Introduction

In the demanding world of automotive manufacturing and electrical installations, protecting critical wiring systems from heat, flame, and environmental hazards stands as a paramount concern for engineers and technicians worldwide. The YLW Black Flameproof Automotive Wiring Harness Protection Tape Heat-Resistant Wrapping Fabric Cloth Single Sided represents a breakthrough solution in industrial protection materials, engineered specifically to safeguard vital electrical connections against extreme operating conditions. This advanced protective wrapping combines exceptional flame resistance with superior heat management capabilities, making it an indispensable component for automotive manufacturers, electrical contractors, and maintenance professionals seeking reliable wire protection solutions.

As electrical systems become increasingly complex across automotive and industrial applications, the need for robust protection materials has never been more critical. Traditional wrapping solutions often fail under extreme temperatures or when exposed to flames, potentially leading to catastrophic system failures and safety hazards. This specialized fabric cloth addresses these challenges through innovative material engineering and rigorous testing protocols, delivering uncompromising protection for sensitive wiring harnesses in the most demanding environments.

Product Overview

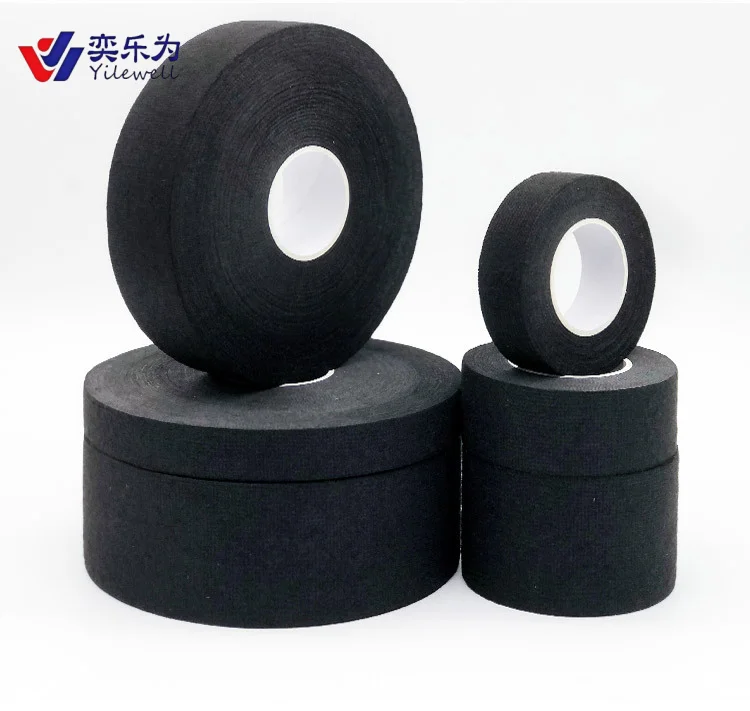

The YLW Black Flameproof Automotive Wiring Harness Protection Tape Heat-Resistant Wrapping Fabric Cloth Single Sided is manufactured using advanced textile technology that combines synthetic fibers with specialized flame-retardant treatments. This single-sided adhesive design allows for precise application while maintaining flexibility and conformability around complex wire bundles and irregular shapes commonly found in automotive and industrial electrical installations.

The distinctive black coloration serves both aesthetic and functional purposes, providing excellent UV resistance while maintaining a professional appearance that meets automotive industry standards. The fabric construction ensures optimal breathability, preventing moisture accumulation that could compromise electrical connections while delivering consistent protection against thermal stress and flame exposure. This wrapping material represents years of research and development in protective textile engineering, resulting in a product that exceeds industry expectations for reliability and performance.

Unlike conventional tape solutions that may become brittle or lose adhesion under extreme conditions, this heat-resistant fabric maintains its protective properties across a wide range of operating temperatures. The single-sided adhesive configuration simplifies installation while providing secure bonding that resists loosening during vehicle operation or machinery vibration, ensuring long-term protection integrity.

Features & Benefits

Advanced Flame Resistance Technology

The core strength of this protective wrapping lies in its exceptional flame resistance characteristics, achieved through proprietary chemical treatments and carefully selected base materials. When exposed to open flames or extreme heat sources, the fabric cloth exhibits self-extinguishing properties that prevent fire propagation along wiring harnesses, significantly reducing the risk of electrical fires in automotive and industrial applications.

This flame-retardant technology goes beyond simple fire resistance, incorporating thermal barriers that protect underlying wires from heat damage even during prolonged exposure to elevated temperatures. The material maintains structural integrity under extreme conditions, ensuring that protective coverage remains intact when it matters most, providing peace of mind for engineers and safety managers.

Superior Heat Management Properties

Heat resistance represents another critical advantage of the YLW Black Flameproof Automotive Wiring Harness Protection Tape Heat-Resistant Wrapping Fabric Cloth Single Sided, enabling reliable performance in high-temperature environments where conventional materials would fail. The specialized fiber composition dissipates heat effectively while maintaining flexibility, preventing the brittleness that often affects inferior protection materials under thermal stress.

The fabric construction allows for thermal expansion and contraction without compromising protective integrity, accommodating the natural movement of wiring systems during temperature cycling. This thermal stability ensures consistent protection throughout the operational life of electrical installations, reducing maintenance requirements and extending system reliability.

Flexible Installation and Conformability

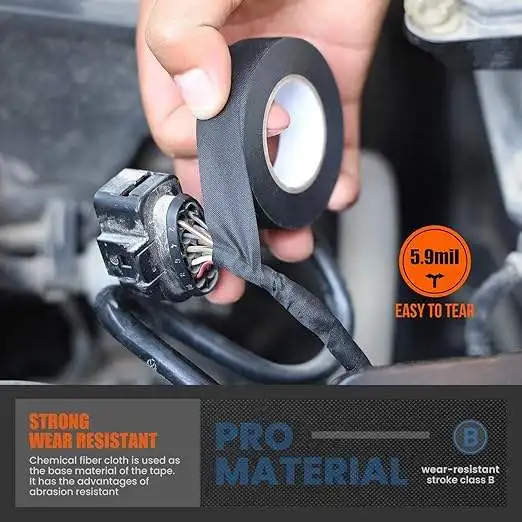

Installation versatility sets this wrapping fabric apart from rigid protection solutions, offering exceptional conformability that accommodates complex routing patterns and tight spaces common in modern automotive designs. The single-sided adhesive backing provides secure attachment while allowing for repositioning during installation, ensuring optimal coverage and professional appearance.

The fabric texture enhances grip and handling during application, reducing installation time and improving productivity for technicians working in challenging environments. This ease of use translates to reduced labor costs and improved installation quality, making it an attractive choice for both original equipment manufacturers and aftermarket applications.

Applications & Use Cases

Automotive manufacturing represents the primary application domain for this specialized protection tape, where it serves critical roles in safeguarding engine bay wiring, exhaust system harnesses, and high-temperature electrical connections. Modern vehicles generate significant heat in multiple zones, requiring protection materials that can withstand continuous exposure to elevated temperatures while maintaining electrical insulation properties.

Industrial machinery applications benefit significantly from the robust protection offered by this heat-resistant fabric, particularly in manufacturing environments where wiring systems operate near furnaces, welding equipment, or other high-temperature processes. The material's ability to maintain protective integrity under industrial conditions makes it invaluable for plant maintenance teams and equipment manufacturers.

Aerospace and marine applications present unique challenges where flame resistance and heat protection become critical safety requirements. The fabric cloth provides essential protection for aircraft wiring systems and marine electrical installations where fire safety regulations demand the highest levels of performance from protective materials.

Renewable energy systems, including solar installations and wind turbines, utilize this wrapping material to protect electrical connections exposed to environmental extremes and potential fire hazards. The long-term durability and weather resistance make it particularly suitable for outdoor installations requiring minimal maintenance over extended operational periods.

Quality Control & Compliance

Manufacturing excellence drives every aspect of production for the YLW Black Flameproof Automotive Wiring Harness Protection Tape Heat-Resistant Wrapping Fabric Cloth Single Sided, with comprehensive quality control protocols ensuring consistent performance across all production batches. Advanced testing procedures validate flame resistance, heat tolerance, and adhesive performance before materials reach end users, maintaining the highest standards of reliability and safety.

International compliance standards guide product development and manufacturing processes, ensuring compatibility with global automotive and industrial requirements. The material undergoes rigorous testing protocols that simulate real-world operating conditions, validating performance under extreme temperatures, flame exposure, and environmental stress factors commonly encountered in automotive and industrial applications.

Continuous quality monitoring throughout the manufacturing process employs advanced analytical techniques to verify material properties and adhesive performance characteristics. This commitment to quality excellence ensures that every roll of fabric cloth meets exacting specifications for flame resistance, heat tolerance, and long-term durability, providing consistent performance for critical protection applications.

Customization & Branding Options

Understanding the diverse requirements of global markets, comprehensive customization capabilities enable tailored solutions for specific application needs and branding requirements. The base material properties can be modified to optimize performance for particular operating environments, while maintaining the core flame resistance and heat protection characteristics that define product excellence.

Private labeling opportunities allow distributors and OEM manufacturers to offer this premium protection material under their own brands, supported by full technical documentation and application guidance. Custom packaging solutions accommodate various market preferences and distribution requirements, ensuring product presentation aligns with brand standards and customer expectations.

Technical consultation services support customization efforts, helping clients optimize material specifications for their specific applications while maintaining compliance with relevant industry standards. This collaborative approach ensures that customized solutions deliver optimal performance while meeting unique application requirements and market demands.

Packaging & Logistics Support

Efficient packaging systems protect product integrity during transportation while optimizing storage and handling efficiency for distributors and end users. The fabric cloth utilizes protective packaging materials that prevent contamination and physical damage while maintaining easy access for installation teams and technicians.

Global logistics capabilities ensure reliable delivery to international markets, with packaging designed to withstand the rigors of international shipping while maintaining product quality. Standardized packaging formats accommodate various order sizes and distribution requirements, from small-quantity specialty applications to large-volume industrial installations.

Inventory management support includes flexible packaging options that optimize storage efficiency while ensuring product freshness and adhesive performance. Clear product identification and handling instructions facilitate proper storage and application procedures, reducing waste and ensuring optimal performance in field installations.

Why Choose Us

Our commitment to excellence in protective material manufacturing spans decades of innovation and continuous improvement, establishing our position as a trusted metal packaging supplier and specialized protection material manufacturer serving global markets. This extensive experience enables deep understanding of customer requirements across automotive, industrial, and specialty applications, ensuring product solutions that exceed performance expectations.

International market presence reflects our dedication to serving diverse global customers with consistent quality and reliable supply capabilities. Our manufacturing expertise extends beyond traditional protection materials to include comprehensive OEM tin packaging solutions and custom metal packaging services, demonstrating versatility and technical capability across multiple industries and application domains.

Technical innovation drives product development initiatives that anticipate market needs and regulatory changes, ensuring that our protection materials remain at the forefront of industry standards. This forward-thinking approach, combined with rigorous quality control and customer-focused service, establishes long-term partnerships with distributors, manufacturers, and end users worldwide who depend on reliable protection solutions for their critical applications.

Conclusion

The YLW Black Flameproof Automotive Wiring Harness Protection Tape Heat-Resistant Wrapping Fabric Cloth Single Sided represents the pinnacle of protective material engineering, delivering uncompromising flame resistance and heat protection for critical electrical systems across automotive, industrial, and specialty applications. Its exceptional performance characteristics, combined with installation versatility and long-term durability, make it an essential component for maintaining electrical system integrity in demanding operating environments. The comprehensive quality control protocols and international compliance standards ensure consistent performance that meets the exacting requirements of global markets, while customization capabilities provide tailored solutions for specific application needs. For engineers, technicians, and manufacturers seeking reliable protection for critical wiring systems, this advanced fabric cloth delivers the performance, reliability, and peace of mind necessary for successful operations in the most challenging environments.

| item | value |

| Adhesive | Acrylic |

| Use | MASKING |

| Place of Origin | China |

| Adhesive Side | Single Sided |

| Material | Flannel |

| Type | Insulation Tape |

| Thickness | 0.3mm |

| Adhesive Type | Pressure Sensitive |

| Feature | Heat-resistant |

| Brand Name | YLW |

| Model Number | YLW-R001 |

| Design Printing | Offer Printing |

| cycle length | 10m |

| paper core | Customizable |

| Printing Handling | Offer printing |

| glue | Acrylic |

well

1. who are we?

We are based in Jiangsu, China, start from 2025,sell to Mid East(30.00%),Southeast Asia(20.00%),Central America(20.00%),North America(15.00%),South Asia(15.00%). There are total about - people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

automotive tape

4. why should you buy from us not from other suppliers?

-

5. what services can we provide?

Accepted Delivery Terms: -;

Accepted Payment Currency: -;

Accepted Payment Type: -;

Language Spoken: English