Introduction

In the demanding world of automotive manufacturing and electrical systems, proper wire harness insulation remains a critical factor determining vehicle safety, performance, and longevity. The TLW-R001 Automotive Wire Harness Insulation Masking Tape Flannel Cloth Heat-Resistant 0.3mm Thickness 10m Cycle Length represents a specialized solution engineered to meet the stringent requirements of modern automotive applications. This professional-grade insulation tape combines advanced flannel cloth construction with exceptional heat resistance properties, delivering reliable protection for complex wire harness assemblies in challenging operating environments.

Designed specifically for automotive electrical systems, this heat-resistant masking tape addresses the growing need for durable, temperature-stable insulation materials that can withstand the harsh conditions found in engine compartments, chassis assemblies, and electronic control modules. The flannel cloth backing provides superior conformability and adhesion characteristics, ensuring consistent performance across diverse installation scenarios while maintaining the electrical integrity essential for modern vehicle operation.

Product Overview

The TLW-R001 Automotive Wire Harness Insulation Masking Tape represents a carefully engineered solution that balances mechanical strength, thermal stability, and electrical insulation properties. Built with a specialized flannel cloth substrate, this tape delivers exceptional conformability that allows it to wrap smoothly around complex wire harness geometries while maintaining consistent thickness throughout the application. The heat-resistant formulation ensures reliable performance in high-temperature automotive environments where traditional insulation materials may fail or degrade over time.

This professional-grade insulation tape incorporates advanced adhesive technology that provides secure bonding without leaving residue or compromising the underlying wire insulation. The flannel cloth construction offers excellent tear resistance and dimensional stability, making it ideal for applications requiring long-term reliability and consistent electrical isolation. The tape's uniform thickness profile ensures predictable installation characteristics and eliminates the variations that can compromise insulation effectiveness in critical automotive electrical systems.

Manufacturing precision extends throughout every aspect of this product, from the carefully controlled flannel substrate weaving to the precise application of heat-resistant adhesive compounds. The result is an insulation tape that meets the demanding performance standards required for automotive wire harness protection while offering the ease of application that installers and technicians depend upon for efficient production processes.

Features & Benefits

Superior Heat Resistance Performance

The exceptional heat resistance characteristics of this automotive insulation tape make it particularly suitable for applications in engine compartments, exhaust system proximity, and other high-temperature zones within vehicles. The specialized material composition maintains its insulation properties and structural integrity even when exposed to the elevated temperatures commonly encountered in automotive environments, ensuring long-term reliability and safety.

Advanced Flannel Cloth Construction

The flannel cloth substrate provides unique advantages in automotive wire harness applications, offering superior flexibility that enables the tape to conform to irregular shapes and tight bend radii without cracking or delaminating. This construction also delivers excellent abrasion resistance, protecting wire harnesses from mechanical damage during installation and throughout the vehicle's operational lifetime.

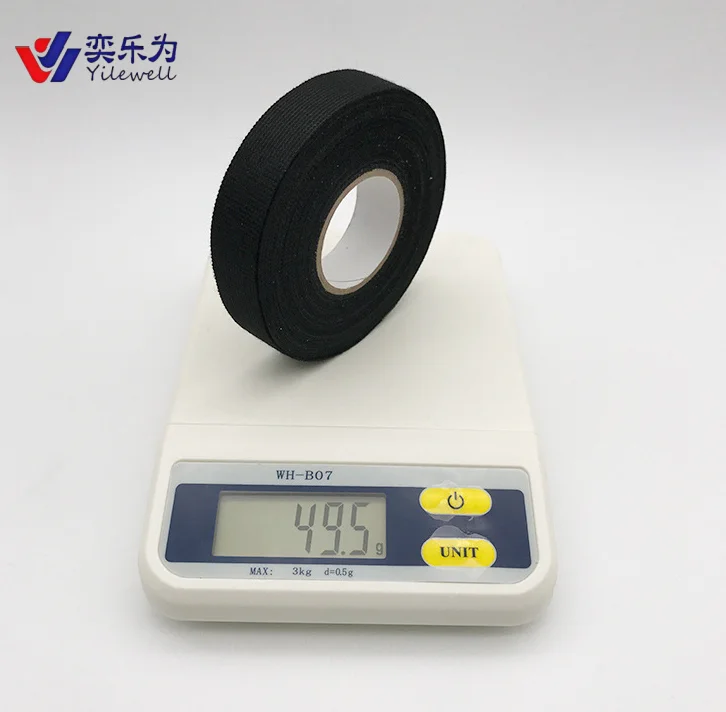

Consistent Thickness Profile

Uniform thickness distribution across the entire tape length ensures predictable insulation characteristics and eliminates the hot spots or weak points that can develop with inferior materials. This consistency is particularly important in automotive applications where electrical safety margins must be maintained across diverse operating conditions and environmental exposures.

Enhanced Adhesion Properties

The specialized adhesive system provides reliable bonding to various wire insulation materials while maintaining removability when required for service or modification. This balanced approach ensures secure installation without the permanent adhesion that can complicate maintenance procedures or component replacement in automotive service applications.

Applications & Use Cases

Automotive wire harness insulation represents the primary application domain for the TLW-R001 tape, where its combination of heat resistance and mechanical durability proves essential for protecting electrical connections in demanding vehicle environments. Engine compartment installations particularly benefit from the tape's ability to maintain insulation integrity despite exposure to high temperatures, vibration, and chemical contaminants commonly found in these areas.

Electronic control module protection represents another critical application where this specialized tape excels, providing reliable insulation for the sensitive wire connections that control modern vehicle systems. The flannel cloth construction offers excellent electromagnetic interference shielding properties while maintaining the flexibility needed for complex routing requirements in confined spaces.

Chassis and underbody wire harness assemblies also benefit significantly from this tape's protective capabilities, particularly in applications where exposure to road salt, moisture, and temperature variations can compromise inferior insulation materials. The heat-resistant formulation ensures consistent performance across the full range of operating conditions encountered in automotive service.

Manufacturing and assembly operations find this tape particularly valuable for temporary masking applications during painting, coating, or welding processes where wire harnesses must be protected from process contamination. The clean removal characteristics prevent damage to delicate wire insulation while ensuring complete protection during manufacturing operations.

Quality Control & Compliance

Stringent quality assurance protocols govern every aspect of manufacturing for the TLW-R001 Automotive Wire Harness Insulation Masking Tape, ensuring consistent performance characteristics that meet the demanding standards required for automotive applications. Advanced testing procedures validate heat resistance properties, adhesion strength, and electrical insulation capabilities before products reach end users, providing confidence in critical safety applications.

Material traceability systems track each production batch through comprehensive quality checkpoints, ensuring that every roll of tape meets established specifications for thickness uniformity, tensile strength, and thermal stability. These rigorous controls are particularly important for automotive applications where component failure can have serious safety implications.

Environmental testing protocols simulate the harsh conditions encountered in automotive service, including temperature cycling, humidity exposure, and chemical resistance evaluation. This comprehensive approach ensures that the tape maintains its protective properties throughout the expected service life of automotive electrical systems.

International automotive industry standards guide the development and validation of this specialized insulation tape, ensuring compatibility with global vehicle manufacturing requirements and regulatory compliance across diverse markets. These standards also facilitate integration with existing automotive quality management systems and supplier qualification processes.

Customization & Branding Options

Recognizing the diverse requirements of automotive manufacturers and electrical system integrators, comprehensive customization capabilities are available for the TLW-R001 insulation tape to meet specific application needs and branding requirements. Custom packaging solutions can incorporate company logos, part numbers, and application instructions to support efficient inventory management and quality control procedures.

Specialized adhesive formulations can be developed for unique application requirements, including enhanced removability for service applications or increased bond strength for permanent installations. These customizations maintain the core heat resistance and mechanical properties while optimizing performance for specific use cases.

Private labeling options allow distributors and system integrators to market this high-performance tape under their own brand identity while maintaining the quality and reliability that automotive applications demand. Custom packaging formats can also be developed to optimize material usage and reduce waste in high-volume manufacturing environments.

Technical documentation customization ensures that product specifications, application guidelines, and safety information align with specific customer requirements and internal quality management systems. This comprehensive approach supports seamless integration into existing automotive manufacturing and service procedures.

Packaging & Logistics Support

Efficient packaging systems protect the TLW-R001 tape during transportation and storage while facilitating easy dispensing and inventory management in automotive manufacturing environments. Moisture-resistant packaging maintains adhesive properties and prevents contamination that could compromise insulation performance in critical applications.

Standardized packaging formats simplify inventory management and reduce handling costs in high-volume automotive applications, while custom packaging solutions can accommodate specific operational requirements or automated dispensing systems. Clear labeling and identification systems ensure proper material selection and traceability throughout the supply chain.

Global logistics capabilities ensure reliable supply chain support for automotive manufacturers and distributors operating across multiple markets, with strategic inventory positioning that minimizes lead times and supports just-in-time manufacturing requirements. Comprehensive documentation packages accompany each shipment to facilitate customs clearance and regulatory compliance.

Environmental considerations guide packaging design choices, with recyclable materials and minimal packaging waste supporting sustainability initiatives common in modern automotive manufacturing. These approaches balance product protection requirements with environmental responsibility while maintaining cost-effectiveness for high-volume applications.

Why Choose Us

With over two decades of experience serving the global automotive industry, our company has established a reputation for delivering innovative insulation solutions that meet the evolving demands of modern vehicle electrical systems. Our extensive international market presence spans major automotive manufacturing regions, providing local support while maintaining consistent quality standards across all markets.

As a recognized metal packaging manufacturer and custom tin box supplier, we understand the importance of precision manufacturing and quality consistency in automotive applications. Our comprehensive OEM tin packaging solutions demonstrate our commitment to meeting exact customer specifications while maintaining the flexibility to adapt to changing market requirements.

Advanced manufacturing capabilities and continuous investment in research and development ensure that our products remain at the forefront of automotive insulation technology. Our metal packaging supplier credentials reflect the same attention to quality and reliability that characterizes our specialized tape products, providing customers with confidence in critical applications.

Collaborative partnerships with automotive manufacturers and electrical system integrators worldwide provide valuable insights into emerging requirements and application challenges. This direct market engagement enables us to anticipate customer needs and develop solutions that address real-world performance requirements while maintaining compatibility with existing manufacturing processes.

Conclusion

The TLW-R001 Automotive Wire Harness Insulation Masking Tape Flannel Cloth Heat-Resistant 0.3mm Thickness 10m Cycle Length represents a sophisticated solution engineered specifically for the demanding requirements of automotive electrical systems. Its combination of superior heat resistance, flexible flannel cloth construction, and reliable adhesion properties makes it an ideal choice for protecting wire harnesses in challenging automotive environments. The tape's consistent performance characteristics, comprehensive quality assurance, and customization capabilities position it as a valuable component in modern automotive manufacturing and service applications. For automotive manufacturers, electrical system integrators, and service professionals seeking reliable insulation solutions, this specialized tape delivers the performance, durability, and quality assurance essential for maintaining electrical system integrity in today's demanding automotive applications.

| item | value |

| Adhesive | Acrylic |

| Use | MASKING |

| Place of Origin | China |

| Adhesive Side | Single Sided |

| Material | Flannel |

| Type | Insulation Tape |

| Thickness | 0.3mm |

| Adhesive Type | Pressure Sensitive |

| Feature | Heat-resistant |

| Brand Name | YLW |

| Model Number | YLW-R001 |

| Design Printing | Offer Printing |

| cycle length | 10m |

| paper core | Customizable |

| Printing Handling | Offer printing |

| glue | Acrylic |

well

1. who are we?

We are based in Jiangsu, China, start from 2025,sell to Mid East(30.00%),Southeast Asia(20.00%),Central America(20.00%),North America(15.00%),South Asia(15.00%). There are total about - people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

automotive tape

4. why should you buy from us not from other suppliers?

-

5. what services can we provide?

Accepted Delivery Terms: -;

Accepted Payment Currency: -;

Accepted Payment Type: -;

Language Spoken: English