Introduction

In today's demanding automotive and industrial environments, professionals require reliable adhesive solutions that can withstand extreme conditions while maintaining superior performance. The High-Temperature Pressure Sensitive Single Sided Flannelette Tape Automotive Masking Wire Harness Wrapping Heat-Resistant represents a breakthrough in specialized tape technology, engineered specifically for applications where conventional adhesive products fail to deliver consistent results. This advanced textile-based tape combines the durability of synthetic flannelette backing with high-performance pressure-sensitive adhesive systems, creating an optimal solution for automotive masking, wire harness protection, and heat-resistant wrapping applications across multiple industries.

Understanding the critical importance of temperature stability and adhesive integrity in professional applications, this specialized tape has been developed to meet the stringent requirements of automotive manufacturing, electrical installations, and industrial processes. The unique flannelette construction provides excellent conformability while maintaining structural integrity under thermal stress, making it an indispensable tool for quality-conscious professionals and manufacturers worldwide.

Product Overview

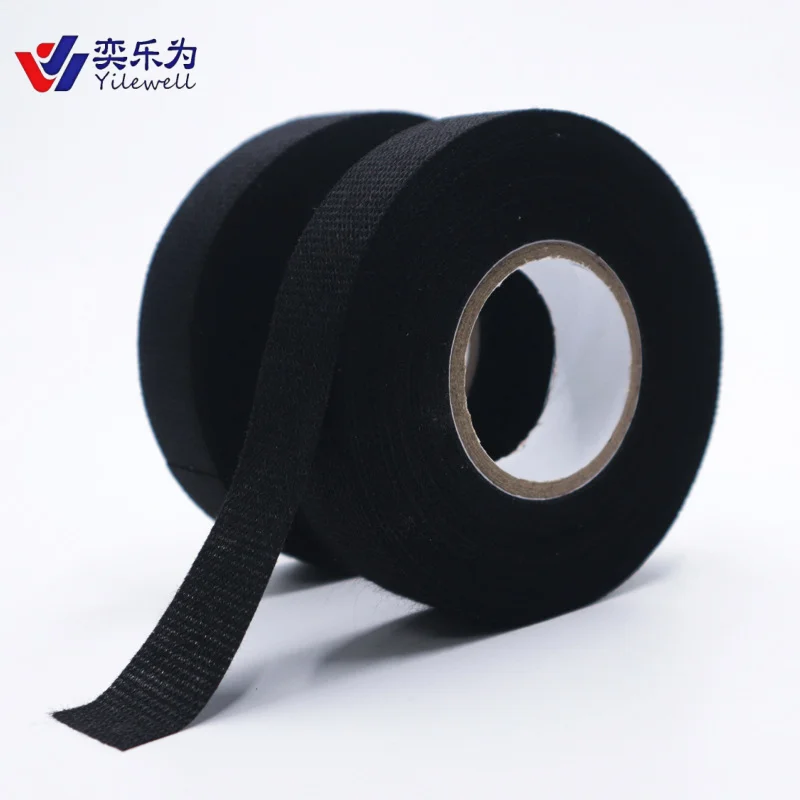

The High-Temperature Pressure Sensitive Single Sided Flannelette Tape Automotive Masking Wire Harness Wrapping Heat-Resistant features a sophisticated construction that combines textile engineering with advanced adhesive chemistry. The flannelette backing material provides exceptional tear resistance and conformability, allowing the tape to adapt seamlessly to irregular surfaces and complex geometries commonly encountered in automotive and industrial applications.

This professional-grade tape utilizes a single-sided adhesive configuration that ensures reliable bonding while facilitating clean removal when temporary applications are required. The pressure-sensitive adhesive system has been specifically formulated to maintain its bonding strength across a wide temperature range, making it particularly suitable for environments where thermal cycling and elevated temperatures are common factors. The tape's heat-resistant properties make it an ideal choice for applications near engines, exhaust systems, and other heat-generating components where standard tapes would fail or degrade.

The flannelette substrate offers unique advantages in terms of handling and application, providing a textile feel that allows for precise placement and repositioning during installation. This characteristic is particularly valuable in wire harness wrapping applications where multiple adjustments may be necessary to achieve optimal coverage and protection.

Features & Benefits

Advanced Thermal Performance

The exceptional heat-resistant capabilities of this specialized tape make it uniquely suited for high-temperature environments where conventional adhesive products would experience adhesive failure or substrate degradation. The carefully selected flannelette backing material maintains its structural integrity and dimensional stability even when exposed to elevated temperatures, ensuring consistent performance throughout the service life of the application.

Superior Conformability and Flexibility

The textile nature of the flannelette backing provides outstanding conformability, allowing the tape to follow complex contours and irregular surfaces without creating air pockets or adhesive voids. This flexibility is particularly beneficial in automotive masking applications where precise edge definition and complete surface coverage are essential for achieving professional results. The tape's ability to stretch and conform without losing adhesive contact ensures reliable performance across a wide range of application scenarios.

Reliable Pressure-Sensitive Adhesion

The single-sided pressure-sensitive adhesive system has been engineered to provide immediate bonding upon application while maintaining removability characteristics when required. This balance between adhesive strength and removability makes the tape versatile for both permanent and temporary applications, providing professionals with flexibility in their application strategies. The adhesive chemistry resists cold flow and maintains its bonding characteristics over extended periods, ensuring long-term reliability in demanding service environments.

Enhanced Durability and Tear Resistance

The robust flannelette construction offers excellent tear resistance and mechanical durability, reducing the likelihood of premature failure during handling and service. This durability translates into cost savings and improved reliability, particularly important in automotive and industrial applications where tape failure can result in significant downtime or rework costs.

Applications & Use Cases

The versatility of the High-Temperature Pressure Sensitive Single Sided Flannelette Tape Automotive Masking Wire Harness Wrapping Heat-Resistant makes it suitable for numerous applications across automotive, aerospace, and industrial sectors. In automotive manufacturing and repair operations, this tape excels in masking applications where paint booths and high-temperature curing processes are involved, providing clean paint lines and protecting sensitive components from overspray and thermal exposure.

Wire harness wrapping represents another critical application area where this specialized tape demonstrates superior performance. The tape's conformability allows it to wrap tightly around wire bundles of varying sizes, providing protection against abrasion, moisture, and thermal damage. The flannelette backing offers additional benefits by providing a non-slip surface that helps maintain wire organization and prevents bundle shifting during vehicle operation or industrial processes.

Industrial applications extend to equipment maintenance and repair scenarios where temporary protection or marking is required in high-temperature environments. The tape's heat-resistant properties make it valuable for applications near furnaces, ovens, and other thermal processing equipment where conventional tapes would fail. Additionally, the tape serves as an effective solution for temporary bundling and organization of cables and hoses in industrial installations where heat exposure is a concern.

Electronics and electrical applications benefit from the tape's non-conductive flannelette backing and reliable adhesive performance. The tape can be used for insulating electrical connections, organizing wire runs, and providing strain relief in applications where temperature fluctuations are common. The conformable nature of the flannelette backing allows for neat, professional installations that maintain their appearance and functionality over time.

Quality Control & Compliance

Manufacturing of the High-Temperature Pressure Sensitive Single Sided Flannelette Tape Automotive Masking Wire Harness Wrapping Heat-Resistant follows stringent quality control protocols that ensure consistent performance characteristics across all production batches. The manufacturing process incorporates multiple inspection points where adhesive thickness, backing material integrity, and thermal performance are verified to meet established specifications.

Raw material selection plays a crucial role in maintaining product quality, with both the flannelette backing and pressure-sensitive adhesive systems sourced from qualified suppliers who maintain their own quality management systems. Incoming materials undergo comprehensive testing to verify compliance with performance requirements before being released for production use.

Environmental testing forms an integral part of the quality assurance process, with representative samples subjected to accelerated aging tests, thermal cycling, and adhesive performance evaluations under various environmental conditions. These tests ensure that the tape will maintain its specified performance characteristics throughout its intended service life, providing users with confidence in product reliability.

Documentation and traceability systems maintain complete records of production parameters and quality test results, enabling rapid identification and resolution of any quality issues that may arise. This systematic approach to quality management ensures that each roll of tape meets the high standards expected by professional users in demanding applications.

Customization & Branding Options

Recognizing the diverse needs of professional users and OEM applications, customization options are available for the High-Temperature Pressure Sensitive Single Sided Flannelette Tape Automotive Masking Wire Harness Wrapping Heat-Resistant to meet specific application requirements. Width variations can be provided to accommodate different application needs, from narrow precision work to wide-area coverage applications.

Color customization options allow the tape to be matched to specific aesthetic requirements or coding systems used in various industries. While the standard flannelette backing provides excellent performance characteristics, alternative colors can be produced to meet specific visual identification or branding requirements without compromising the tape's thermal and adhesive performance.

Private labeling and custom packaging options enable distributors and OEM customers to incorporate their own branding while maintaining the superior performance characteristics that define this specialized tape product. Custom packaging configurations can be developed to meet specific distribution requirements or end-user preferences, including bulk packaging for high-volume applications or individual retail packaging for smaller users.

Technical modifications to adhesive characteristics or backing material properties can be evaluated for specific applications where standard product specifications may not fully meet unique requirements. These custom development projects leverage extensive materials science expertise to create tailored solutions while maintaining the fundamental performance advantages that make this tape suitable for demanding applications.

Packaging & Logistics Support

Professional packaging solutions ensure that the High-Temperature Pressure Sensitive Single Sided Flannelette Tape Automotive Masking Wire Harness Wrapping Heat-Resistant reaches end users in optimal condition, ready for immediate use in demanding applications. The packaging design protects the tape from environmental factors that could affect adhesive performance or backing material integrity during storage and transportation.

Moisture barrier packaging prevents humidity exposure that could potentially affect adhesive characteristics, while impact-resistant containers protect against mechanical damage during handling and shipping. The packaging materials themselves are selected for compatibility with the tape product, ensuring that no contamination or adverse chemical reactions can occur during storage periods.

Logistics support encompasses efficient distribution networks that can accommodate both large-volume commercial orders and smaller quantities required by specialized applications. Inventory management systems ensure product availability while maintaining optimal storage conditions that preserve product quality throughout the distribution chain.

Documentation accompanying each shipment provides comprehensive product information, application guidelines, and storage recommendations that enable end users to achieve optimal results from their tape applications. Technical support materials help ensure proper application techniques are employed, maximizing the performance benefits that this specialized tape can provide.

Why Choose Us

With decades of experience in developing specialized adhesive solutions for demanding industrial applications, our company has established a reputation for delivering innovative products that meet the evolving needs of professional users worldwide. Our expertise spans multiple industries, enabling us to understand the unique challenges faced by automotive manufacturers, electrical contractors, and industrial maintenance professionals who rely on high-performance tape products.

As a recognized metal packaging manufacturer and custom tin box supplier, our diversified manufacturing capabilities extend beyond adhesive tapes to encompass comprehensive packaging solutions that serve OEM tin packaging solutions requirements across various industries. This broad manufacturing base provides stability and resources that benefit all product lines, including our specialized tape offerings.

International market presence ensures that customers worldwide have access to consistent product quality and reliable supply chains, regardless of their geographic location. Our global distribution network and local technical support capabilities provide the foundation for successful long-term partnerships with customers who demand excellence in both product performance and service delivery.

Continuous investment in research and development maintains our position at the forefront of adhesive technology innovation, ensuring that our products continue to meet the evolving requirements of modern industrial applications. Our technical team works closely with customers to understand emerging challenges and develop solutions that address real-world application needs.

Conclusion

The High-Temperature Pressure Sensitive Single Sided Flannelette Tape Automotive Masking Wire Harness Wrapping Heat-Resistant represents a significant advancement in specialized adhesive tape technology, combining superior thermal performance with the versatility and reliability demanded by professional applications. Its unique flannelette backing provides exceptional conformability and durability, while the advanced pressure-sensitive adhesive system ensures reliable bonding across a wide range of operating conditions. From automotive masking operations to wire harness protection and industrial applications, this specialized tape delivers consistent performance that professionals can depend upon. The combination of heat resistance, mechanical durability, and application versatility makes this product an invaluable addition to any professional toolkit, providing solutions for challenging applications where conventional tapes simply cannot deliver the required performance. Through careful engineering and rigorous quality control, this tape sets new standards for thermal performance and reliability in demanding professional environments.

| item | value |

| Adhesive | Acrylic |

| Use | MASKING |

| Place of Origin | China |

| Adhesive Side | Single Sided |

| Material | Flannel |

| Type | Insulation Tape |

| Thickness | 0.3mm |

| Adhesive Type | Pressure Sensitive |

| Feature | Heat-resistant |

| Brand Name | YLW |

| Model Number | YLW-R001 |

| Design Printing | Offer Printing |

| cycle length | 10m |

| paper core | Customizable |

| Printing Handling | Offer printing |

| glue | Acrylic |

well

1. who are we?

We are based in Jiangsu, China, start from 2025,sell to Mid East(30.00%),Southeast Asia(20.00%),Central America(20.00%),North America(15.00%),South Asia(15.00%). There are total about - people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

automotive tape

4. why should you buy from us not from other suppliers?

-

5. what services can we provide?

Accepted Delivery Terms: -;

Accepted Payment Currency: -;

Accepted Payment Type: -;

Language Spoken: English