Introduction

In today's demanding automotive and industrial environments, electrical systems require robust protection that can withstand extreme temperatures while maintaining optimal performance. The 125 Degree Heat-Resistant Black PET Cloth Fabric Automotive Wire Harness Tape Acrylic Pressure Sensitive Adhesive Non-Woven represents a breakthrough in protective tape technology, engineered specifically for high-temperature applications where conventional adhesive solutions fail. This advanced tape solution combines the durability of PET cloth fabric with the reliability of acrylic pressure sensitive adhesive, creating an ideal protective barrier for wire harnesses, cable assemblies, and electrical components in automotive, aerospace, and heavy machinery applications.

As industries continue to push the boundaries of performance and efficiency, the need for specialized protective materials has never been greater. This innovative tape addresses the critical challenges faced by manufacturers and engineers who require dependable insulation and bundling solutions that can maintain their integrity under sustained heat exposure while providing excellent adhesion properties and mechanical strength.

Product Overview

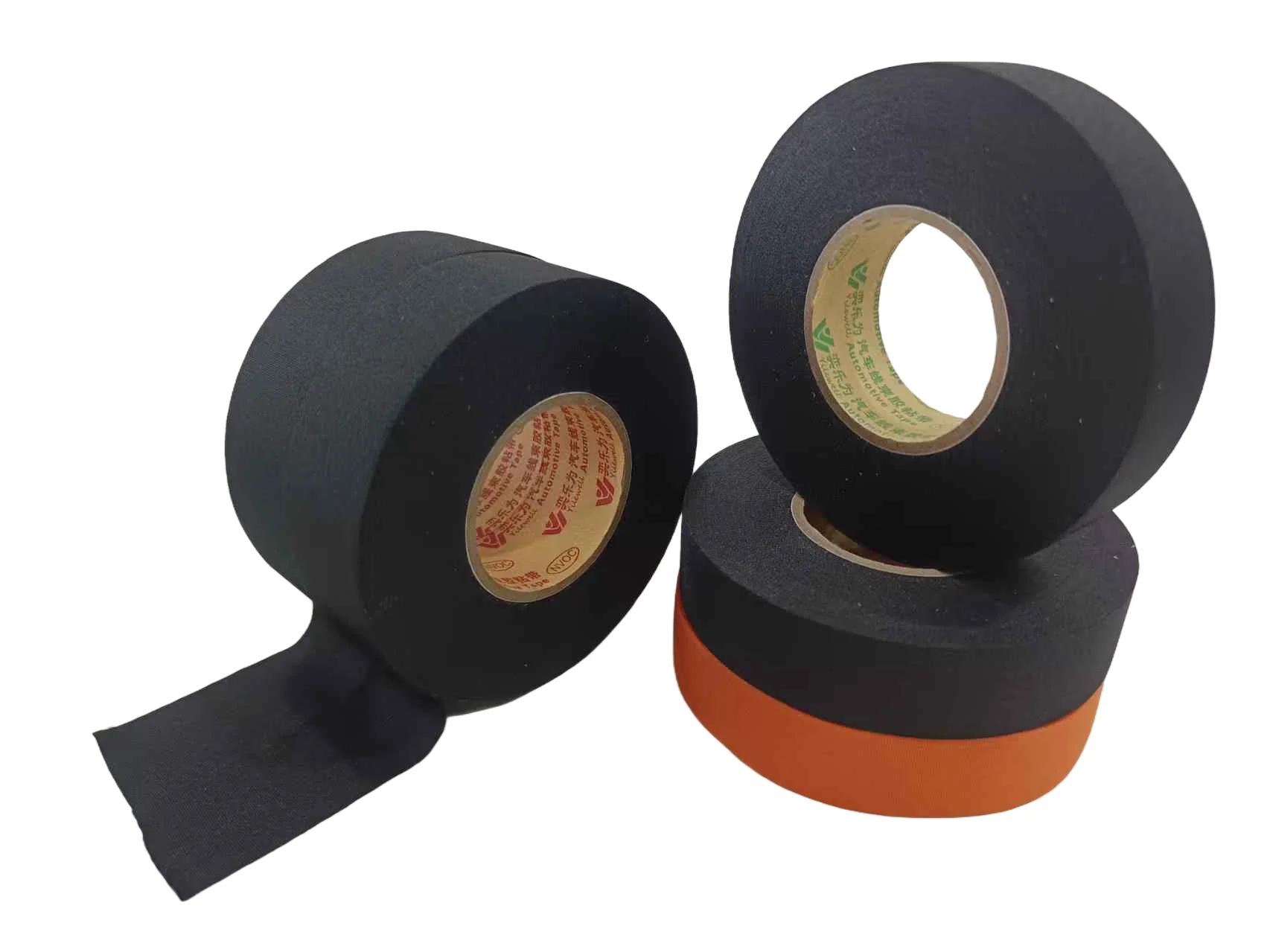

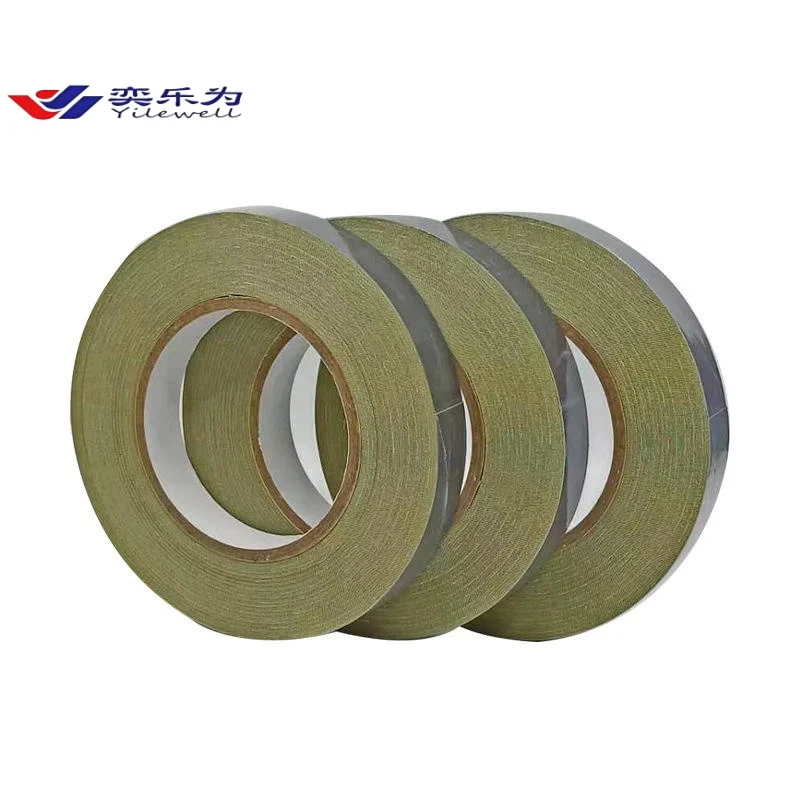

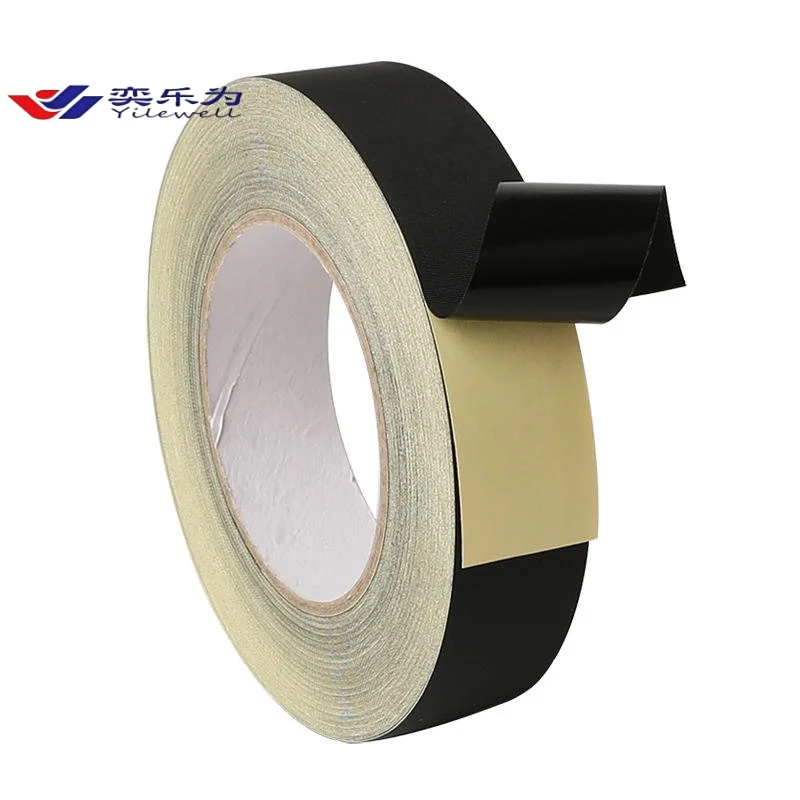

The 125 Degree Heat-Resistant Black PET Cloth Fabric Automotive Wire Harness Tape Acrylic Pressure Sensitive Adhesive Non-Woven is a premium-grade protective tape specifically designed for demanding electrical applications. Built on a foundation of polyethylene terephthalate cloth fabric, this tape delivers exceptional dimensional stability and mechanical strength while maintaining flexibility for easy application around complex wire harness configurations.

The black coloration not only provides a professional aesthetic finish but also offers enhanced UV resistance and thermal management properties. The non-woven construction ensures consistent thickness and uniform adhesive distribution, while the acrylic pressure sensitive adhesive system provides reliable bonding performance across a wide range of substrates and environmental conditions. This combination creates a versatile solution that meets the stringent requirements of modern automotive electrical systems and industrial wire management applications.

Manufactured using advanced coating technologies and precision manufacturing processes, this tape represents the culmination of extensive research and development in adhesive science and textile engineering. The result is a product that consistently delivers superior performance in high-temperature environments where traditional tape solutions would deteriorate or fail completely.

Features & Benefits

Advanced Heat Resistance Technology

The exceptional thermal performance of this 125 Degree Heat-Resistant Black PET Cloth Fabric Automotive Wire Harness Tape Acrylic Pressure Sensitive Adhesive Non-Woven stems from its carefully engineered material composition. The PET cloth fabric backing provides inherent thermal stability, maintaining its structural integrity and protective properties even under sustained exposure to elevated temperatures. This thermal resistance ensures that wire harnesses remain properly protected and organized throughout their operational lifespan, even in engine compartments, industrial ovens, and other high-heat environments.

Superior Adhesive Performance

The acrylic pressure sensitive adhesive system represents a significant advancement in tape technology, offering excellent initial tack combined with long-term holding power. Unlike rubber-based adhesives that can soften and migrate under heat exposure, the acrylic formulation maintains its adhesive properties and dimensional stability across the entire temperature range. This ensures reliable performance without adhesive transfer, residue buildup, or bond failure that could compromise system integrity.

Mechanical Durability and Flexibility

The non-woven PET cloth construction provides exceptional tear resistance and conformability, allowing the tape to adapt to irregular surfaces and complex geometries without compromising its protective capabilities. This flexibility is crucial for automotive wire harness applications where vibration, thermal cycling, and mechanical stress are constant factors. The tape maintains its protective seal and adhesive bond even under dynamic loading conditions.

Chemical and Environmental Resistance

Beyond thermal performance, this specialized tape offers excellent resistance to automotive fluids, industrial chemicals, and environmental contaminants. The black PET fabric provides UV protection while the acrylic adhesive resists degradation from exposure to oils, fuels, and cleaning solvents commonly encountered in automotive and industrial environments.

Applications & Use Cases

The versatility of the 125 Degree Heat-Resistant Black PET Cloth Fabric Automotive Wire Harness Tape Acrylic Pressure Sensitive Adhesive Non-Woven makes it an essential component across multiple industries and applications. In automotive manufacturing, this tape serves as the primary protection and organization solution for engine compartment wiring, exhaust system harnesses, and under-hood electrical components where extreme temperatures and harsh environmental conditions are standard operating parameters.

Industrial machinery and equipment manufacturers rely on this advanced tape for protecting control cables, sensor wiring, and power distribution systems in high-temperature processing environments. Manufacturing facilities utilizing ovens, furnaces, and heat treatment equipment benefit from the tape's ability to maintain protective integrity without degradation or failure that could lead to costly downtime or safety hazards.

Aerospace and defense applications represent another critical market where this tape's exceptional performance characteristics prove invaluable. Aircraft engine compartments, spacecraft thermal protection systems, and military vehicle electrical installations all require the level of thermal resistance and reliability that this specialized tape provides. The consistent performance under extreme conditions makes it an ideal choice for mission-critical applications where failure is not an option.

Marine and offshore applications also benefit significantly from this tape's environmental resistance properties. Engine rooms, processing equipment, and electrical installations on ships and offshore platforms are subject to temperature extremes, chemical exposure, and mechanical stress that demand the superior protection offered by this advanced tape solution.

Quality Control & Compliance

Manufacturing excellence is maintained through comprehensive quality control systems that ensure every roll of 125 Degree Heat-Resistant Black PET Cloth Fabric Automotive Wire Harness Tape Acrylic Pressure Sensitive Adhesive Non-Woven meets or exceeds the stringent performance requirements of modern industrial applications. Advanced testing protocols verify thermal performance, adhesive strength, and environmental resistance properties throughout the production process.

Raw material qualification programs ensure that only premium-grade PET fabrics and acrylic adhesive formulations are utilized in production. Incoming inspection procedures verify that all materials meet established specifications for thermal stability, mechanical properties, and chemical resistance before entering the manufacturing process. This upstream quality control approach prevents defective materials from affecting final product performance.

Environmental and safety compliance represents a fundamental aspect of the manufacturing philosophy, with production processes designed to minimize environmental impact while ensuring worker safety. The tape formulation excludes hazardous substances commonly found in competitive products, making it suitable for use in environmentally sensitive applications and facilitating end-of-life disposal or recycling.

International quality standards compliance ensures that this specialized tape meets the requirements of global automotive, aerospace, and industrial equipment manufacturers. Regular third-party testing and certification maintain compliance with evolving industry standards and regulatory requirements across multiple international markets.

Customization & Branding Options

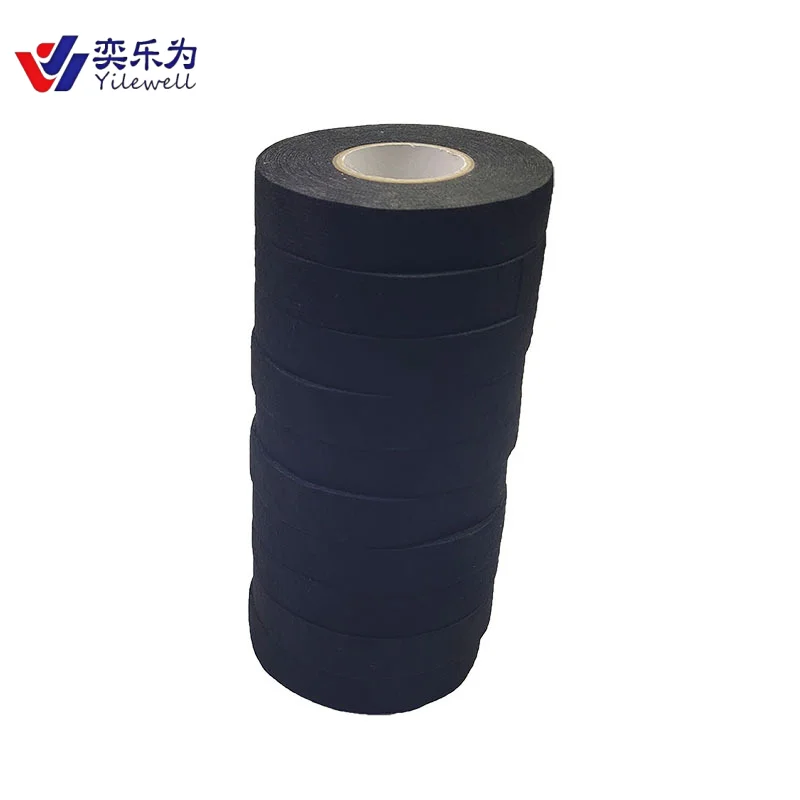

Understanding that different applications require specific performance characteristics and aesthetic requirements, comprehensive customization capabilities are available for the 125 Degree Heat-Resistant Black PET Cloth Fabric Automotive Wire Harness Tape Acrylic Pressure Sensitive Adhesive Non-Woven. Width variations can be tailored to specific application requirements, from narrow precision applications to wide-format coverage needs.

Adhesive formulation modifications allow for optimization of bonding characteristics for specific substrate materials or environmental conditions. Whether enhanced initial tack is required for difficult-to-bond surfaces or modified cure characteristics are needed for specialized applications, custom adhesive solutions can be developed to meet unique performance requirements.

Private labeling and branding services enable distributors and equipment manufacturers to incorporate this advanced tape technology into their product lines under their own brand identity. Custom packaging solutions, including specialized core sizes, roll lengths, and packaging formats, can be configured to match specific distribution or end-user requirements.

Color customization options extend beyond the standard black configuration to include other colors for coding, identification, or aesthetic purposes while maintaining the same exceptional thermal and adhesive performance characteristics. Custom printing capabilities allow for product identification, specification marking, or branding elements to be incorporated directly onto the tape surface.

Packaging & Logistics Support

Efficient distribution and handling are facilitated through sophisticated packaging systems designed to protect product integrity while optimizing logistics efficiency. Individual rolls are carefully wound and packaged to prevent edge damage, contamination, or adhesive transfer during storage and transportation. Protective packaging materials are selected to provide moisture barrier properties while allowing for easy identification and handling.

Bulk packaging configurations are available for high-volume users, incorporating space-efficient designs that reduce shipping costs while maintaining product protection. Palletization systems are optimized for standard shipping containers and warehouse handling equipment, facilitating efficient distribution through global supply chains.

Storage condition requirements are clearly specified to ensure optimal product performance throughout the distribution cycle. Temperature and humidity guidelines help distributors and end users maintain product quality from manufacturer to final application. Shelf life information and storage recommendations ensure that performance characteristics remain consistent over extended storage periods.

Documentation and traceability systems provide complete product history and specification verification, supporting quality assurance requirements in regulated industries. Batch tracking capabilities enable rapid identification and resolution of any quality issues while facilitating compliance with automotive and aerospace traceability requirements.

Why Choose Us

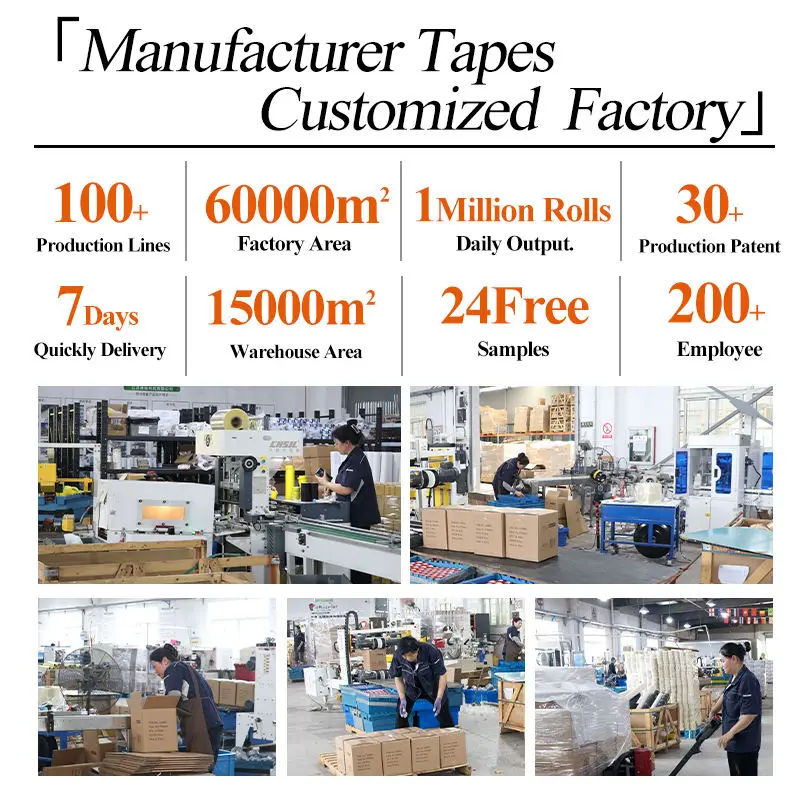

With over two decades of experience in advanced adhesive technologies and specialty tape manufacturing, our company has established itself as a trusted metal packaging supplier and innovator in protective material solutions for demanding industrial applications. Our global presence spans multiple continents, serving automotive manufacturers, aerospace companies, and industrial equipment producers with consistently reliable products that meet the highest performance standards.

Our commitment to research and development has resulted in numerous breakthrough products, including this revolutionary 125 Degree Heat-Resistant Black PET Cloth Fabric Automotive Wire Harness Tape Acrylic Pressure Sensitive Adhesive Non-Woven. Continuous investment in manufacturing technology and quality systems ensures that we remain at the forefront of adhesive tape innovation while maintaining the production capacity to serve global markets reliably.

Technical support capabilities extend far beyond product supply, with experienced application engineers available to assist with product selection, application optimization, and custom solution development. This collaborative approach has enabled successful partnerships with leading manufacturers across multiple industries, resulting in improved product performance and reduced total cost of ownership.

Sustainability initiatives and environmental responsibility guide our manufacturing processes and product development efforts. Advanced production technologies minimize waste generation while maximizing resource efficiency, supporting our customers' environmental objectives while delivering superior product performance. Our commitment to sustainable manufacturing practices positions us as a responsible custom tin box supplier for environmentally conscious organizations.

Conclusion

The 125 Degree Heat-Resistant Black PET Cloth Fabric Automotive Wire Harness Tape Acrylic Pressure Sensitive Adhesive Non-Woven represents the pinnacle of protective tape technology, combining advanced materials science with precision manufacturing to deliver unmatched performance in high-temperature applications. Its exceptional thermal resistance, superior adhesive properties, and mechanical durability make it the ideal solution for protecting critical electrical systems in automotive, aerospace, and industrial environments where conventional tape solutions cannot provide adequate protection.

Through comprehensive quality control, extensive customization capabilities, and reliable global distribution, this innovative tape solution provides manufacturers and engineers with the confidence that their electrical systems will remain protected and operational under the most demanding conditions. The combination of proven performance, technical support, and manufacturing excellence establishes this product as the preferred choice for professionals who demand the highest levels of reliability and performance from their protective material solutions.

| item | value |

| Adhesive | Acrylic |

| Use | MASKING |

| Place of Origin | China |

| Adhesive Side | Single Sided |

| Material | Cloth |

| Type | Adhesive Sticker |

| Thickness | 0.26mm |

| Adhesive Type | Pressure Sensitive |

| Feature | Heat-resistant |

| Brand Name | YLW |

| Model Number | YLW-- B005 |

| Design Printing | No printing |

| cycle length | 25m |

| paper core | No paper core. |

| Printing Handling | No printing |

| glue | Acrylic |

well

1. who are we?

We are based in Jiangsu, China, start from 2025,sell to Mid East(30.00%),Southeast Asia(20.00%),Central America(20.00%),North America(15.00%),South Asia(15.00%). There are total about - people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

automotive tape

4. why should you buy from us not from other suppliers?

-

5. what services can we provide?

Accepted Delivery Terms: -;

Accepted Payment Currency: -;

Accepted Payment Type: -;

Language Spoken: English