Introduction

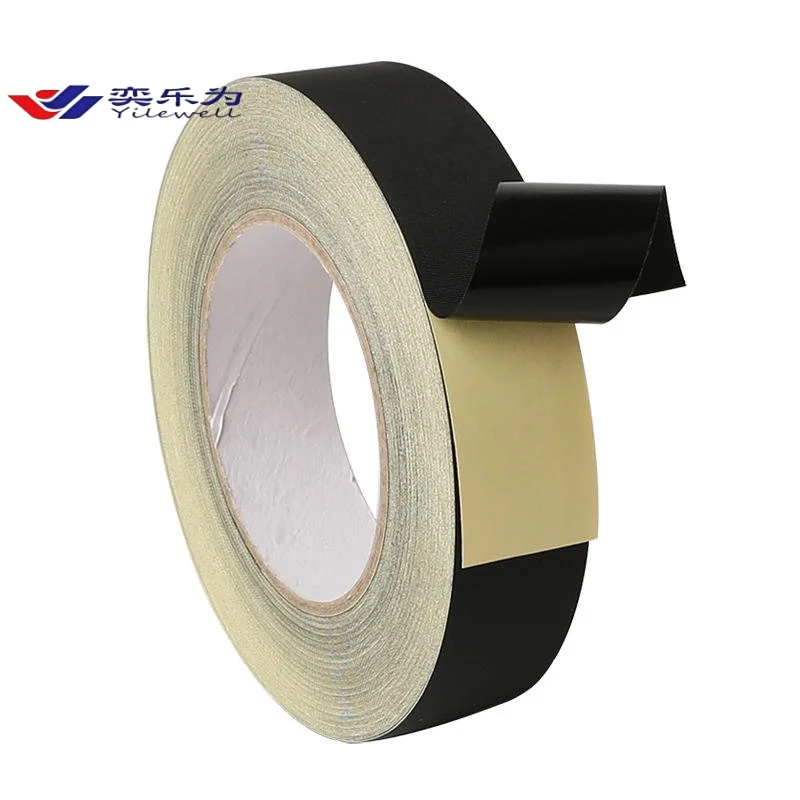

In today's demanding industrial landscape, specialized adhesive solutions play a crucial role in ensuring operational safety and efficiency across multiple sectors. Professional-grade insulation tapes have become indispensable components in electrical applications, automotive manufacturing, and various industrial processes where flame resistance and reliable masking capabilities are paramount. The Black Orange Flame Retardant Flannel (Material) Single Sided Insulation Tape-Masking Use 0.3mm Thickness Pressure Sensitive represents a sophisticated adhesive solution engineered to meet the stringent requirements of modern industrial applications.

This specialized flannel-based insulation tape combines advanced flame retardant properties with superior pressure-sensitive adhesion, delivering exceptional performance in environments where both thermal protection and precise masking are essential. The distinctive black and orange coloration provides excellent visibility during application while maintaining professional aesthetics in finished assemblies. As industries continue to prioritize safety standards and operational efficiency, this flame retardant flannel tape emerges as a critical component for professionals seeking reliable insulation and masking solutions.

Product Overview

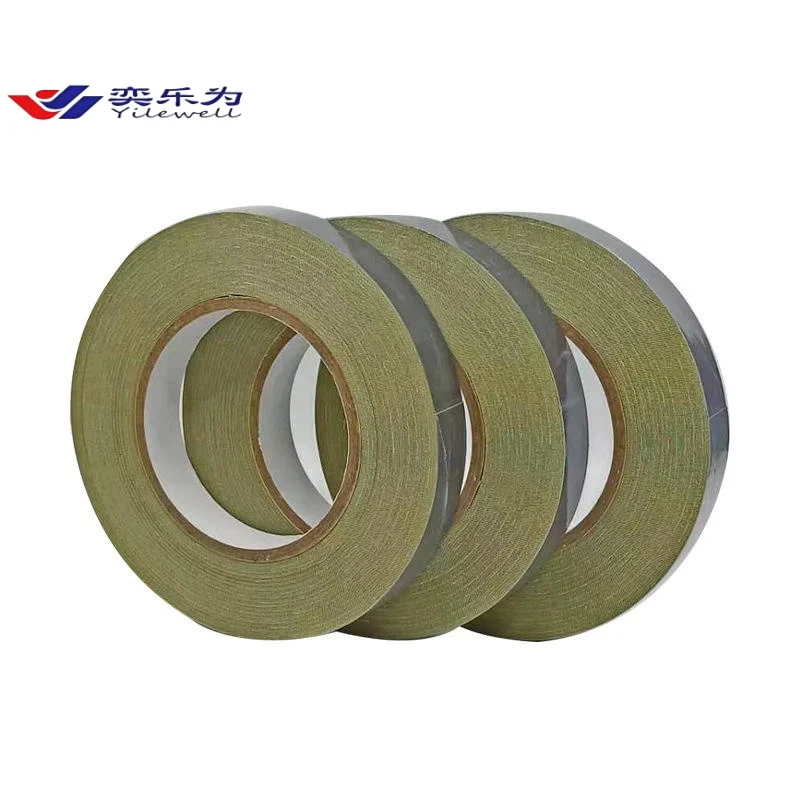

The Black Orange Flame Retardant Flannel (Material) Single Sided Insulation Tape-Masking Use 0.3mm Thickness Pressure Sensitive features a carefully engineered construction that balances flexibility, durability, and thermal protection. The flannel material base provides exceptional conformability around irregular surfaces while maintaining structural integrity under various operating conditions. This single-sided configuration offers precise application control, allowing technicians to achieve exact positioning and coverage in complex assemblies.

The pressure-sensitive adhesive system has been formulated to deliver immediate bond strength upon contact while maintaining removability when required for temporary masking applications. The moderate thickness profile ensures the tape can accommodate surface irregularities without compromising the overall assembly profile. The flame retardant properties integrated throughout the material structure provide consistent thermal protection, making this tape suitable for applications where fire safety compliance is mandatory.

Manufacturing consistency ensures uniform performance characteristics across production runs, enabling reliable specification matching for large-scale industrial applications. The tape's construction methodology incorporates quality control measures that maintain dimensional stability and adhesive performance throughout extended storage periods and varying environmental conditions.

Features & Benefits

Advanced Flame Retardant Technology

The integrated flame retardant system within this flannel insulation tape provides superior fire resistance compared to conventional masking tapes. The chemical composition has been optimized to self-extinguish when exposed to ignition sources, significantly reducing fire propagation risk in electrical and mechanical applications. This enhanced safety profile makes the tape particularly valuable in environments where heat generation or electrical arcing may occur during normal operations.

Unlike standard flame retardant treatments that may compromise adhesive performance, this tape maintains consistent bonding strength while delivering reliable thermal protection. The flame retardant properties remain stable throughout the tape's service life, ensuring long-term safety compliance without degradation of protective characteristics.

Superior Pressure-Sensitive Adhesion

The specialized pressure-sensitive adhesive formulation provides immediate activation upon contact, eliminating the need for heat or solvent activation. This characteristic enables rapid application in production environments where efficiency is critical. The adhesive maintains consistent performance across a wide temperature range, ensuring reliable bonding in both ambient and elevated temperature applications.

The single-sided configuration allows for precise placement and repositioning during initial application while developing full bond strength over time. This feature proves particularly valuable in masking applications where exact boundaries must be maintained throughout processing operations.

Flannel Material Advantages

The flannel base material offers unique advantages in industrial applications, including excellent conformability around curved surfaces and exceptional tear resistance during application and removal. The material's inherent flexibility allows the tape to accommodate thermal expansion and contraction without losing adhesion or developing stress concentrations that could compromise performance.

The flannel construction also provides superior puncture resistance compared to film-based alternatives, making it ideal for applications where mechanical protection is required alongside insulation properties. The material's structure maintains integrity when subjected to vibration or mechanical stress, ensuring long-term reliability in demanding environments.

Applications & Use Cases

The Black Orange Flame Retardant Flannel (Material) Single Sided Insulation Tape-Masking Use 0.3mm Thickness Pressure Sensitive serves diverse industrial applications where both insulation and masking capabilities are required. In electrical manufacturing, this tape provides essential insulation between conductive components while offering flame retardant protection in transformer assemblies, motor windings, and cable harnesses. The tape's conformability makes it particularly suitable for wrapping irregular shapes and creating reliable electrical barriers in compact assemblies.

Automotive manufacturing processes benefit significantly from this tape's dual functionality, particularly in electronic control module assembly and wiring harness production. The flame retardant properties ensure compliance with automotive safety standards while the masking capabilities enable precise coating and finishing operations. The tape's resistance to automotive fluids and temperature variations makes it suitable for under-hood applications where environmental durability is essential.

Industrial equipment manufacturing utilizes this specialized tape for motor protection, control panel assembly, and component masking during powder coating or painting processes. The tape's ability to withstand elevated temperatures encountered in curing ovens while maintaining clean removal characteristics makes it invaluable for finishing operations. Heavy machinery assembly benefits from the tape's mechanical durability and electrical insulation properties in hydraulic system integration and electrical component protection.

Electronics manufacturing processes employ this flame retardant flannel tape for component protection during wave soldering, selective coating applications, and thermal processing. The tape's thermal stability ensures consistent performance throughout manufacturing processes while providing the precision masking required for miniaturized electronic assemblies.

Quality Control & Compliance

Manufacturing excellence forms the foundation of this flame retardant flannel tape's consistent performance characteristics. Comprehensive quality control protocols ensure every production batch meets established specifications for adhesive strength, flame resistance, and dimensional accuracy. Raw material verification processes guarantee that both the flannel substrate and pressure-sensitive adhesive components meet stringent quality standards before entering the production process.

Environmental testing validates the tape's performance under various operating conditions, including temperature cycling, humidity exposure, and chemical resistance evaluation. These comprehensive testing protocols ensure reliable performance across the intended application range while identifying potential limitations that users should consider during specification development.

Flame retardant compliance testing follows established industry standards to verify the tape's fire resistance characteristics. Regular testing maintains certification compliance while ensuring batch-to-batch consistency in flame retardant performance. Documentation systems track all testing results, providing traceability and quality assurance for customers requiring detailed performance verification.

International quality management systems guide production processes, ensuring consistent manufacturing practices that meet global standards for industrial adhesive products. Continuous improvement initiatives incorporate customer feedback and technological advances to enhance product performance while maintaining established reliability standards.

Customization & Branding Options

Understanding that diverse industrial applications require specific performance characteristics, customization capabilities enable tailored solutions that meet unique operational requirements. Core conversion services can modify roll dimensions and packaging configurations to optimize handling and application efficiency in specific production environments. These modifications maintain the fundamental performance characteristics while enhancing usability for particular applications.

Adhesive formulation adjustments can accommodate special bonding requirements or environmental conditions beyond standard specifications. Temperature resistance enhancement, chemical compatibility modifications, and specialized release characteristics represent common customization options that extend the tape's application range. These modifications undergo comprehensive testing to ensure performance consistency and compatibility with existing quality standards.

Private labeling services enable distributors and equipment manufacturers to incorporate their branding while maintaining product integrity and performance standards. Custom packaging solutions can include specialized dispensing systems, protective packaging, and application guides tailored to specific customer requirements. These branding options support customer marketing initiatives while ensuring end-users receive comprehensive product information.

Technical documentation customization provides application-specific installation guides, performance data sheets, and compatibility information that supports customer engineering and procurement processes. This documentation service ensures proper product selection and application while minimizing the risk of performance issues in critical applications.

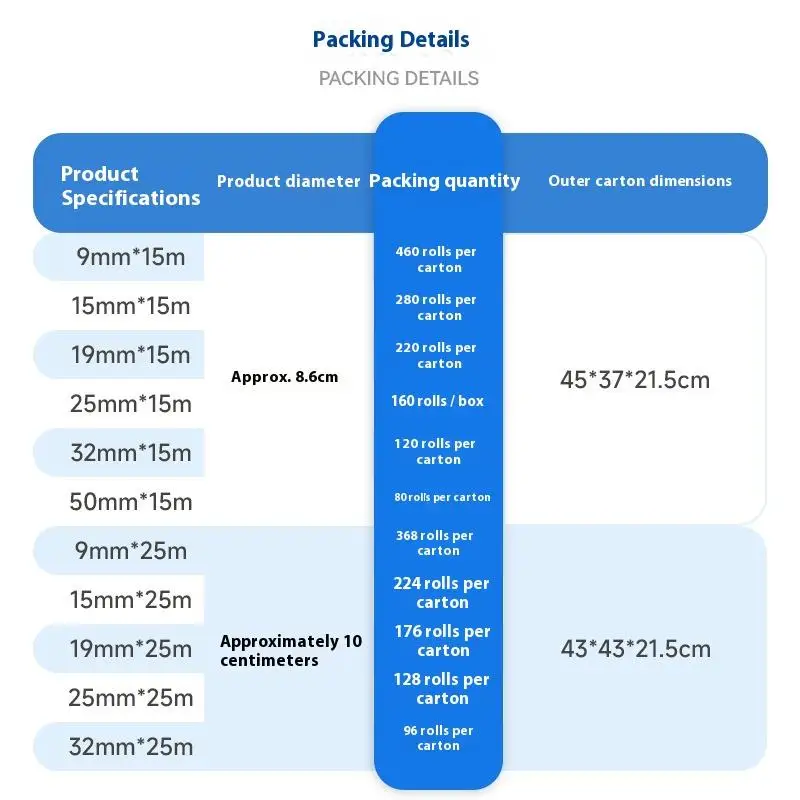

Packaging & Logistics Support

Professional packaging systems protect the Black Orange Flame Retardant Flannel (Material) Single Sided Insulation Tape-Masking Use 0.3mm Thickness Pressure Sensitive during transportation and storage while maintaining product integrity throughout the distribution process. Moisture barrier packaging prevents environmental contamination that could affect adhesive performance, while protective cushioning systems minimize mechanical damage during handling and shipping operations.

Roll core specifications ensure compatibility with standard dispensing equipment while providing structural support during unwinding operations. Core materials are selected for dimensional stability and compatibility with automated application systems commonly used in industrial environments. Packaging configurations accommodate both manual application requirements and automated dispensing system integration.

Inventory management support includes batch coding systems that enable traceability throughout the supply chain while facilitating rotation procedures that maintain product freshness. Temperature-controlled storage recommendations ensure optimal performance characteristics are maintained from manufacturing through end-use application. Documentation systems provide comprehensive product information that supports customer inventory management and quality control procedures.

Global distribution capabilities ensure reliable product availability across international markets while maintaining consistent quality standards. Regional distribution centers minimize delivery times while providing local technical support for application questions and product optimization. Logistics partnerships enable flexible shipping options that accommodate both routine inventory replenishment and emergency supply requirements.

Why Choose Us

Our company has established itself as a trusted metal packaging manufacturer and specialized adhesive solutions provider through decades of international market presence and continuous innovation in industrial material applications. This extensive experience in serving diverse manufacturing sectors has developed deep understanding of customer requirements and application challenges across multiple industries. Our collaboration with global partners demonstrates our commitment to delivering consistent quality and reliable supply chain performance.

Technical expertise in flame retardant materials and pressure-sensitive adhesive formulation enables us to provide comprehensive application support beyond basic product supply. Our engineering team works closely with customers to optimize tape selection and application procedures, ensuring maximum performance in specific operating environments. This consultative approach has established long-term partnerships with leading manufacturers who value both product quality and technical support capabilities.

As a recognized custom tin box supplier and OEM tin packaging solutions provider, our manufacturing capabilities extend beyond adhesive tapes to include comprehensive packaging and material handling solutions. This diverse expertise enables integrated supply chain support that simplifies procurement processes while ensuring compatibility between different material components. Our metal packaging supplier credentials demonstrate the quality management systems and international compliance standards that govern all our manufacturing operations.

Investment in advanced manufacturing technology and quality control systems ensures consistent product performance while enabling rapid response to changing market requirements. Our commitment to continuous improvement incorporates customer feedback and emerging industry standards to enhance both product performance and service capabilities. This forward-thinking approach positions us as a reliable partner for companies seeking long-term supply chain stability and technical innovation.

Conclusion

The Black Orange Flame Retardant Flannel (Material) Single Sided Insulation Tape-Masking Use 0.3mm Thickness Pressure Sensitive represents a sophisticated solution for industrial applications requiring both electrical insulation and flame retardant protection. Its unique combination of flannel-based construction, pressure-sensitive adhesive technology, and integrated fire resistance creates exceptional value for manufacturers across automotive, electronics, and industrial equipment sectors. The tape's ability to provide reliable masking capabilities alongside safety compliance makes it an essential component for companies prioritizing both operational efficiency and workplace safety standards. Through comprehensive quality control, customization capabilities, and technical support services, this specialized tape delivers the performance consistency and application flexibility that modern manufacturing operations demand.

| item | value |

| Adhesive | Acrylic |

| Use | MASKING |

| Place of Origin | China |

| Adhesive Side | Single Sided |

| Material | Flannel |

| Type | Insulation Tape |

| Thickness | 0.3mm |

| Adhesive Type | Pressure Sensitive |

| Feature | Heat-resistant |

| Brand Name | YLW |

| Model Number | YLW-R001 |

| Design Printing | Offer Printing |

| cycle length | 10m |

| paper core | Customizable |

| Printing Handling | Offer printing |

| glue | Acrylic |

well

1. who are we?

We are based in Jiangsu, China, start from 2025,sell to Mid East(30.00%),Southeast Asia(20.00%),Central America(20.00%),North America(15.00%),South Asia(15.00%). There are total about - people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

automotive tape

4. why should you buy from us not from other suppliers?

-

5. what services can we provide?

Accepted Delivery Terms: -;

Accepted Payment Currency: -;

Accepted Payment Type: -;

Language Spoken: English