Introduction

Professional insulation solutions demand materials that combine exceptional thermal resistance with reliable adhesion properties. The YLW YLW-R001 Flannel Single-Sided Adhesive Pressure Sensitive Insulation Tape Heat-Resistant Flame Retardant 0.3mm Thickness 10m represents a breakthrough in advanced insulation technology, engineered specifically for demanding industrial applications. This premium flannel-based tape delivers superior heat resistance while maintaining excellent flame retardant characteristics, making it an essential component for electrical, automotive, and manufacturing professionals worldwide.

Modern industrial operations require insulation materials that can withstand extreme conditions while providing consistent performance over extended periods. This specialized pressure sensitive adhesive tape combines the natural insulating properties of flannel fabric with cutting-edge adhesive technology, creating a solution that addresses the complex challenges faced by engineers and technicians across multiple industries. The careful balance of flexibility, durability, and thermal protection makes this product an invaluable asset for critical applications where safety and reliability cannot be compromised.

Product Overview

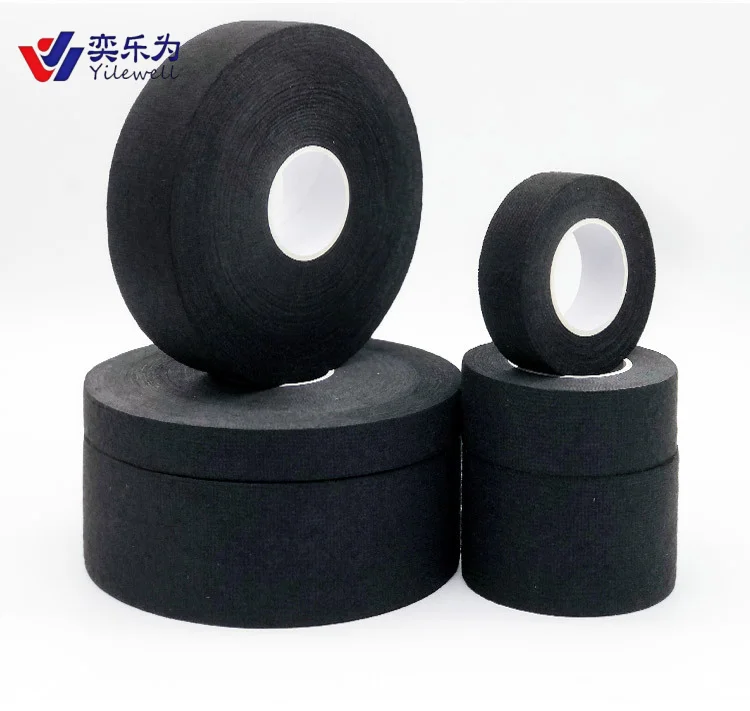

The YLW YLW-R001 Flannel Single-Sided Adhesive Pressure Sensitive Insulation Tape Heat-Resistant Flame Retardant 0.3mm Thickness 10m features a sophisticated construction that maximizes both insulation effectiveness and application versatility. The flannel substrate provides excellent thermal barrier properties while maintaining sufficient flexibility for complex installation requirements. This unique material composition ensures optimal performance in high-temperature environments where traditional insulation materials may fail or degrade over time.

The pressure sensitive adhesive system has been specifically formulated to maintain strong bonding characteristics across a wide temperature range, ensuring reliable attachment to various substrate materials commonly found in industrial applications. The single-sided configuration allows for precise application control while minimizing waste and reducing installation complexity. This design approach enables professionals to achieve consistent results regardless of environmental conditions or surface preparation constraints.

Advanced flame retardant properties are integrated throughout the material structure, providing essential safety protection in applications where fire resistance is critical. The comprehensive approach to flame retardation ensures that the tape maintains its protective characteristics even under prolonged exposure to elevated temperatures, making it suitable for use in sensitive electronic equipment, automotive systems, and industrial machinery where thermal management is paramount.

Features & Benefits

Superior Thermal Performance

The exceptional heat-resistant properties of this insulation tape stem from the carefully selected flannel substrate material, which naturally provides excellent thermal barrier characteristics. This thermal resistance capability enables the tape to maintain its structural integrity and adhesive performance even when exposed to elevated operating temperatures commonly encountered in industrial environments. The material's ability to resist thermal degradation ensures long-term reliability and consistent protection for critical components and systems.

Advanced Flame Retardant Technology

Safety considerations are paramount in industrial applications, and this tape incorporates sophisticated flame retardant chemistry that meets stringent safety requirements. The flame retardant properties are engineered to activate quickly when exposed to ignition sources, helping to prevent fire propagation and providing valuable time for safety systems to respond. This built-in safety feature makes the tape particularly valuable in applications where electrical components or high-temperature processes create potential fire hazards.

Optimized Adhesive Performance

The pressure sensitive adhesive system delivers reliable bonding performance across diverse substrate materials, including metals, plastics, and composite surfaces commonly found in industrial applications. The adhesive formulation maintains its tackiness and bonding strength over extended periods, ensuring that installations remain secure throughout the product's service life. This consistent adhesive performance reduces maintenance requirements and minimizes the risk of system failures due to insulation displacement or degradation.

Flexible Installation Characteristics

The flannel substrate provides excellent conformability, allowing the tape to adapt to irregular surfaces and complex geometries without compromising its insulation effectiveness. This flexibility is particularly valuable in applications involving curved surfaces, tight radius bends, or areas where traditional rigid insulation materials cannot be effectively applied. The material's ability to maintain intimate contact with substrate surfaces ensures optimal thermal transfer characteristics and prevents the formation of air gaps that could reduce insulation efficiency.

Applications & Use Cases

Electrical equipment manufacturers rely on the YLW YLW-R001 Flannel Single-Sided Adhesive Pressure Sensitive Insulation Tape Heat-Resistant Flame Retardant 0.3mm Thickness 10m for insulating sensitive components in transformers, motors, and control systems where thermal management is critical for safe operation. The tape's ability to provide both thermal barrier properties and flame retardancy makes it particularly valuable for protecting wire harnesses, terminal blocks, and junction boxes in high-temperature environments. The conformable nature of the flannel substrate allows for effective insulation of irregularly shaped components that would be difficult to protect using rigid insulation materials.

Automotive applications benefit significantly from the tape's combination of heat resistance and flame retardant properties, particularly in engine compartment installations where exposure to elevated temperatures and potential ignition sources requires robust protection. The material's ability to maintain adhesion under thermal cycling conditions makes it ideal for insulating fuel system components, exhaust heat shields, and electrical connections in vehicles where reliability and safety are paramount. The tape's resistance to automotive fluids and environmental contaminants ensures long-term performance in challenging operating conditions.

Industrial manufacturing processes often generate significant heat and require insulation solutions that can withstand continuous exposure to elevated temperatures while maintaining their protective characteristics. This specialized tape provides effective thermal barriers for process equipment, heating elements, and high-temperature piping systems where traditional insulation materials may degrade or lose effectiveness over time. The flame retardant properties add an essential safety margin in manufacturing environments where hot surfaces or electrical equipment create potential fire hazards.

HVAC systems and building applications utilize this insulation tape for protecting ductwork, pipe insulation, and equipment connections where thermal efficiency and fire safety are important considerations. The material's ability to conform to complex geometries makes it valuable for sealing gaps and joints in insulation systems, preventing thermal bridging that could reduce overall system efficiency. The pressure sensitive adhesive ensures secure attachment to various building materials without requiring additional mechanical fasteners or complicated installation procedures.

Quality Control & Compliance

Manufacturing excellence begins with rigorous material selection and quality control processes that ensure every roll of tape meets or exceeds performance specifications. The flannel substrate undergoes comprehensive testing to verify its thermal resistance characteristics, flame retardant properties, and dimensional stability under various environmental conditions. Advanced quality management systems monitor critical parameters throughout the production process, ensuring consistent material properties and adhesive performance across all manufactured batches.

International compliance standards play a crucial role in product development and manufacturing processes, with testing protocols designed to verify performance against recognized industry benchmarks for electrical insulation, flame resistance, and thermal stability. Independent testing laboratories conduct regular audits of material properties and manufacturing procedures, providing objective verification of product capabilities and ensuring ongoing compliance with evolving safety requirements. This commitment to regulatory compliance provides customers with confidence in product reliability and safety performance.

Environmental responsibility is integrated into manufacturing processes through careful selection of raw materials and adoption of sustainable production practices that minimize waste and environmental impact. The flame retardant chemistry is formulated to provide essential safety protection while meeting environmental regulations for chemical emissions and disposal requirements. Continuous improvement initiatives focus on enhancing product performance while reducing environmental footprint throughout the product lifecycle.

Customization & Branding Options

Understanding that different applications may require specific material characteristics or dimensions, comprehensive customization capabilities enable adaptation of the basic product design to meet unique customer requirements. Material thickness variations, adhesive formulations, and substrate treatments can be modified to optimize performance for specific operating conditions or installation requirements. These customization options ensure that customers receive insulation solutions perfectly matched to their application needs rather than compromising with standard products that may not provide optimal performance.

Private labeling and branding services support customers who require branded insulation products for their own distribution channels or internal specifications. Professional packaging design and printing capabilities enable the creation of custom product presentations that align with customer brand requirements while maintaining the high-quality standards expected in professional markets. This flexibility in branding and packaging supports both OEM applications and aftermarket distribution strategies.

Technical support services work closely with customers to develop application-specific solutions that maximize the effectiveness of the insulation tape in their particular use cases. Engineering consultation helps identify optimal installation techniques, surface preparation requirements, and system integration approaches that ensure reliable long-term performance. This collaborative approach to product development enables customers to achieve superior results while minimizing installation complexity and ongoing maintenance requirements.

Packaging & Logistics Support

Professional packaging systems protect the integrity of the pressure sensitive adhesive and flannel substrate during transportation and storage, ensuring that products arrive at their destination in optimal condition for immediate use. Moisture barrier packaging prevents environmental contamination that could affect adhesive performance, while protective cores prevent deformation that might compromise material properties or installation characteristics. These packaging innovations reflect understanding of the critical importance of material condition on application success.

Efficient logistics coordination enables reliable delivery schedules that support customer production planning and inventory management requirements. Flexible shipping options accommodate various order sizes and delivery timeframes, from emergency replacement needs to scheduled production runs. International shipping expertise ensures compliance with customs regulations and documentation requirements for global distribution, minimizing delays and complications in cross-border transactions.

Inventory management support helps customers optimize their material procurement strategies through demand forecasting assistance and flexible ordering arrangements. Technical storage recommendations ensure that customers maintain optimal material condition throughout their inventory cycles, preventing degradation that could affect product performance. These value-added services demonstrate commitment to customer success beyond simple product supply relationships.

Why Choose Us

With over two decades of experience in specialized adhesive and insulation material development, our company has established a reputation for engineering excellence and customer service that extends across multiple continents and industries. This extensive experience in international markets provides deep understanding of diverse application requirements and regulatory environments, enabling us to deliver solutions that meet the specific needs of customers in various geographic regions and industrial sectors.

As a recognized metal packaging manufacturer and custom tin box supplier with comprehensive capabilities in industrial materials, we understand the interconnected nature of modern manufacturing systems and the importance of reliable component suppliers. Our expertise extends beyond individual products to encompass system-level solutions that integrate seamlessly with existing processes and equipment. This broader perspective enables us to provide more effective support for complex applications where insulation performance is just one element of overall system success.

Advanced research and development capabilities drive continuous innovation in material science and manufacturing processes, ensuring that our products remain at the forefront of industry performance standards. Collaborative relationships with leading universities and research institutions provide access to emerging technologies and application methodologies that benefit our customers through improved product capabilities and enhanced application support. This commitment to innovation ensures that customers receive not just current solutions, but products positioned for future requirements and applications.

Conclusion

The YLW YLW-R001 Flannel Single-Sided Adhesive Pressure Sensitive Insulation Tape Heat-Resistant Flame Retardant 0.3mm Thickness 10m represents the convergence of advanced material science, manufacturing excellence, and practical application requirements in a single, highly effective insulation solution. Its unique combination of thermal resistance, flame retardant properties, and reliable adhesive performance makes it an essential component for professionals working in demanding industrial environments where safety and reliability cannot be compromised. The carefully engineered balance of flexibility, durability, and protective characteristics ensures optimal performance across a wide range of applications, from sensitive electronic equipment to high-temperature industrial processes. This comprehensive approach to insulation technology, combined with extensive customization capabilities and professional support services, establishes this product as a preferred choice for engineers and technicians who demand superior performance from their insulation materials.

| item | value |

| Adhesive | Acrylic |

| Use | MASKING |

| Place of Origin | China |

| Adhesive Side | Single Sided |

| Material | Flannel |

| Type | Insulation Tape |

| Thickness | 0.3mm |

| Adhesive Type | Pressure Sensitive |

| Feature | Heat-resistant |

| Brand Name | YLW |

| Model Number | YLW-R001 |

| Design Printing | Offer Printing |

| cycle length | 10m |

| paper core | Customizable |

| Printing Handling | Offer printing |

| glue | Acrylic |

well

1. who are we?

We are based in Jiangsu, China, start from 2025,sell to Mid East(30.00%),Southeast Asia(20.00%),Central America(20.00%),North America(15.00%),South Asia(15.00%). There are total about - people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

automotive tape

4. why should you buy from us not from other suppliers?

-

5. what services can we provide?

Accepted Delivery Terms: -;

Accepted Payment Currency: -;

Accepted Payment Type: -;

Language Spoken: English