Introduction

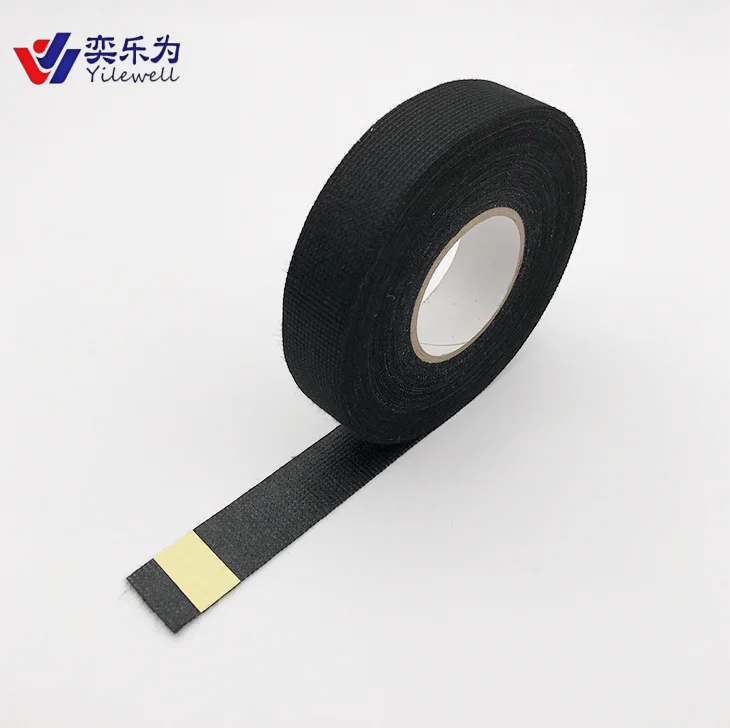

In today's demanding industrial landscape, professionals across various sectors require reliable adhesive solutions that can withstand challenging conditions while maintaining superior performance. The YLW YLW-R001 Single Sided Flannel Adhesive Pressure Sensitive Insulation Tape Heat-Resistant Masking Use represents a breakthrough in specialized tape technology, engineered to meet the most stringent requirements of modern manufacturing, automotive, and electronic applications. This innovative adhesive solution combines the softness and conformability of flannel backing with advanced pressure-sensitive adhesive properties, creating a versatile tool that excels in high-temperature environments where conventional tapes fail.

As industries continue to evolve toward more sophisticated processes and higher operating temperatures, the demand for specialized insulation and masking materials has grown exponentially. This premium flannel-backed tape addresses critical gaps in the market by offering exceptional thermal resistance while maintaining the flexibility and ease of application that professionals require for complex geometric surfaces and intricate masking operations.

Product Overview

The YLW YLW-R001 Single Sided Flannel Adhesive Pressure Sensitive Insulation Tape Heat-Resistant Masking Use features a unique construction that sets it apart from conventional masking and insulation tapes. The flannel backing material provides exceptional conformability, allowing the tape to follow complex contours and irregular surfaces while maintaining consistent adhesion throughout the application process. This characteristic makes it particularly valuable in applications where rigid tapes would create gaps or fail to provide adequate coverage.

The pressure-sensitive adhesive system has been specially formulated to deliver reliable performance across a wide temperature range, ensuring that the tape maintains its bonding strength even when exposed to elevated temperatures that would compromise standard adhesive products. The single-sided application design streamlines the installation process while providing the precise control that professionals require for accurate positioning and alignment in critical applications.

Beyond its primary function as a masking and insulation solution, this specialized tape serves as a versatile tool for protection, bundling, and temporary fixturing applications. The flannel backing material offers excellent tear resistance and dimensional stability, ensuring that the tape maintains its integrity throughout extended use periods and challenging environmental conditions.

Features & Benefits

Advanced Material Construction

The flannel backing material represents a significant advancement in tape substrate technology, offering a unique combination of properties that enhance both performance and usability. Unlike traditional paper or plastic-backed tapes, the flannel construction provides superior conformability, allowing the tape to adapt to irregular surfaces and complex geometries without creating stress points or adhesion failures. This flexibility proves invaluable in applications involving curved surfaces, textured materials, or intricate component configurations.

The material's inherent softness contributes to gentle application characteristics, reducing the risk of surface damage during installation and removal processes. This feature becomes particularly important when working with delicate finishes, precision-machined surfaces, or sensitive electronic components where conventional tapes might cause scratching or marking.

Thermal Performance Excellence

Heat resistance stands as one of the most critical performance attributes of the YLW YLW-R001 Single Sided Flannel Adhesive Pressure Sensitive Insulation Tape Heat-Resistant Masking Use, enabling its use in applications where temperature exposure would quickly degrade conventional adhesive products. The specialized adhesive formulation maintains its bonding properties and cohesive strength even when subjected to elevated temperatures, ensuring reliable performance throughout demanding thermal cycles.

This thermal stability extends beyond simple temperature resistance to include consistent performance during temperature fluctuations and thermal shock conditions. The tape's ability to maintain adhesion and physical properties during rapid temperature changes makes it ideal for applications involving heating and cooling cycles, such as automotive painting processes, electronic manufacturing, and industrial heat treatment operations.

Pressure-Sensitive Technology

The pressure-sensitive adhesive system provides immediate bonding upon application, eliminating the need for heat activation, solvent evaporation, or curing time that characterizes other adhesive technologies. This instant bonding capability streamlines production processes and reduces handling time, contributing to improved efficiency in high-volume manufacturing environments.

The adhesive's formulation balances strong initial tack with clean removability, ensuring that the tape provides secure attachment during use while allowing for residue-free removal when the application is complete. This characteristic proves essential in temporary masking applications where surface cleanliness must be maintained for subsequent processing steps.

Applications & Use Cases

The versatility of the YLW YLW-R001 Single Sided Flannel Adhesive Pressure Sensitive Insulation Tape Heat-Resistant Masking Use makes it suitable for an extensive range of industrial applications across multiple sectors. In automotive manufacturing and refinishing operations, the tape excels as a masking solution for paint booth applications, providing clean paint lines while withstanding the elevated temperatures associated with curing ovens and infrared heating systems.

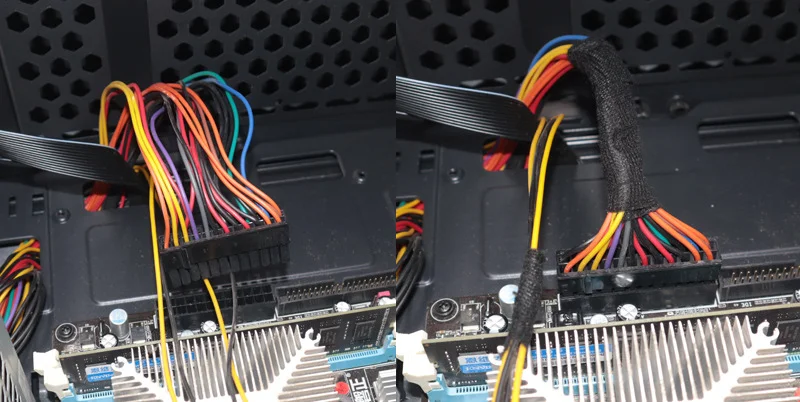

Electronics manufacturing represents another key application area where the tape's unique properties deliver significant value. The flannel backing's anti-static properties and gentle surface interaction make it ideal for protecting sensitive components during soldering, wave soldering, and reflow processes. The tape's ability to maintain adhesion at elevated temperatures ensures reliable masking during thermal processing while its clean removal characteristics prevent contamination of critical circuit board areas.

Industrial insulation applications benefit from the tape's thermal resistance and conformability, particularly in situations requiring temporary thermal barriers or insulation reinforcement. The flannel backing provides excellent thermal insulation properties while the pressure-sensitive adhesive ensures secure attachment to various substrate materials including metals, plastics, and composite materials.

Aerospace and defense applications leverage the tape's reliability and performance consistency in critical environments. The material's stability under temperature cycling and its resistance to environmental factors make it suitable for temporary protection during manufacturing processes, component assembly, and maintenance operations where precision and reliability are paramount.

In powder coating and industrial finishing operations, the tape serves as an essential masking tool, protecting areas that must remain coating-free while withstanding the high temperatures associated with curing ovens. The flannel backing's conformability ensures complete coverage of complex shapes and recessed areas, preventing coating penetration into masked regions.

Quality Control & Compliance

Manufacturing excellence drives every aspect of the YLW YLW-R001 Single Sided Flannel Adhesive Pressure Sensitive Insulation Tape Heat-Resistant Masking Use production process, ensuring consistent quality and performance across all product batches. Comprehensive quality control protocols monitor critical parameters including adhesive strength, thermal resistance, backing material properties, and dimensional accuracy throughout the manufacturing cycle.

Raw material sourcing follows stringent specifications to ensure that only premium-grade flannel materials and adhesive formulations enter the production process. Incoming inspection procedures verify material properties and consistency, while in-process monitoring systems track key performance indicators to maintain product uniformity and detect any deviations from established standards.

Environmental compliance represents a fundamental commitment in the product development and manufacturing process. The tape formulation adheres to relevant international standards regarding material safety and environmental impact, ensuring that users can confidently specify the product for applications requiring compliance with environmental regulations and workplace safety standards.

Batch tracking and documentation systems provide complete traceability from raw material receipt through final product shipment, enabling rapid response to any quality concerns and supporting customer quality assurance requirements. This comprehensive documentation approach ensures that users receive products that meet their specifications and performance expectations consistently.

Customization & Branding Options

Understanding that different applications require specific performance characteristics and dimensional requirements, comprehensive customization capabilities support the diverse needs of industrial users. Width variations accommodate everything from precision masking applications requiring narrow tape dimensions to large-area coverage applications where wider formats improve efficiency and coverage consistency.

Adhesive formulation modifications can address specific application requirements, such as enhanced temperature resistance for extreme-heat applications or modified tack levels for particular substrate compatibility. These customization options ensure optimal performance across the full spectrum of potential applications while maintaining the core benefits that define the product's value proposition.

As a trusted metal packaging manufacturer, our customization expertise extends beyond basic dimensional variations to include specialized packaging solutions that protect product integrity during storage and transportation. Custom tin box supplier capabilities ensure that large-volume users receive their tape products in packaging configurations that support their specific handling and dispensing requirements.

Private labeling options support distributors and resellers who require branded packaging for their market channels. These OEM tin packaging solutions maintain product protection while incorporating customer-specific graphics, part numbers, and identification systems that support their inventory management and customer service objectives.

Packaging & Logistics Support

Professional packaging systems protect the YLW YLW-R001 Single Sided Flannel Adhesive Pressure Sensitive Insulation Tape Heat-Resistant Masking Use during storage and transportation while facilitating efficient handling and dispensing in end-use applications. Individual roll packaging prevents contamination and maintains adhesive performance throughout the supply chain, while bulk packaging options support high-volume users with cost-effective logistics solutions.

Sustainable tin containers represent an innovative packaging approach that combines superior product protection with environmental responsibility. These metal packaging solutions provide excellent barrier properties against moisture, temperature fluctuations, and physical damage while supporting recycling initiatives that align with corporate sustainability objectives.

Logistics support systems accommodate diverse shipping requirements, from small sample quantities for evaluation purposes to full pallet loads for production applications. Flexible packaging configurations enable efficient transportation while minimizing packaging waste and shipping costs, contributing to overall supply chain efficiency for international customers.

Documentation support includes comprehensive product identification, handling instructions, and technical data sheets that ensure proper product use and storage. Multi-language labeling options support international distribution while maintaining compliance with local regulatory requirements and customer specifications.

Why Choose Us

With extensive experience serving international markets across diverse industrial sectors, our company has established a reputation for delivering innovative adhesive solutions that exceed customer expectations for quality and performance. This market presence reflects deep understanding of application requirements and the technical expertise necessary to develop products that address real-world challenges faced by industrial users worldwide.

As a premier metal packaging supplier, our comprehensive capabilities extend beyond product manufacturing to include complete supply chain support, technical consultation, and application engineering assistance. This integrated approach ensures that customers receive not just high-quality products, but complete solutions that optimize their operational efficiency and product performance.

Continuous investment in research and development maintains our position at the forefront of adhesive technology, enabling the introduction of innovative products like the YLW YLW-R001 Single Sided Flannel Adhesive Pressure Sensitive Insulation Tape Heat-Resistant Masking Use that address emerging market needs and evolving application requirements.

Global collaboration with leading manufacturers and distributors has established robust supply chain networks that ensure reliable product availability and consistent service levels regardless of customer location. This international presence supports customers' global operations while providing local service and technical support that enhances their competitive position in their respective markets.

Premium metal boxes and specialized packaging solutions demonstrate our commitment to product protection and customer satisfaction throughout the entire product lifecycle. These value-added services differentiate our offerings while supporting customers' quality objectives and operational requirements.

Conclusion

The YLW YLW-R001 Single Sided Flannel Adhesive Pressure Sensitive Insulation Tape Heat-Resistant Masking Use represents a significant advancement in specialized adhesive technology, combining innovative material construction with proven performance characteristics to address the demanding requirements of modern industrial applications. Its unique flannel backing, advanced pressure-sensitive adhesive system, and exceptional thermal resistance create a versatile solution that excels across multiple application areas while providing the reliability and consistency that professional users require. From automotive manufacturing and electronics production to aerospace applications and industrial finishing operations, this specialized tape delivers superior performance that enhances operational efficiency and product quality. The comprehensive customization options, professional packaging solutions, and extensive technical support ensure that customers receive complete solutions tailored to their specific requirements, backed by proven expertise and commitment to excellence that defines long-term partnership success in competitive global markets.

| item | value |

| Adhesive | Acrylic |

| Use | MASKING |

| Place of Origin | China |

| Adhesive Side | Single Sided |

| Material | Flannel |

| Type | Insulation Tape |

| Thickness | 0.3mm |

| Adhesive Type | Pressure Sensitive |

| Feature | Heat-resistant |

| Brand Name | YLW |

| Model Number | YLW-R001 |

| Design Printing | Offer Printing |

| cycle length | 10m |

| paper core | Customizable |

| Printing Handling | Offer printing |

| glue | Acrylic |

well

1. who are we?

We are based in Jiangsu, China, start from 2025,sell to Mid East(30.00%),Southeast Asia(20.00%),Central America(20.00%),North America(15.00%),South Asia(15.00%). There are total about - people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

automotive tape

4. why should you buy from us not from other suppliers?

-

5. what services can we provide?

Accepted Delivery Terms: -;

Accepted Payment Currency: -;

Accepted Payment Type: -;

Language Spoken: English