting efficient inventory management and distribution operations. Specialized packaging materials and configurations ensure that the Heat-resistant Single Sided Pressure Sensitive Adhesive Flannel Insulation Tape maintains its performance characteristics throughout the supply chain.

Comprehensive logistics support includes coordination with international shipping providers, customs documentation assistance, and delivery tracking services that ensure reliable product availability for global customers. These logistics capabilities support just-in-time inventory strategies while minimizing supply chain disruptions for critical manufacturing operations.

Inventory management services provide flexible ordering options and delivery scheduling that accommodate varying demand patterns and production requirements. Advanced inventory tracking systems enable proactive supply chain management while supporting cost optimization initiatives for large-volume applications.

Technical documentation and product specification sheets accompany shipments to ensure proper handling, storage, and application procedures. These comprehensive support materials enable effective product utilization while supporting quality control and performance validation requirements in demanding industrial environments.

Why Choose Us

Our extensive experience in developing specialized adhesive solutions for demanding industrial applications spans decades of collaboration with global manufacturers across diverse sectors. This deep industry expertise enables us to understand the unique challenges faced by modern manufacturing operations while developing innovative products that address specific performance requirements and environmental conditions.

As a recognized custom tin box supplier and OEM tin packaging solutions provider, our company has established a reputation for excellence in material science and manufacturing innovation. Our multi-industry expertise encompasses automotive, aerospace, electronics, and industrial manufacturing sectors, enabling us to develop specialized solutions that meet the most demanding application requirements.

Advanced research and development capabilities drive continuous innovation in adhesive technology and substrate materials, ensuring that our products remain at the forefront of industry performance standards. Our global collaboration network enables rapid response to emerging market needs while supporting the development of next-generation solutions for evolving industrial applications.

International quality certifications and compliance standards validate our commitment to excellence while supporting global distribution and application requirements. Our comprehensive technical support services provide ongoing assistance throughout the product lifecycle, ensuring optimal performance and cost-effectiveness for critical manufacturing operations worldwide.

Conclusion

The Heat-resistant Single Sided Pressure Sensitive Adhesive Flannel Insulation Tape 19mm Thickness 15m Cycle Length Masking represents a significant advancement in high-temperature masking technology, delivering exceptional thermal performance and reliable adhesive characteristics for demanding industrial applications. The unique combination of flannel substrate properties and advanced pressure-sensitive adhesive technology creates a versatile solution that addresses the critical requirements of modern manufacturing operations across diverse industry sectors. This specialized tape solution provides manufacturers with the confidence and reliability necessary for precision masking applications in extreme thermal environments, ensuring consistent results and superior surface protection throughout complex manufacturing processes.

| item | value |

| Adhesive | Acrylic |

| Use | MASKING |

| Place of Origin | China |

| Adhesive Side | Single Sided |

| Material | Flannel |

| Type | Insulation Tape |

| Thickness | 0.3mm |

| Adhesive Type | Pressure Sensitive |

| Feature | Heat-resistant |

| Brand Name | YLW |

| Model Number | YLW-R001 |

| Design Printing | Offer Printing |

| cycle length | 10m |

| paper core | Customizable |

| Printing Handling | Offer printing |

| glue | Acrylic |

well

1. who are we?

We are based in Jiangsu, China, start from 2025,sell to Mid East(30.00%),Southeast Asia(20.00%),Central America(20.00%),North America(15.00%),South Asia(15.00%). There are total about - people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

automotive tape

4. why should you buy from us not from other suppliers?

-

5. what services can we provide?

Accepted Delivery Terms: -;

Accepted Payment Currency: -;

Accepted Payment Type: -;

Language Spoken: English