Introduction

In the rapidly evolving automotive industry, reliable wire harness protection has become a critical component for ensuring vehicle safety, performance, and longevity. The Industrial Black Adhesive Fabric Tape for Automotive Wire Harness Binding - PET Loom, Customizable represents a cutting-edge solution designed to meet the stringent demands of modern automotive manufacturing and aftermarket applications. This specialized fabric tape combines advanced PET loom construction with high-performance adhesive technology, delivering exceptional durability and versatility for wire management systems across diverse automotive platforms.

As automotive electrical systems become increasingly complex, the need for superior wire harness binding solutions has intensified. This industrial-grade fabric tape addresses these challenges by providing robust protection against environmental factors while maintaining the flexibility required for dynamic automotive applications. The black coloration offers both aesthetic appeal and practical advantages, including UV resistance and professional appearance in visible installations.

Product Overview

The Industrial Black Adhesive Fabric Tape for Automotive Wire Harness Binding - PET Loom, Customizable utilizes advanced polyethylene terephthalate loom technology to create a superior binding solution for automotive wire management. This innovative construction method produces a fabric tape with exceptional tensile strength, flexibility, and adhesive retention properties that exceed conventional cloth tapes in demanding automotive environments.

The PET loom construction provides inherent resistance to temperature fluctuations, moisture, and chemical exposure commonly encountered in automotive applications. The specialized adhesive system ensures reliable bonding to various wire harness materials while allowing for clean removal when necessary during maintenance or repair operations. This balance between adhesive strength and removability makes the tape ideal for both permanent installations and temporary protective applications during vehicle assembly processes.

The customizable nature of this fabric tape allows manufacturers and automotive professionals to specify exact requirements for width, length, adhesive strength, and packaging configurations. This flexibility ensures optimal compatibility with existing wire harness systems while accommodating unique application requirements across different vehicle types and manufacturing processes.

Features & Benefits

Advanced PET Loom Technology

The sophisticated PET loom construction methodology employed in manufacturing this fabric tape creates a unique fiber structure that combines strength with flexibility. This advanced weaving technique produces consistent thickness and density throughout the tape, ensuring uniform performance characteristics across the entire length. The PET fibers provide excellent resistance to fraying and unraveling, maintaining structural integrity even when subjected to repeated flexing and vibration typical in automotive environments.

Superior Adhesive Performance

The specially formulated adhesive system delivers exceptional bonding strength to various substrates while maintaining conformability around irregular wire bundle shapes. The adhesive remains stable across wide temperature ranges, preventing degradation in extreme hot or cold conditions. This reliability ensures consistent performance throughout the vehicle's operational life, reducing maintenance requirements and improving overall system reliability.

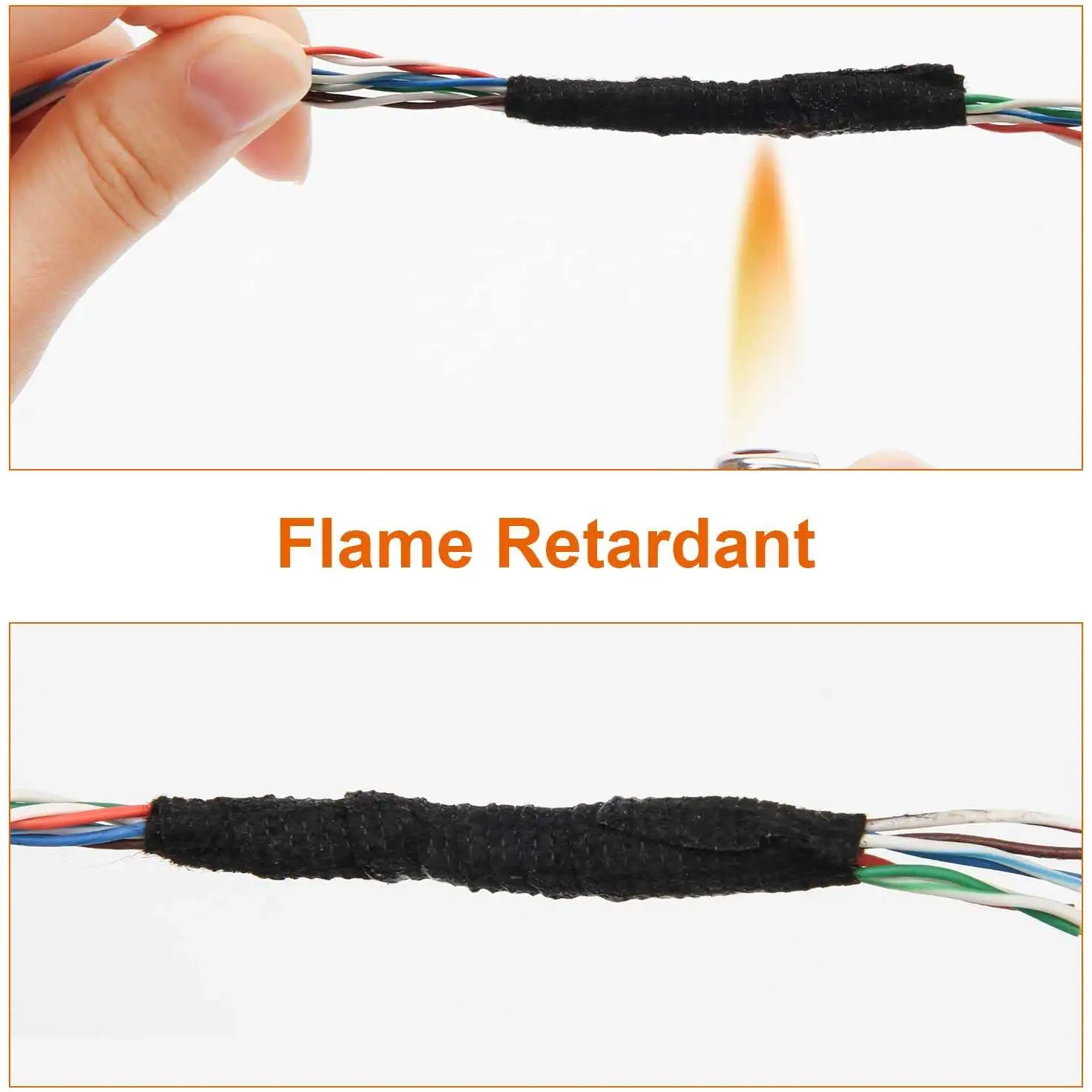

Enhanced Durability Characteristics

The black fabric construction provides inherent UV resistance, preventing degradation from sun exposure in engine bay or exterior applications. The material demonstrates excellent resistance to automotive fluids including oils, coolants, and cleaning solvents, maintaining integrity even in contaminated environments. The fabric's natural breathability helps prevent moisture accumulation beneath the tape, reducing the risk of corrosion in underlying wire components.

The tear-resistant properties of the PET loom construction allow for controlled unwinding and application while preventing accidental tearing during installation. This characteristic is particularly valuable in production environments where consistent application speed and reliability are essential for maintaining manufacturing efficiency.

Applications & Use Cases

The versatility of the Industrial Black Adhesive Fabric Tape for Automotive Wire Harness Binding - PET Loom, Customizable makes it suitable for numerous automotive applications beyond traditional wire harness binding. In engine compartments, the tape provides reliable protection for wiring systems exposed to high temperatures, vibration, and chemical contamination. The fabric construction allows for secure bundling of complex wire assemblies while accommodating thermal expansion and contraction cycles.

Interior applications benefit from the tape's clean appearance and noise-dampening properties. The fabric surface helps reduce vibration-induced noise from wire harnesses, contributing to improved cabin acoustics. The black coloration blends seamlessly with most interior trim materials, providing an unobtrusive appearance in visible installations.

Chassis and undercarriage applications take advantage of the tape's resistance to road salt, moisture, and debris. The robust construction withstands the harsh environment beneath vehicles while maintaining secure wire harness protection. The adhesive system remains effective even when exposed to washing and cleaning operations, ensuring long-term reliability in service environments.

Aftermarket and repair applications benefit from the tape's ease of application and removal characteristics. Technicians can quickly and efficiently bundle replacement wire harnesses or add protective covering to existing installations. The customizable nature allows for precise matching to original equipment specifications, ensuring professional-quality repairs and modifications.

Quality Control & Compliance

Manufacturing of this industrial fabric tape follows rigorous quality control protocols designed to ensure consistent performance and reliability. Each production batch undergoes comprehensive testing to verify adhesive strength, fabric integrity, and dimensional accuracy. The PET loom construction process includes multiple inspection points to identify and eliminate any irregularities that could affect performance in automotive applications.

Environmental compliance represents a key focus in the development and production of this fabric tape. The materials and manufacturing processes meet stringent automotive industry standards for emissions and environmental impact. The recyclable nature of the PET components supports sustainability initiatives while maintaining the performance characteristics required for demanding automotive applications.

The adhesive formulation undergoes extensive testing to ensure compatibility with automotive wire insulation materials and other components commonly found in wire harness assemblies. This testing prevents adverse chemical interactions that could compromise wire performance or safety systems. Temperature cycling tests verify adhesive stability across the full range of automotive operating conditions, from arctic cold starts to high-temperature engine bay environments.

Traceability systems track each production lot from raw material procurement through final packaging, enabling rapid identification and resolution of any quality issues. This comprehensive approach ensures that automotive manufacturers and repair facilities receive consistently reliable products that meet their exacting standards for safety and performance.

Customization & Branding Options

The customizable nature of this fabric tape extends beyond basic dimensional specifications to include comprehensive branding and identification solutions. Custom printing capabilities allow for the addition of part numbers, installation instructions, or company logos directly onto the tape surface. This feature proves particularly valuable for automotive manufacturers seeking to maintain brand consistency throughout their production processes or for aftermarket suppliers requiring clear product identification.

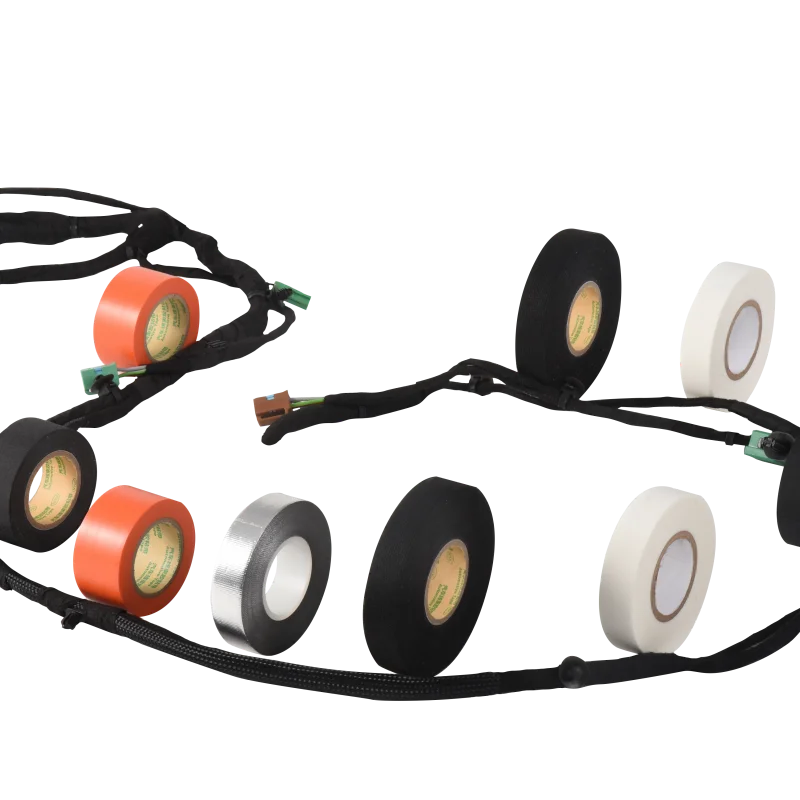

Color customization options expand beyond the standard black configuration to include various automotive-appropriate colors that match specific vehicle interior or engine bay color schemes. This flexibility enables seamless integration with existing design aesthetics while maintaining the functional benefits of the PET loom construction and specialized adhesive system.

Packaging customization accommodates different distribution and application requirements, from bulk rolls for high-volume manufacturing operations to smaller retail packages for aftermarket applications. Custom packaging can include specific product information, installation guidelines, and safety warnings tailored to particular market segments or regulatory requirements.

Technical customization addresses unique application requirements such as enhanced temperature resistance, specialized adhesive formulations for difficult substrates, or modified fabric construction for specific flexibility requirements. These technical adaptations ensure optimal performance in specialized automotive applications while maintaining the core benefits of the standard product design.

Packaging & Logistics Support

Comprehensive packaging solutions protect the integrity of this industrial fabric tape throughout distribution and storage. Protective packaging prevents contamination of adhesive surfaces while maintaining proper environmental conditions to preserve adhesive performance. Climate-controlled storage recommendations ensure that the tape maintains optimal application characteristics regardless of storage duration or environmental conditions.

The packaging design facilitates efficient handling and inventory management in both manufacturing and repair facility environments. Clear labeling systems provide immediate identification of product specifications, lot information, and application guidelines. This organization reduces handling time and minimizes the risk of specification errors during installation processes.

Logistics support extends to global distribution networks that ensure consistent product availability across international markets. Regional distribution centers maintain adequate inventory levels while providing local technical support and application assistance. This distributed approach reduces delivery times while ensuring that regional variations in automotive requirements are properly addressed.

Environmental considerations influence packaging material selection, with recyclable and biodegradable options available where appropriate. This commitment to environmental responsibility aligns with automotive industry sustainability initiatives while maintaining the protective qualities necessary for product integrity during transportation and storage.

Why Choose Us

Our company brings extensive experience in developing specialized adhesive solutions for the global automotive industry, with established partnerships spanning major automotive markets worldwide. This international presence ensures deep understanding of regional requirements, regulatory standards, and application preferences that influence product development and customization strategies.

The technical expertise developed through years of collaboration with leading automotive manufacturers enables us to provide comprehensive support beyond basic product supply. Our engineering teams work closely with customers to develop application-specific solutions that optimize performance while maintaining cost-effectiveness. This collaborative approach has established our reputation as a trusted metal packaging manufacturer and supplier of specialized industrial adhesive products across multiple industry sectors.

Quality assurance systems meet or exceed automotive industry standards, with comprehensive testing protocols that verify performance under real-world conditions. Our commitment to continuous improvement drives ongoing research and development initiatives that anticipate future automotive requirements and technological advances. This forward-thinking approach ensures that our products remain at the forefront of automotive wire harness binding technology.

Customer support services include technical consultation, application assistance, and customization development to address specific requirements. Our global network of technical specialists provides local expertise while maintaining consistency with international quality standards. This combination of global reach and local support creates value for customers regardless of their location or application requirements.

Conclusion

The Industrial Black Adhesive Fabric Tape for Automotive Wire Harness Binding - PET Loom, Customizable represents a superior solution for modern automotive wire management challenges. The advanced PET loom construction combined with specialized adhesive technology delivers exceptional performance, durability, and versatility across diverse automotive applications. The customizable nature of this product ensures optimal compatibility with specific requirements while maintaining the consistent quality and reliability demanded by automotive professionals worldwide. This fabric tape stands as a testament to innovative engineering and manufacturing excellence, providing automotive manufacturers, repair facilities, and aftermarket suppliers with a dependable solution that enhances both performance and efficiency in wire harness applications.

| item | value |

| Adhesive | Acrylic |

| Use | MASKING |

| Place of Origin | China |

| Adhesive Side | Single Sided |

| Material | Flannel |

| Type | Insulation Tape |

| Thickness | 0.3mm |

| Adhesive Type | Pressure Sensitive |

| Feature | Heat-resistant |

| Brand Name | YLW |

| Model Number | YLW-R001 |

| Design Printing | Offer Printing |

| cycle length | 10m |

| paper core | Customizable |

| Printing Handling | Offer printing |

| glue | Acrylic |

well

1. who are we?

We are based in Jiangsu, China, start from 2025,sell to Mid East(30.00%),Southeast Asia(20.00%),Central America(20.00%),North America(15.00%),South Asia(15.00%). There are total about - people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

automotive tape

4. why should you buy from us not from other suppliers?

-

5. what services can we provide?

Accepted Delivery Terms: -;

Accepted Payment Currency: -;

Accepted Payment Type: -;

Language Spoken: English