Introduction

Professional adhesive solutions demand exceptional reliability, thermal resistance, and residue-free performance across diverse industrial applications. The 0.26mm Black PET Cloth Non-Woven Adhesive Fabric Masking Tape 125 Degree Heat-Resistant Acrylic Sticker Harness Tape No Residue represents a breakthrough in specialized masking technology, engineered to meet the exacting requirements of automotive, electronics, and manufacturing industries worldwide. This advanced fabric-based adhesive tape combines superior heat resistance with clean removal properties, making it an indispensable tool for precision masking operations where conventional tapes fail to deliver consistent results.

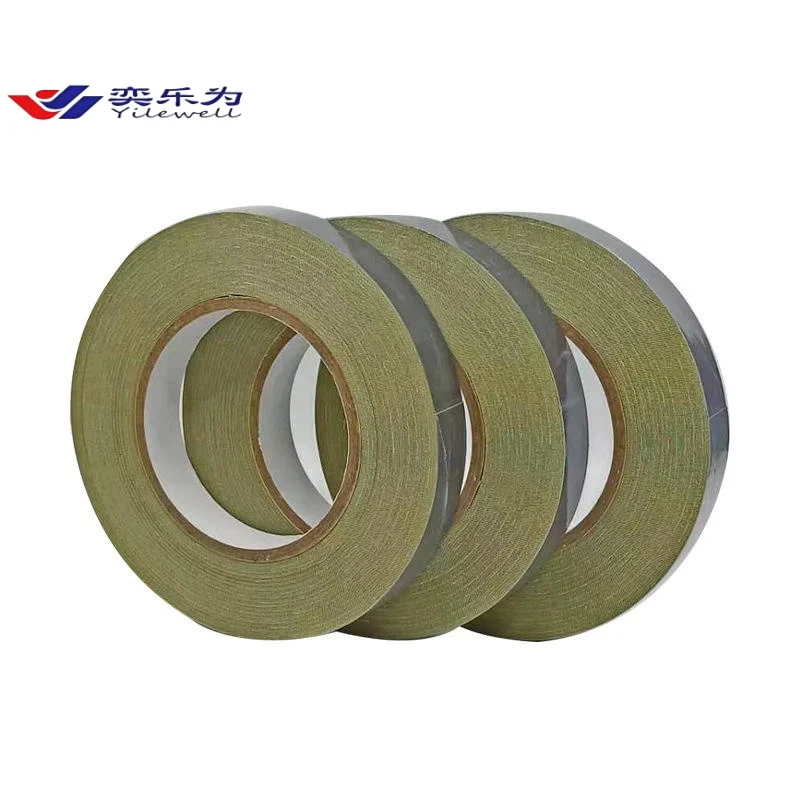

Manufactured using premium polyethylene terephthalate cloth substrate and advanced acrylic adhesive formulation, this professional-grade masking tape delivers outstanding performance under elevated temperatures while maintaining excellent conformability to complex surface geometries. The black coloration provides enhanced visibility during application and removal processes, ensuring precise placement and alignment in critical manufacturing environments where accuracy determines final product quality.

Product Overview

The 0.26mm Black PET Cloth Non-Woven Adhesive Fabric Masking Tape 125 Degree Heat-Resistant Acrylic Sticker Harness Tape No Residue features a sophisticated multi-layer construction designed to optimize performance across demanding industrial applications. The polyethylene terephthalate cloth backing provides exceptional tensile strength and dimensional stability, while the specialized non-woven structure ensures superior conformability around irregular surfaces and tight radii commonly encountered in wire harness assembly and component masking operations.

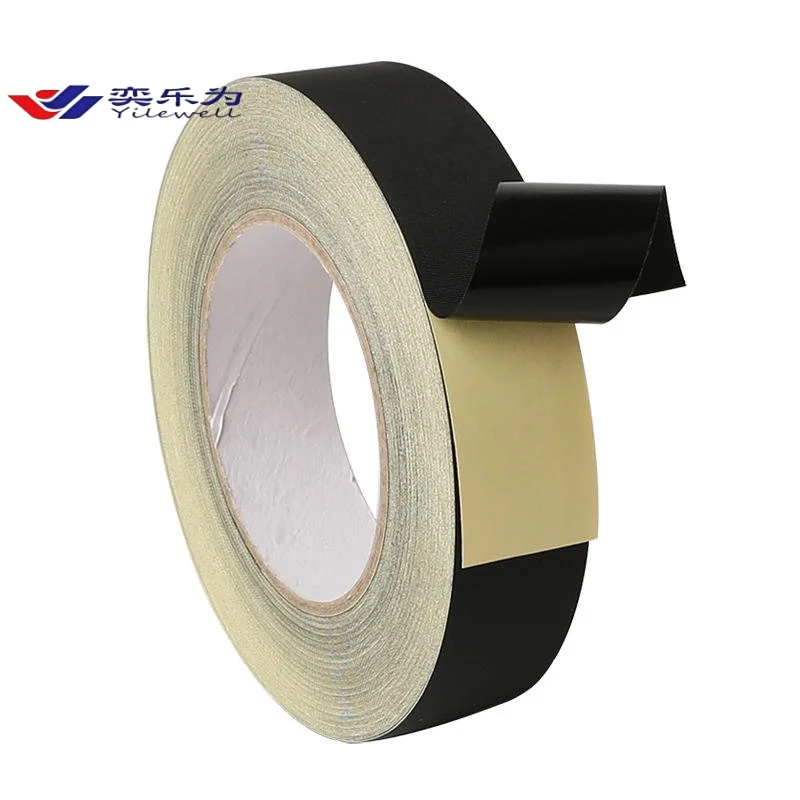

This premium fabric masking tape incorporates advanced acrylic adhesive technology specifically formulated to maintain secure bonding properties throughout extended exposure to elevated temperatures. The adhesive system exhibits controlled release characteristics, enabling clean removal without leaving residual traces on sensitive substrates including painted surfaces, plastics, and delicate electronic components. The black pigmentation offers enhanced contrast against light-colored surfaces, facilitating accurate placement and reducing application errors in high-volume production environments.

Features & Benefits

Superior Heat Resistance Performance

The thermal stability of this professional masking tape extends operational capability well beyond conventional paper or film-based alternatives, maintaining adhesive integrity and backing material properties under sustained elevated temperature exposure. This exceptional heat resistance makes it particularly valuable for powder coating operations, paint baking processes, and electronic assembly applications where thermal cycling occurs during manufacturing sequences.

Residue-Free Removal Technology

Advanced acrylic adhesive formulation ensures complete removal without adhesive transfer or surface contamination, protecting high-value substrates and eliminating costly post-processing cleanup operations. The controlled adhesion properties provide secure holding power during application while facilitating effortless removal even after extended dwell times, making this tape ideal for temporary protection and precision masking requirements.

Flexible Fabric Construction

The specialized cloth backing construction delivers exceptional conformability around complex geometries, tight bends, and irregular surface contours commonly encountered in harness taping and component protection applications. This flexibility enables single-piece coverage of challenging shapes while maintaining consistent adhesive contact and seal integrity throughout the protected area.

Applications & Use Cases

Wire harness assembly represents a primary application area for this 0.26mm Black PET Cloth Non-Woven Adhesive Fabric Masking Tape 125 Degree Heat-Resistant Acrylic Sticker Harness Tape No Residue, where its combination of heat resistance, flexibility, and clean removal properties proves invaluable for bundling and protecting electrical connections in automotive and aerospace applications. The fabric backing provides abrasion resistance while accommodating the natural movement and flexing of wire bundles during installation and service life.

Electronic component masking during soldering and assembly processes benefits significantly from the thermal stability and residue-free characteristics of this specialized tape. Surface mount technology applications, where precise temperature profiles must be maintained without compromising adjacent components, rely on the consistent performance and clean removal properties that this advanced masking solution delivers across multiple thermal cycles.

Powder coating and liquid painting operations utilize this heat-resistant fabric tape for protecting threaded holes, electrical connections, and precision surfaces that must remain coating-free. The elevated temperature capability ensures adhesive integrity throughout the curing process, while the residue-free removal eliminates the risk of contaminating finished surfaces or compromising subsequent assembly operations.

General manufacturing applications including temporary component protection, surface preparation masking, and quality control identification benefit from the versatility and reliability of this professional-grade adhesive tape. The black coloration provides excellent visibility for inspection and removal processes, while the fabric construction offers superior tear resistance compared to conventional film-based alternatives.

Quality Control & Compliance

Rigorous quality assurance protocols govern every aspect of production for this 0.26mm Black PET Cloth Non-Woven Adhesive Fabric Masking Tape 125 Degree Heat-Resistant Acrylic Sticker Harness Tape No Residue, ensuring consistent performance characteristics and reliability across all production batches. Advanced testing procedures validate adhesive strength, temperature resistance, and removal characteristics under controlled laboratory conditions that simulate real-world application environments.

Material composition verification ensures compliance with international standards for industrial adhesive products, while environmental testing confirms performance stability across varying humidity, temperature, and atmospheric pressure conditions commonly encountered in global manufacturing facilities. Batch tracking and documentation systems provide complete traceability for quality assurance and regulatory compliance requirements.

Packaging integrity controls protect product quality from manufacturing through distribution, utilizing moisture-resistant materials and proper environmental controls to preserve adhesive properties and backing material characteristics. Regular audits of storage and handling procedures ensure optimal product condition upon delivery to end-users worldwide.

Customization & Branding Options

Flexible customization capabilities accommodate diverse customer requirements for specialized widths, lengths, and packaging configurations tailored to specific application needs and operational preferences. Custom slitting services enable precision width specifications that optimize material utilization and application efficiency in automated dispensing systems and high-volume production environments.

Private labeling options allow distributors and OEM customers to incorporate their branding elements while maintaining the superior performance characteristics of this premium fabric masking tape. Custom packaging solutions include specialized core sizes, roll configurations, and protective packaging that align with existing inventory management systems and storage requirements.

Technical consultation services support customers in optimizing tape selection and application parameters for specific use cases, ensuring maximum performance and cost-effectiveness. Application engineering expertise helps identify the most suitable configuration and installation procedures for challenging or unique masking requirements.

Packaging & Logistics Support

Professional packaging solutions protect product integrity throughout the supply chain while optimizing storage efficiency and handling convenience for distributors and end-users. Moisture-resistant outer packaging prevents environmental contamination that could compromise adhesive performance, while clear product identification facilitates accurate inventory management and order fulfillment.

Standardized packaging configurations enable efficient palletization and container loading for international shipments, while accommodating diverse regional preferences for case quantities and roll sizes. Protective inner packaging shields individual rolls from mechanical damage during transportation and storage, ensuring consistent product quality upon receipt.

Comprehensive documentation accompanies each shipment, including material safety data sheets, application guidelines, and technical specifications that support safe handling and optimal performance in customer facilities. Lot identification and traceability information enables effective inventory rotation and quality assurance tracking throughout the distribution network.

Why Choose Us

With over two decades of experience serving international markets, our company has established a reputation for delivering innovative adhesive solutions that exceed customer expectations across diverse industrial sectors. Our extensive collaboration with leading manufacturers worldwide has refined our understanding of application-specific requirements and enabled continuous improvement in product performance and reliability.

As a recognized metal packaging manufacturer and custom tin box supplier, we understand the precision and quality standards that define successful industrial operations. Our expertise extends beyond traditional packaging to encompass specialized adhesive solutions like this 0.26mm Black PET Cloth Non-Woven Adhesive Fabric Masking Tape 125 Degree Heat-Resistant Acrylic Sticker Harness Tape No Residue, leveraging advanced materials science and manufacturing capabilities to deliver superior performance solutions.

Comprehensive technical support and application engineering services distinguish our customer relationships, providing ongoing consultation and problem-solving expertise that helps optimize performance and cost-effectiveness. Our global distribution network ensures reliable supply chain support with local technical assistance available in major markets worldwide, facilitating seamless integration into existing procurement and operations frameworks.

Conclusion

The 0.26mm Black PET Cloth Non-Woven Adhesive Fabric Masking Tape 125 Degree Heat-Resistant Acrylic Sticker Harness Tape No Residue represents the convergence of advanced materials technology and application-specific engineering, delivering exceptional performance for demanding industrial masking requirements. Its unique combination of heat resistance, fabric flexibility, and residue-free removal properties addresses critical challenges across automotive, electronics, and general manufacturing applications where conventional masking solutions prove inadequate. The sophisticated construction and reliable performance characteristics make this professional-grade tape an essential component for manufacturers seeking to optimize production efficiency while maintaining the highest quality standards in their finished products.

| item | value |

| Adhesive | Acrylic |

| Use | MASKING |

| Place of Origin | China |

| Adhesive Side | Single Sided |

| Material | Cloth |

| Type | Adhesive Sticker |

| Thickness | 0.26mm |

| Adhesive Type | Pressure Sensitive |

| Feature | Heat-resistant |

| Brand Name | YLW |

| Model Number | YLW-- B005 |

| Design Printing | No printing |

| cycle length | 25m |

| paper core | No paper core. |

| Printing Handling | No printing |

| glue | Acrylic |

well

1. who are we?

We are based in Jiangsu, China, start from 2025,sell to Mid East(30.00%),Southeast Asia(20.00%),Central America(20.00%),North America(15.00%),South Asia(15.00%). There are total about - people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

automotive tape

4. why should you buy from us not from other suppliers?

-

5. what services can we provide?

Accepted Delivery Terms: -;

Accepted Payment Currency: -;

Accepted Payment Type: -;

Language Spoken: English