Introduction

Professional automotive wiring protection demands solutions that combine durability, flexibility, and reliable performance across diverse operating environments. The 25M Single-Sided Auto Wiring Fabric Wrap Harness Bundle Insulation Heat-Resistant Waterproof Acrylic Adhesive Sticker Cloth harness tape represents a comprehensive approach to wire management and protection in modern vehicle systems. This specialized fabric wrap delivers exceptional protection against environmental hazards while maintaining the flexibility required for complex automotive installations.

Engineered specifically for automotive applications, this fabric harness tape addresses the critical need for reliable wire bundle protection in vehicles ranging from passenger cars to commercial trucks. The advanced fabric construction provides superior conformability around wire bundles while the waterproof acrylic adhesive ensures secure attachment even in challenging conditions. This combination of materials and design makes it an essential component for automotive manufacturers, repair facilities, and aftermarket installers seeking professional-grade wire protection solutions.

Product Overview

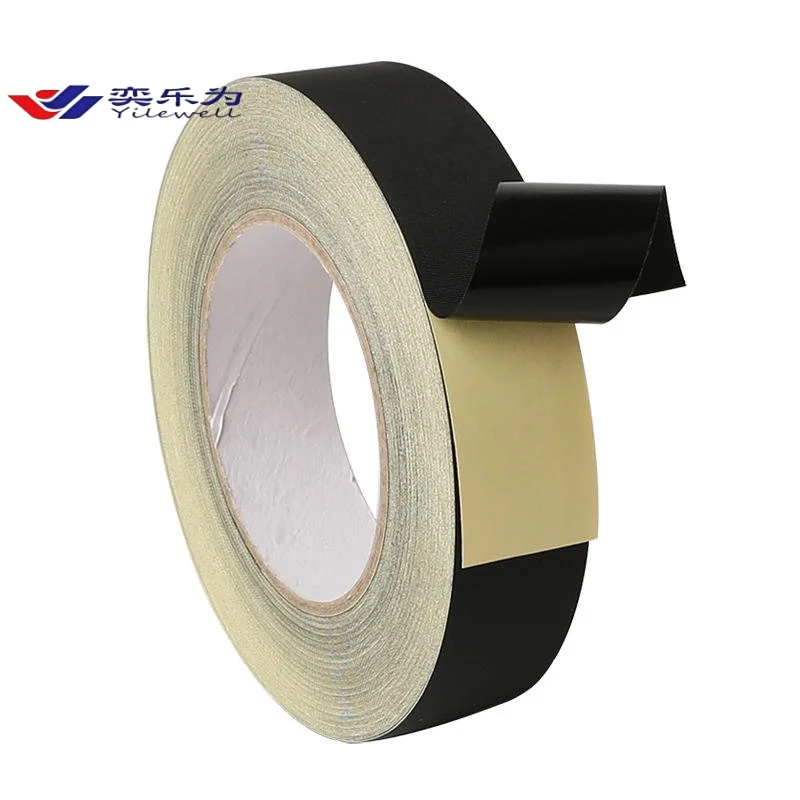

The fabric wrap harness tape features a single-sided adhesive configuration optimized for automotive wire bundle applications. The base material combines high-quality cloth fibers with specialized treatments that enhance heat resistance and waterproof performance. This construction methodology ensures the tape maintains its protective properties across temperature extremes commonly encountered in automotive environments, from engine compartments to exterior chassis applications.

The acrylic adhesive system provides immediate tack with excellent long-term bonding strength, eliminating the need for additional securing methods in most applications. The fabric substrate offers superior abrasion resistance compared to traditional vinyl tapes, making it ideal for areas where wire bundles may experience mechanical stress or contact with vehicle components. The waterproof characteristics protect against moisture intrusion, preventing corrosion and electrical faults that can compromise vehicle reliability.

This automotive wiring solution incorporates advanced manufacturing processes that ensure consistent quality and performance across the entire roll length. The precision coating of the acrylic adhesive creates uniform bonding characteristics while the fabric base maintains dimensional stability under varying temperature and humidity conditions. These engineering considerations make the 25M Single-Sided Auto Wiring Fabric Wrap Harness Bundle Insulation Heat-Resistant Waterproof Acrylic Adhesive Sticker Cloth harness tape suitable for both original equipment manufacturer applications and aftermarket installations.

Features & Benefits

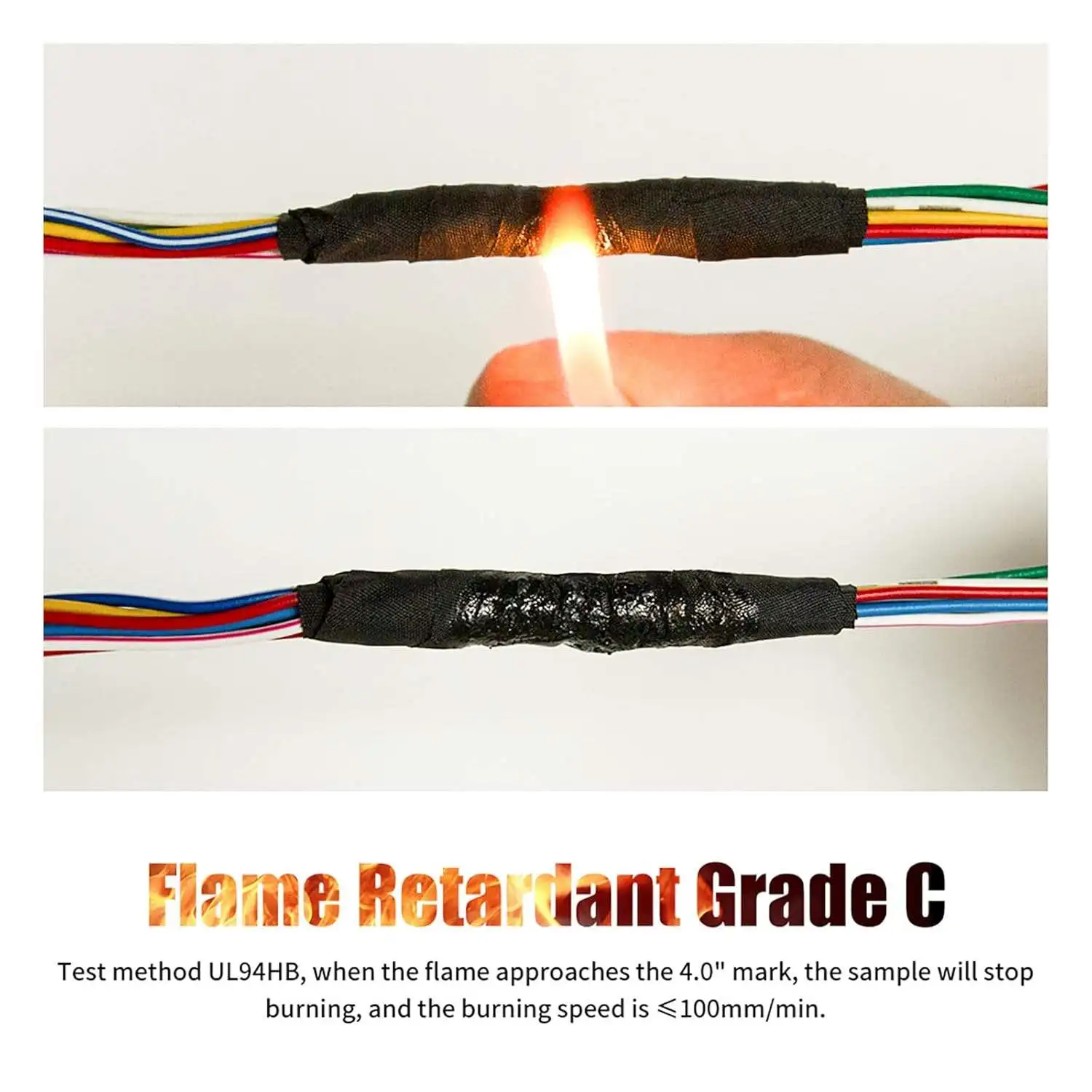

Advanced Heat Resistance Technology

The heat-resistant properties of this fabric harness tape enable reliable performance in high-temperature automotive environments. Engine compartment applications, exhaust system proximity, and transmission housing installations all benefit from the thermal stability engineered into the fabric construction. The specialized fiber composition maintains structural integrity and adhesive performance even when exposed to sustained elevated temperatures, preventing tape failure that could compromise wire protection.

Superior Waterproof Protection

Moisture protection represents a critical aspect of automotive wire management, and this fabric wrap delivers comprehensive waterproof performance. The combination of treated fabric fibers and waterproof acrylic adhesive creates a barrier system that prevents water intrusion while allowing the tape to conform closely to irregular wire bundle configurations. This waterproof capability extends beyond simple water resistance to include protection against automotive fluids, road salt, and other corrosive substances encountered in vehicle operation.

Flexible Fabric Construction

The cloth-based substrate provides exceptional flexibility and conformability, enabling the tape to wrap tightly around complex wire bundle configurations without creating stress points or gaps in coverage. This flexibility proves particularly valuable in automotive applications where wire bundles must navigate around components, through grommets, and along curved pathways. The fabric construction also offers superior tear resistance compared to film-based alternatives, reducing the likelihood of accidental damage during installation.

Professional-Grade Adhesive System

The acrylic adhesive formulation delivers reliable bonding performance across diverse automotive substrates while maintaining removability when service access is required. The single-sided application allows for overlapping installation techniques that create seamless protection along extended wire runs. The adhesive system resists degradation from temperature cycling, vibration, and exposure to automotive chemicals, ensuring long-term installation integrity.

Applications & Use Cases

Automotive manufacturing facilities utilize this fabric harness tape extensively throughout vehicle assembly processes. Engine compartment wiring requires protection from heat, vibration, and fluid exposure, making the heat-resistant and waterproof characteristics essential for reliable operation. Transmission and drivetrain applications benefit from the tape's ability to maintain adhesion and protection in environments subject to temperature extremes and mechanical stress.

Aftermarket automotive installations represent another significant application area for this specialized tape. Custom audio system installations, auxiliary lighting circuits, and performance modification wiring all require professional-grade protection to ensure long-term reliability. The fabric construction provides the durability needed for installations that may be subject to frequent service or modification while maintaining the aesthetic appeal important in custom applications.

Commercial vehicle applications place additional demands on wire protection systems due to extended operating cycles and harsh environmental conditions. Fleet maintenance operations rely on the durability and reliability of this fabric harness tape to minimize electrical system failures and reduce maintenance requirements. The waterproof acrylic adhesive proves particularly valuable in applications where wire bundles may be exposed to washing operations or road splash conditions.

Marine automotive applications, including boat trailers and amphibious vehicles, benefit significantly from the waterproof protection and corrosion resistance engineered into this fabric wrap system. The ability to maintain adhesion and protection in high-humidity environments makes it suitable for applications where traditional tapes may fail due to moisture-related adhesive degradation.

Quality Control & Compliance

Manufacturing processes for this automotive fabric harness tape incorporate comprehensive quality control measures to ensure consistent performance across all production batches. Raw material testing verifies that fabric substrates and adhesive formulations meet specified performance criteria before entering the manufacturing process. In-process monitoring includes adhesion testing, dimensional verification, and visual inspection to maintain product quality throughout production.

Environmental testing protocols evaluate the tape's performance under conditions that simulate actual automotive operating environments. Heat cycling tests verify thermal stability while moisture exposure tests confirm waterproof performance. Vibration testing ensures that the adhesive bond remains secure under the dynamic conditions typical of vehicle operation. These testing procedures validate the product's suitability for demanding automotive applications.

Compliance with automotive industry standards ensures compatibility with existing manufacturing processes and quality systems. The tape formulation avoids materials that could contribute to vehicle emissions or create compatibility issues with automotive substrates. Documentation packages include technical data sheets, safety information, and application guidelines to support professional installation and quality assurance programs.

Customization & Branding Options

Private label manufacturing capabilities enable distributors and automotive suppliers to offer this fabric harness tape under their own branding while maintaining the high performance standards of the base product. Custom packaging options include roll sizes tailored to specific application requirements and packaging formats that align with existing product lines. Color customization allows the tape appearance to match specific automotive manufacturer requirements or aftermarket application preferences.

Technical specification modifications can accommodate unique application requirements while maintaining the core performance characteristics that make this tape suitable for automotive use. Adhesive formulation adjustments may address specific substrate compatibility requirements or environmental conditions not covered by the standard product specification. Width and length customization options provide flexibility for applications requiring non-standard dimensions.

Application-specific packaging solutions include dispenser-compatible formats for high-volume installation environments and bulk packaging for manufacturing applications. Custom documentation and technical support materials can be developed to support specific market requirements or application training programs. These customization capabilities make the fabric harness tape suitable for integration into diverse automotive supply chains and application scenarios.

Packaging & Logistics Support

Professional packaging systems protect the fabric harness tape during storage and transportation while facilitating efficient handling in automotive manufacturing and service environments. Moisture-resistant packaging prevents premature adhesive activation and maintains product quality during extended storage periods. Temperature-stable packaging materials ensure that thermal cycling during transportation does not affect tape performance characteristics.

Logistics support includes consolidation services that enable efficient shipping of mixed product orders and inventory management systems that help maintain optimal stock levels. Distribution partnerships provide regional availability to minimize transportation costs and delivery times for automotive customers. Packaging formats accommodate both small-quantity service applications and large-volume manufacturing requirements.

Supply chain management systems ensure consistent product availability while maintaining the quality standards essential for automotive applications. Inventory tracking capabilities provide visibility into stock levels and enable proactive replenishment planning. Emergency supply protocols can address urgent requirements that may arise during vehicle production or critical service applications.

Why Choose Us

Our organization brings extensive experience in developing specialized automotive adhesive solutions for global markets, with a proven track record of supporting major automotive manufacturers and aftermarket suppliers worldwide. This international market presence provides deep understanding of diverse application requirements and regulatory environments, enabling us to deliver solutions that meet the specific needs of automotive professionals across different regions and market segments.

Collaboration with automotive industry partners has refined our understanding of the performance requirements that distinguish professional-grade products from standard alternatives. This expertise extends across multiple automotive sectors, from passenger vehicle manufacturing to commercial fleet applications, ensuring that our fabric harness tape solutions address the full spectrum of automotive wire protection requirements. Our commitment to continuous improvement drives ongoing product development initiatives that anticipate evolving automotive technology demands.

Quality assurance programs incorporate feedback from automotive professionals to continuously refine product performance and application characteristics. Technical support capabilities include application engineering assistance and product training programs that help customers achieve optimal installation results. Our comprehensive approach to customer support ensures that the 25M Single-Sided Auto Wiring Fabric Wrap Harness Bundle Insulation Heat-Resistant Waterproof Acrylic Adhesive Sticker Cloth harness tape delivers maximum value in real-world automotive applications.

Conclusion

The 25M Single-Sided Auto Wiring Fabric Wrap Harness Bundle Insulation Heat-Resistant Waterproof Acrylic Adhesive Sticker Cloth harness tape represents a comprehensive solution for professional automotive wire protection applications. Its combination of heat resistance, waterproof performance, and flexible fabric construction addresses the demanding requirements of modern automotive electrical systems while providing the reliability essential for both manufacturing and service applications. The advanced acrylic adhesive system ensures secure installation across diverse automotive substrates while maintaining the removability required for service access. This fabric harness tape delivers the performance, durability, and quality that automotive professionals require for protecting critical vehicle wiring systems in challenging operating environments.

| item | value |

| Adhesive | Acrylic |

| Use | MASKING |

| Place of Origin | China |

| Adhesive Side | Single Sided |

| Material | Cloth |

| Type | Adhesive Sticker |

| Thickness | 0.26mm |

| Adhesive Type | Pressure Sensitive |

| Feature | Heat-resistant |

| Brand Name | YLW |

| Model Number | YLW-- B005 |

| Design Printing | No printing |

| cycle length | 25m |

| paper core | No paper core. |

| Printing Handling | No printing |

| glue | Acrylic |

well

1. who are we?

We are based in Jiangsu, China, start from 2025,sell to Mid East(30.00%),Southeast Asia(20.00%),Central America(20.00%),North America(15.00%),South Asia(15.00%). There are total about - people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

automotive tape

4. why should you buy from us not from other suppliers?

-

5. what services can we provide?

Accepted Delivery Terms: -;

Accepted Payment Currency: -;

Accepted Payment Type: -;

Language Spoken: English