Introduction

In the demanding world of automotive manufacturing and maintenance, proper wire harness management stands as a critical component for ensuring vehicle safety and performance. The Car Engine Wire Harness Strapping Tape Acrylic Adhesive Single-Sided Cloth Masking Heat-resistant Wear-Resistant 25m Length represents a professional-grade solution designed to meet the stringent requirements of modern automotive applications. This specialized adhesive tape combines advanced materials engineering with practical functionality, delivering exceptional performance in high-temperature environments where traditional taping solutions often fail.

Automotive professionals worldwide recognize the importance of reliable wire harness protection systems that can withstand the harsh conditions found in engine compartments. This premium cloth-based strapping tape addresses these challenges through its unique combination of heat resistance, wear durability, and superior adhesion properties. Whether used in original equipment manufacturing or aftermarket repair applications, this product provides the dependable performance that automotive technicians and engineers demand.

Product Overview

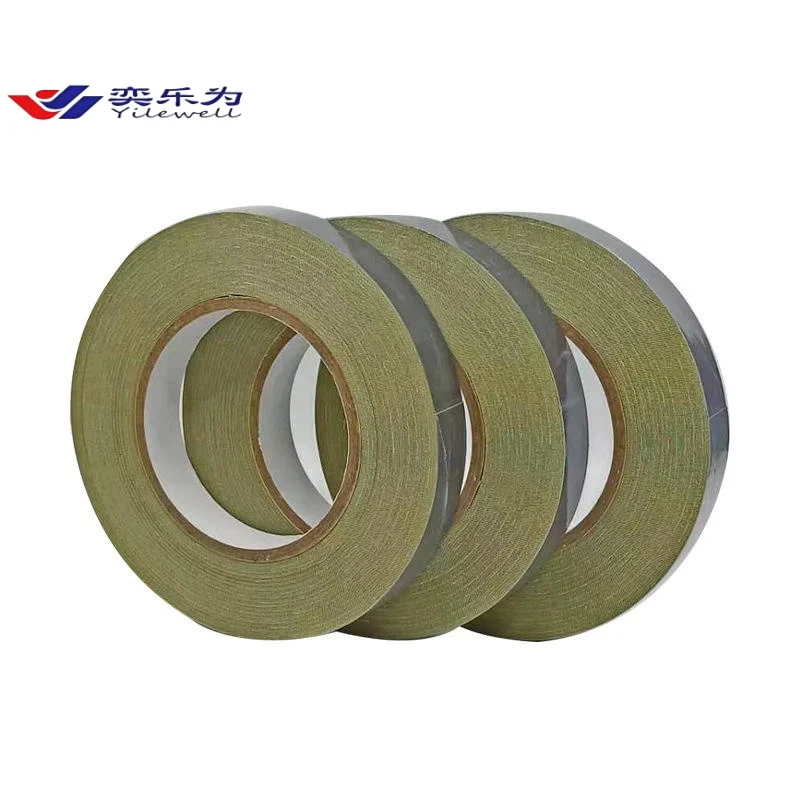

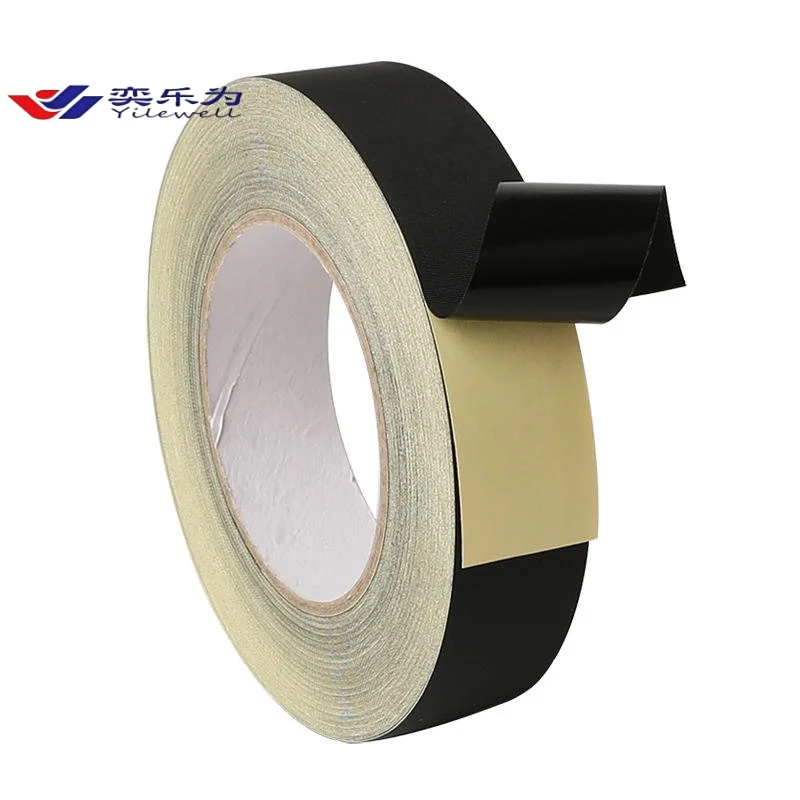

The Car Engine Wire Harness Strapping Tape Acrylic Adhesive Single-Sided Cloth Masking Heat-resistant Wear-Resistant 25m Length features a sophisticated construction that incorporates multiple layers of specialized materials. The cloth backing provides exceptional tensile strength and conformability, allowing the tape to wrap securely around complex wire harness configurations while maintaining its integrity under mechanical stress. The acrylic adhesive system has been specifically formulated to deliver consistent bonding performance across a wide range of temperatures and environmental conditions.

This single-sided adhesive configuration offers optimal versatility for various application methods, enabling technicians to achieve secure wire bundling and protection with minimal preparation time. The extended length format ensures adequate coverage for comprehensive wire harness projects while reducing the frequency of roll changes during installation procedures. The cloth substrate's inherent flexibility and tear resistance make this tape particularly suitable for applications involving vibration, thermal cycling, and mechanical movement.

Features & Benefits

Advanced Heat Resistance Technology

The heat-resistant properties of this strapping tape stem from careful selection of both the cloth backing material and the acrylic adhesive formulation. Unlike conventional tapes that may deteriorate or lose adhesion when exposed to elevated temperatures, this product maintains its structural integrity and bonding strength throughout the temperature ranges commonly encountered in automotive engine compartments. The thermal stability ensures long-term reliability and reduces the need for frequent maintenance or replacement cycles.

Superior Wear Resistance

Wear resistance represents another critical advantage of this cloth-based tape system. The robust construction withstands abrasion from vibration, contact with engine components, and general handling during installation and service procedures. This durability translates into extended service life and reduced maintenance costs for automotive applications where wire harness protection must remain effective over extended periods of operation.

Optimal Adhesive Performance

The acrylic adhesive system provides excellent initial tack combined with long-term holding power. This balanced adhesive performance ensures secure installation without the aggressive bonding characteristics that can make removal difficult during service procedures. The single-sided configuration allows for controlled application and repositioning when necessary, while still delivering the permanent bonding strength required for demanding automotive environments.

Applications & Use Cases

Automotive wire harness applications represent the primary use case for this specialized strapping tape, encompassing everything from engine bay installations to chassis wiring systems. The product excels in securing wire bundles against vibration, protecting cables from heat exposure, and organizing complex wiring layouts for improved serviceability. Professional technicians rely on this tape for both original equipment manufacturing processes and aftermarket repair work where reliable wire management is essential.

Beyond traditional automotive applications, this heat-resistant cloth tape finds utility in industrial equipment installations, marine electrical systems, and aerospace wiring projects where similar environmental challenges exist. The combination of thermal stability, mechanical durability, and chemical resistance makes it suitable for harsh operating conditions across multiple industries. Manufacturing facilities utilize this product for production line applications where consistent performance and quality are paramount.

Maintenance and repair operations benefit significantly from the tape's reliable performance characteristics. Service technicians appreciate the balance between secure adhesion and removability, which facilitates both permanent installations and temporary repairs. The cloth backing's conformability allows for effective wrapping around irregular shapes and complex geometries commonly encountered in modern vehicle designs.

Quality Control & Compliance

Manufacturing excellence drives the production process for this automotive-grade strapping tape, with comprehensive quality control measures ensuring consistent performance across every production batch. Advanced testing protocols evaluate adhesive strength, temperature resistance, and mechanical properties to verify compliance with automotive industry standards. The manufacturing facility maintains strict environmental controls during production to ensure optimal curing conditions and material integrity.

Raw material selection follows rigorous qualification procedures, with incoming inspection protocols verifying that both cloth substrates and adhesive components meet specified performance criteria. Quality assurance testing includes accelerated aging studies that simulate long-term exposure to automotive operating conditions, ensuring that the finished product will deliver reliable performance throughout its intended service life.

Traceability systems track each production lot from raw material receipt through final packaging, enabling rapid response to any quality concerns and supporting continuous improvement initiatives. Regular third-party testing validates conformance to industry standards and provides independent verification of product performance claims.

Customization & Branding Options

Recognizing the diverse needs of automotive manufacturers and distributors, comprehensive customization capabilities accommodate specific application requirements and branding preferences. Width variations, adhesive formulations, and backing materials can be modified to address unique performance specifications or installation constraints. Custom printing options allow for product identification, safety warnings, or brand messaging directly on the tape surface.

Private labeling services enable distributors and resellers to market this professional-grade strapping tape under their own brand identity while maintaining the underlying quality and performance standards. Packaging customization includes options for roll sizes, protective wrapping materials, and labeling formats that align with customer distribution requirements and end-user preferences.

Technical consultation services support customers in optimizing tape specifications for their particular applications, drawing on extensive experience in automotive wire harness management and adhesive technology. This collaborative approach ensures that customized products deliver maximum value and performance for specific use cases while maintaining the reliability and quality that professional users demand.

Packaging & Logistics Support

Professional packaging solutions protect this sensitive adhesive product during storage and transportation while facilitating efficient handling in distribution and end-use environments. Moisture barrier packaging prevents premature aging of the acrylic adhesive system, while sturdy outer containers protect against physical damage during shipping and warehousing operations. Clear labeling and product identification support inventory management and ensure proper product selection.

Flexible shipping configurations accommodate various order sizes and delivery requirements, from individual rolls for small repair operations to bulk quantities for manufacturing applications. Packaging optimization balances protection requirements with shipping efficiency, minimizing transportation costs while ensuring product integrity upon delivery.

International shipping expertise facilitates global distribution with proper documentation and compliance with import regulations across multiple markets. Consolidation services enable efficient ordering for customers requiring multiple product variants or complementary items, reducing logistics complexity and associated costs.

Why Choose Us

Our organization brings over two decades of specialized experience in automotive adhesive solutions to the global marketplace, serving customers across North America, Europe, and Asia-Pacific regions. This extensive international presence enables us to understand and respond to the diverse requirements of automotive manufacturers, distributors, and service providers worldwide. Our commitment to innovation and quality has established strong partnerships with leading automotive companies who rely on our products for their most demanding applications.

As a recognized metal packaging supplier and custom tin box supplier, we understand the importance of reliable protection solutions across multiple industries. This cross-industry expertise enhances our ability to develop and manufacture adhesive products that meet the highest standards for automotive applications while leveraging advanced materials and manufacturing techniques proven in other demanding sectors.

Continuous investment in research and development ensures that our Car Engine Wire Harness Strapping Tape Acrylic Adhesive Single-Sided Cloth Masking Heat-resistant Wear-Resistant 25m Length incorporates the latest advances in adhesive technology and materials science. Our technical team collaborates closely with automotive engineers and technicians to identify emerging requirements and develop solutions that address evolving industry needs. This proactive approach to product development has resulted in numerous innovations that have set new standards for performance and reliability in automotive wire harness applications.

Conclusion

The Car Engine Wire Harness Strapping Tape Acrylic Adhesive Single-Sided Cloth Masking Heat-resistant Wear-Resistant 25m Length represents the convergence of advanced materials engineering and practical automotive application requirements. Its exceptional combination of heat resistance, wear durability, and reliable adhesion makes it an indispensable tool for automotive professionals who demand consistent performance in challenging environments. The product's versatility extends beyond traditional automotive applications, serving diverse industries where robust wire management solutions are essential. Through comprehensive quality control, customization capabilities, and global logistics support, this professional-grade strapping tape delivers the reliability and performance that modern automotive applications require. The investment in superior materials and manufacturing processes ensures that users receive maximum value through extended service life, reduced maintenance requirements, and consistent performance across varying operating conditions.

| item | value |

| Adhesive | Acrylic |

| Use | MASKING |

| Place of Origin | China |

| Adhesive Side | Single Sided |

| Material | Cloth |

| Type | Adhesive Sticker |

| Thickness | 0.26mm |

| Adhesive Type | Pressure Sensitive |

| Feature | Heat-resistant |

| Brand Name | YLW |

| Model Number | YLW-- B005 |

| Design Printing | No printing |

| cycle length | 25m |

| paper core | No paper core. |

| Printing Handling | No printing |

| glue | Acrylic |

well

1. who are we?

We are based in Jiangsu, China, start from 2025,sell to Mid East(30.00%),Southeast Asia(20.00%),Central America(20.00%),North America(15.00%),South Asia(15.00%). There are total about - people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

automotive tape

4. why should you buy from us not from other suppliers?

-

5. what services can we provide?

Accepted Delivery Terms: -;

Accepted Payment Currency: -;

Accepted Payment Type: -;

Language Spoken: English