Introduction

In the demanding world of automotive and industrial applications, reliable cable management solutions are essential for maintaining operational efficiency and safety standards. The High Temp Wire Harness Tape-Self-Adhesive Fabric Adhesive Sticker Acrylic Adhesive for Automotive Engine Wrap Electrical Cable represents a breakthrough in high-performance adhesive technology, specifically engineered to withstand extreme thermal conditions while providing superior bonding strength. This innovative fabric-based adhesive solution addresses the critical need for durable wire harness protection in environments where conventional tapes fail to deliver consistent performance.

Modern automotive and industrial systems operate under increasingly challenging conditions, requiring cable management materials that can endure prolonged exposure to elevated temperatures, mechanical stress, and chemical exposure. This specialized adhesive tape combines advanced acrylic adhesive formulation with robust fabric backing to create a versatile solution that meets the stringent requirements of professional installers, maintenance teams, and manufacturing operations worldwide.

Product Overview

The High Temp Wire Harness Tape-Self-Adhesive Fabric Adhesive Sticker Acrylic Adhesive for Automotive Engine Wrap Electrical Cable features a sophisticated multi-layer construction designed to deliver exceptional performance in high-temperature environments. The fabric backing provides mechanical strength and conformability, while the specialized acrylic adhesive system ensures reliable bonding to various substrates including metal, plastic, and rubber surfaces commonly found in automotive and industrial applications.

This premium adhesive solution incorporates advanced polymer chemistry to maintain its bonding properties even when subjected to thermal cycling, vibration, and exposure to automotive fluids. The self-adhesive design eliminates the need for additional bonding agents or complex installation procedures, making it an ideal choice for both production line applications and field maintenance operations. The fabric construction allows for easy handling and precise application while providing excellent tear resistance and dimensional stability under stress.

Features & Benefits

Superior Thermal Performance

The advanced acrylic adhesive formulation maintains its bonding strength and flexibility across an extensive temperature range, making this tape suitable for engine compartment applications where conventional adhesives deteriorate rapidly. The thermal stability ensures long-term reliability in automotive engine wrapping applications, where consistent performance is critical for maintaining electrical system integrity and preventing costly failures.

Enhanced Durability and Longevity

The robust fabric backing provides exceptional resistance to abrasion, punctures, and mechanical stress, extending the service life of wire harness installations. This durability translates to reduced maintenance requirements and lower total cost of ownership for fleet operators and industrial facilities. The material's resistance to aging and environmental degradation ensures consistent performance throughout its operational lifespan.

Versatile Application Compatibility

The self-adhesive fabric design conforms easily to irregular surfaces and complex geometries, making it suitable for a wide range of cable bundling and protection applications. The tape's flexibility allows it to accommodate thermal expansion and contraction without losing adhesion or developing stress concentrations that could compromise electrical connections or cable integrity.

Applications & Use Cases

The High Temp Wire Harness Tape-Self-Adhesive Fabric Adhesive Sticker Acrylic Adhesive for Automotive Engine Wrap Electrical Cable serves diverse applications across multiple industries where reliable cable management is essential. In automotive manufacturing and aftermarket installations, this tape provides essential protection for wire harnesses in engine compartments, exhaust system proximity, and other high-temperature zones where electrical components require shielding from thermal stress.

Industrial machinery and equipment benefit significantly from this specialized adhesive solution, particularly in applications involving motors, generators, heating systems, and processing equipment where electrical cables must operate reliably in elevated temperature environments. The tape's chemical resistance makes it suitable for use in manufacturing facilities where exposure to solvents, oils, and cleaning agents is common.

Aerospace and marine applications represent additional markets where this high-performance tape delivers value through its ability to maintain bonding strength under extreme environmental conditions. The material's resistance to moisture, salt spray, and temperature fluctuations makes it ideal for protecting critical electrical systems in demanding operational environments where failure is not an option.

Quality Control & Compliance

Manufacturing excellence forms the foundation of this high-temperature wire harness tape, with comprehensive quality control processes ensuring consistent performance and reliability. Each production batch undergoes rigorous testing to verify adhesive strength, thermal stability, and dimensional accuracy, guaranteeing that customers receive products that meet the demanding requirements of professional automotive and industrial applications.

The production facility maintains strict adherence to international quality standards, implementing advanced testing protocols that evaluate material properties under simulated operational conditions. This commitment to quality extends throughout the manufacturing process, from raw material selection to final packaging, ensuring that every roll of tape meets the exacting standards required for critical cable management applications.

Environmental compliance represents another critical aspect of the manufacturing process, with formulations designed to meet regulatory requirements while minimizing environmental impact. The company's dedication to sustainable manufacturing practices includes the use of environmentally responsible materials and processes that support customers' own sustainability initiatives.

Customization & Branding Options

Recognition of diverse customer requirements drives the availability of customization options for the High Temp Wire Harness Tape-Self-Adhesive Fabric Adhesive Sticker Acrylic Adhesive for Automotive Engine Wrap Electrical Cable. Custom width configurations enable optimization for specific application requirements, while color options support organization systems and brand identification needs in professional installations.

Private labeling services accommodate distributors and OEM customers who require branded packaging solutions that align with their corporate identity and market positioning. The flexibility of the manufacturing process allows for the development of specialized formulations tailored to unique application requirements, ensuring that customers receive products optimized for their specific operational conditions.

Technical consultation services support customers in selecting the optimal tape configuration for their applications, with experienced engineers providing guidance on installation techniques, performance optimization, and integration with existing cable management systems. This collaborative approach ensures that customers achieve maximum value from their adhesive tape investment.

Packaging & Logistics Support

Efficient packaging solutions protect the integrity of the High Temp Wire Harness Tape-Self-Adhesive Fabric Adhesive Sticker Acrylic Adhesive for Automotive Engine Wrap Electrical Cable throughout the distribution process while optimizing storage and handling efficiency. Professional-grade packaging maintains the tape's adhesive properties and prevents contamination during transit, ensuring that customers receive products in optimal condition.

Flexible packaging options accommodate various order quantities and distribution requirements, from individual rolls for specialized applications to bulk packaging for high-volume users. The packaging design facilitates easy identification and inventory management, supporting efficient warehouse operations and reducing handling time for distributors and end users.

Global logistics capabilities ensure reliable product availability across international markets, with established distribution networks supporting timely delivery to customers worldwide. The company's logistics expertise includes knowledge of international shipping requirements and documentation, facilitating smooth cross-border transactions for international customers and distributors.

Why Choose Us

With over two decades of experience in developing specialized adhesive solutions for demanding industrial applications, our company has established itself as a trusted partner for customers requiring high-performance cable management products. Our international market presence spans multiple continents, with distribution networks serving automotive manufacturers, industrial equipment suppliers, and maintenance professionals who depend on reliable adhesive solutions for critical applications.

Our commitment to innovation drives continuous improvement in product formulations and manufacturing processes, ensuring that customers benefit from the latest advances in adhesive technology. The company's multi-industry expertise enables us to understand the unique challenges faced by different market segments and develop solutions that address specific application requirements effectively.

As a recognized supplier in the global adhesive market, we maintain strategic partnerships with raw material suppliers and technology providers that enhance our ability to deliver consistent quality and performance. Our technical support capabilities include application engineering assistance and performance optimization guidance that helps customers achieve optimal results from their adhesive tape investments.

Conclusion

The High Temp Wire Harness Tape-Self-Adhesive Fabric Adhesive Sticker Acrylic Adhesive for Automotive Engine Wrap Electrical Cable represents a comprehensive solution for demanding cable management applications where thermal performance, durability, and reliability are essential. Its advanced acrylic adhesive system, robust fabric backing, and exceptional temperature resistance make it an ideal choice for automotive, industrial, and specialized applications where conventional tapes cannot deliver adequate performance. The combination of superior technical properties, customization flexibility, and comprehensive support services positions this product as a valuable asset for professionals seeking reliable cable management solutions that can withstand the challenges of modern operational environments while delivering long-term value and performance consistency.

| item | value |

| Adhesive | Acrylic |

| Use | MASKING |

| Place of Origin | China |

| Adhesive Side | Single Sided |

| Material | Cloth |

| Type | Adhesive Sticker |

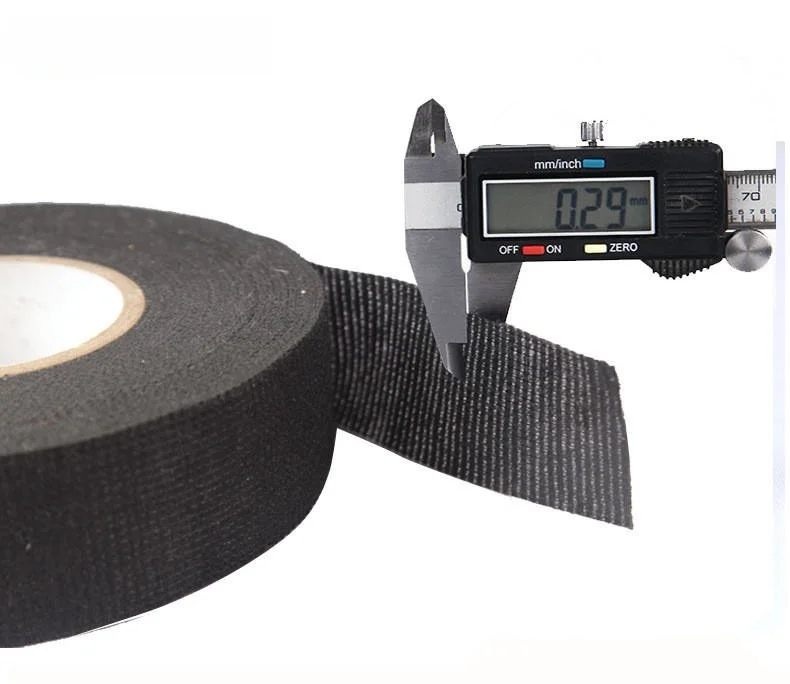

| Thickness | 0.26mm |

| Adhesive Type | Pressure Sensitive |

| Feature | Heat-resistant |

| Brand Name | YLW |

| Model Number | YLW-- B005 |

| Design Printing | No printing |

| cycle length | 25m |

| paper core | No paper core. |

| Printing Handling | No printing |

| glue | Acrylic |

well

1. who are we?

We are based in Jiangsu, China, start from 2025,sell to Mid East(30.00%),Southeast Asia(20.00%),Central America(20.00%),North America(15.00%),South Asia(15.00%). There are total about - people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

automotive tape

4. why should you buy from us not from other suppliers?

-

5. what services can we provide?

Accepted Delivery Terms: -;

Accepted Payment Currency: -;

Accepted Payment Type: -;

Language Spoken: English