Introduction

In today's demanding automotive industry, protecting electrical wiring systems from extreme temperatures and potential fire hazards has become paramount. The High-Temperature Flame-Retardant Automotive Flannel Single Sided PU Adhesive 10m Wiring Harness Tape for Wire Harness Protection represents a cutting-edge solution designed specifically for modern vehicle applications. This specialized tape combines advanced flannel construction with polyurethane adhesive technology to deliver exceptional protection against heat, flames, and mechanical stress. As automotive systems become increasingly complex and operate under more challenging conditions, this protective tape ensures reliable performance while maintaining the integrity of critical electrical connections.

Product Overview

This premium automotive protection tape features a sophisticated flannel backing material that provides excellent thermal insulation properties while maintaining flexibility during installation. The single-sided polyurethane adhesive system ensures secure bonding to various wire harness surfaces without leaving residue upon removal. The tape's construction incorporates flame-retardant compounds that meet stringent automotive safety standards, making it an ideal choice for protecting wiring harnesses in engine compartments, exhaust systems, and other high-temperature environments.

The flannel substrate offers superior conformability around irregular shapes and tight bends commonly found in automotive wiring applications. Unlike traditional cloth tapes, this specialized product maintains its protective properties even when exposed to automotive fluids, vibrations, and thermal cycling. The polyurethane adhesive provides excellent adhesion to metal, plastic, and rubber surfaces while remaining stable across a wide temperature range.

Features & Benefits

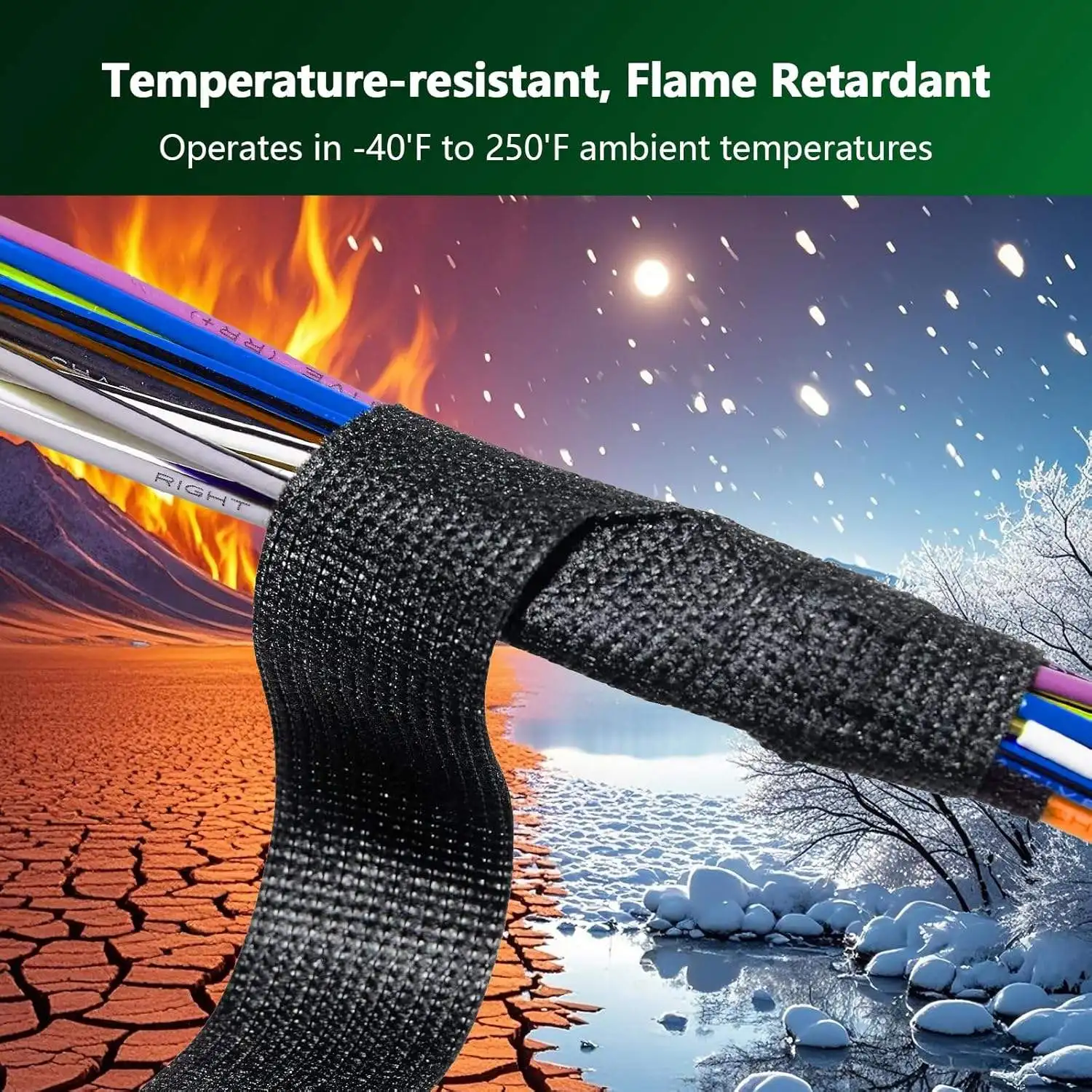

Advanced Thermal Protection

The High-Temperature Flame-Retardant Automotive Flannel Single Sided PU Adhesive 10m Wiring Harness Tape for Wire Harness Protection delivers exceptional thermal barrier performance. The flannel construction creates an insulating layer that prevents heat transfer from engine components to sensitive wiring. This thermal protection extends the service life of electrical systems by preventing premature degradation of wire insulation and connector materials.

Superior Flame Retardancy

Engineered with advanced flame-retardant additives, this protective tape self-extinguishes when exposed to ignition sources, preventing fire propagation along wire harnesses. The flame-retardant properties remain stable throughout the product's service life, ensuring consistent protection even after extended exposure to harsh automotive environments. This critical safety feature helps prevent electrical fires that could compromise vehicle safety and reliability.

Exceptional Adhesive Performance

The single-sided polyurethane adhesive system provides reliable bonding strength while maintaining removability for maintenance access. The adhesive remains tacky across temperature extremes and resists degradation from automotive chemicals, oils, and cleaning solvents. This ensures long-term installation integrity without compromising serviceability during routine maintenance procedures.

Applications & Use Cases

The High-Temperature Flame-Retardant Automotive Flannel Single Sided PU Adhesive 10m Wiring Harness Tape for Wire Harness Protection finds extensive application across various automotive systems. Engine bay installations benefit from the tape's ability to protect main wiring harnesses from radiant heat generated by exhaust manifolds, turbochargers, and engine blocks. The tape's conformability makes it ideal for wrapping complex harness routing around suspension components and through firewall penetrations.

Commercial vehicle applications particularly benefit from this tape's robust construction, as heavy-duty trucks and construction equipment operate in extremely demanding environments. The tape provides essential protection for trailer electrical connections, hydraulic system wiring, and auxiliary equipment harnesses. Marine automotive applications also utilize this tape for protecting electrical systems in boats and recreational vehicles where moisture resistance combines with thermal protection requirements.

Electric and hybrid vehicle manufacturers increasingly specify this type of protective tape for high-voltage wiring systems. The flame-retardant properties provide additional safety margins around battery pack connections and charging system components. The tape's electrical insulation properties complement its thermal protection, making it suitable for sensitive electronic control module connections throughout modern vehicles.

Quality Control & Compliance

Manufacturing of this specialized automotive tape follows rigorous quality control protocols to ensure consistent performance across production batches. Each roll undergoes comprehensive testing for adhesive strength, flame retardancy, thermal stability, and dimensional accuracy. The production facility maintains certified quality management systems that align with international automotive industry standards, ensuring product reliability for critical vehicle applications.

Compliance with automotive industry specifications encompasses flame spread testing, thermal aging protocols, and chemical resistance verification. The tape meets stringent requirements for automotive interior materials while providing enhanced protection capabilities. Regular third-party testing validates ongoing compliance with evolving safety standards and environmental regulations affecting automotive component materials.

Environmental compliance includes verification of restricted substance content and recyclability characteristics. The manufacturing process incorporates sustainable practices while maintaining the high-performance characteristics required for automotive applications. Quality documentation accompanies each shipment, providing traceability and compliance verification for automotive assembly operations.

Customization & Branding Options

Understanding the diverse requirements of automotive manufacturers and aftermarket suppliers, customization options extend beyond standard specifications. Width variations accommodate different harness sizes and installation requirements, while custom lengths provide packaging flexibility for specific production needs. Color customization enables integration with existing wire harness identification systems and maintenance protocols.

Private labeling services support brand development for distributors and specialty automotive suppliers. Custom packaging options include branded dispensers, protective overwraps, and application-specific documentation. Technical data sheets can be customized to highlight specific performance characteristics relevant to particular automotive applications or regional compliance requirements.

Engineering support services assist with product specification development for unique automotive applications. This collaborative approach ensures optimal tape selection for specific thermal, chemical, and mechanical requirements encountered in specialized vehicle designs. Custom testing protocols can be developed to validate performance in application-specific environments before full-scale implementation.

Packaging & Logistics Support

Professional packaging solutions protect product integrity during international shipping while optimizing logistics efficiency. Each roll receives protective wrapping that prevents contamination and physical damage during transit. Packaging configurations accommodate various order quantities while maintaining product quality from manufacturing through end-use application.

Logistics support includes flexible shipping options that align with automotive production schedules and inventory management requirements. Consolidated shipping capabilities reduce transportation costs for larger orders while maintaining delivery reliability. Documentation packages include material safety data sheets, compliance certificates, and application guidelines in multiple languages to support international distribution.

Inventory management services help automotive suppliers maintain optimal stock levels while minimizing carrying costs. Scheduled delivery programs align with production requirements, ensuring material availability without excessive inventory investment. Custom packaging configurations support just-in-time manufacturing processes common in modern automotive assembly operations.

Why Choose Us

With extensive experience serving the global automotive industry, our company has established a reputation for delivering innovative protective solutions that meet the evolving demands of modern vehicle manufacturing. Our international market presence spans multiple continents, enabling us to support automotive manufacturers and suppliers with consistent product quality and reliable supply chain management. This global reach ensures local support while maintaining unified quality standards across all markets.

As a recognized metal packaging manufacturer, our expertise extends beyond automotive tapes to comprehensive protective solutions for various industries. Our position as a custom tin box supplier and provider of OEM tin packaging solutions demonstrates our commitment to innovative material applications and custom engineering capabilities. This diverse experience as a metal packaging supplier enhances our understanding of protective material requirements across multiple demanding applications.

Our multi-industry expertise enables cross-pollination of innovative technologies, bringing advanced materials and manufacturing techniques from aerospace, electronics, and industrial applications to automotive solutions. Collaboration with global partners ensures access to cutting-edge materials and manufacturing processes that keep our products at the forefront of automotive protection technology. This comprehensive approach delivers solutions that exceed standard performance expectations while maintaining cost-effectiveness for volume automotive applications.

Conclusion

The High-Temperature Flame-Retardant Automotive Flannel Single Sided PU Adhesive 10m Wiring Harness Tape for Wire Harness Protection represents a premium solution for protecting critical automotive electrical systems. Its combination of advanced flannel construction, flame-retardant properties, and reliable polyurethane adhesive technology delivers comprehensive protection against thermal, chemical, and mechanical challenges encountered in modern vehicles. The tape's versatility across diverse automotive applications, from traditional internal combustion engines to advanced electric powertrains, makes it an essential component for ensuring electrical system reliability and safety. With rigorous quality control, extensive customization capabilities, and comprehensive logistics support, this specialized tape provides automotive manufacturers and suppliers with a dependable solution for protecting valuable electrical assets while maintaining operational efficiency and regulatory compliance.

| item | value |

| Adhesive | Acrylic |

| Use | MASKING |

| Place of Origin | China |

| Adhesive Side | Single Sided |

| Material | Flannel |

| Type | Insulation Tape |

| Thickness | 0.3mm |

| Adhesive Type | Pressure Sensitive |

| Feature | Heat-resistant |

| Brand Name | YLW |

| Model Number | YLW-R001 |

| Design Printing | Offer Printing |

| cycle length | 10m |

| paper core | Customizable |

| Printing Handling | Offer printing |

| glue | Acrylic |

well

1. who are we?

We are based in Jiangsu, China, start from 2025,sell to Mid East(30.00%),Southeast Asia(20.00%),Central America(20.00%),North America(15.00%),South Asia(15.00%). There are total about - people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

automotive tape

4. why should you buy from us not from other suppliers?

-

5. what services can we provide?

Accepted Delivery Terms: -;

Accepted Payment Currency: -;

Accepted Payment Type: -;

Language Spoken: English