Introduction

In today's demanding industrial landscape, professionals across automotive, electronics, and manufacturing sectors require reliable adhesive solutions that deliver consistent performance under challenging conditions. The Cloth Masking TapePressure Sensitive Acrylic Adhesive Single Sided Heat Resistant No Residue 25m Length harness tape represents a breakthrough in industrial adhesive technology, engineered specifically for applications where precision, durability, and clean removal are paramount. This specialized tape combines the strength of woven cloth backing with advanced acrylic adhesive chemistry, creating a solution that excels in high-temperature environments while maintaining exceptional bonding characteristics.

Developed through extensive research and testing, this professional-grade masking tape addresses the critical needs of modern manufacturing processes where traditional adhesive products often fall short. Whether protecting sensitive components during powder coating, securing wire harnesses in automotive assemblies, or providing temporary masking in electronic device manufacturing, this innovative tape solution delivers the reliability and performance that quality-conscious professionals demand.

Product Overview

The Cloth Masking TapePressure Sensitive Acrylic Adhesive Single Sided Heat Resistant No Residue 25m Length harness tape features a sophisticated construction that combines multiple engineered components to achieve superior performance characteristics. The foundation consists of a premium woven cloth backing material that provides exceptional tensile strength and conformability, allowing the tape to follow complex contours and maintain integrity even under mechanical stress.

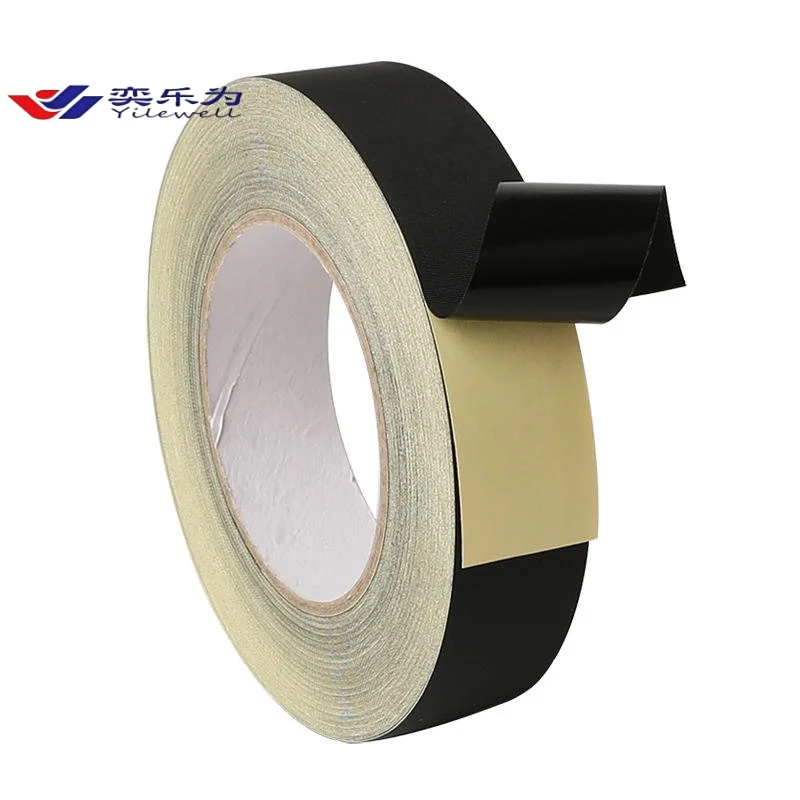

The pressure-sensitive acrylic adhesive system represents years of chemical engineering advancement, formulated to provide immediate tack upon application while maintaining consistent bonding strength across varying temperature ranges. This single-sided configuration ensures precise application control and eliminates the complications associated with double-sided products, making it ideal for masking operations where exact positioning is critical.

Heat resistance capabilities make this harness tape particularly valuable in manufacturing environments where elevated temperatures are encountered during processing operations. The no-residue formula ensures clean removal even after extended exposure periods, protecting substrate surfaces and reducing post-application cleanup requirements. The extended length format provides excellent value and reduces the frequency of roll changes during production operations.

Features & Benefits

Advanced Adhesive Technology

The pressure-sensitive acrylic adhesive system incorporated in this cloth masking tape represents cutting-edge polymer chemistry designed for industrial applications. Unlike conventional rubber-based adhesives that can fail under temperature stress or leave troublesome residues, this acrylic formulation maintains consistent performance characteristics across a wide operational temperature range. The adhesive provides immediate bonding upon contact, eliminating the need for additional pressure or activation time that can slow production processes.

The no-residue properties of this adhesive system are particularly valuable in precision manufacturing environments where substrate cleanliness is critical. After removal, surfaces remain free from adhesive transfer, reducing cleaning requirements and ensuring optimal conditions for subsequent processing steps. This characteristic makes the tape especially suitable for applications involving painted surfaces, delicate electronics, or precision-machined components where contamination cannot be tolerated.

Superior Heat Resistance

Heat resistance capabilities distinguish this harness tape from standard masking products, enabling its use in elevated temperature applications where conventional tapes would fail. The cloth backing material maintains dimensional stability and mechanical properties even when exposed to the thermal cycling common in automotive and electronics manufacturing. This thermal stability ensures that masking boundaries remain precise and that the tape can be removed cleanly even after heat exposure.

The combination of heat-resistant backing and temperature-stable adhesive creates a masking solution that performs reliably in powder coating ovens, electronic component soldering operations, and automotive paint processes. This thermal performance eliminates the need for multiple tape products in facilities that handle both ambient and elevated temperature applications.

Durable Cloth Construction

The woven cloth backing provides mechanical properties that significantly exceed those of paper or film-based masking tapes. This construction offers superior tear resistance, preventing accidental damage during application or removal operations. The fabric structure also provides excellent conformability, allowing the tape to follow irregular surfaces and maintain consistent contact pressure across the bonded area.

Cloth construction contributes to the tape's ability to withstand mechanical stress during manufacturing operations, making it suitable for applications where the masked assembly may be handled, moved, or subjected to vibration. This durability reduces the risk of masking failure that could compromise product quality or require costly rework operations.

Applications & Use Cases

The versatility of this Cloth Masking TapePressure Sensitive Acrylic Adhesive Single Sided Heat Resistant No Residue 25m Length harness tape makes it invaluable across numerous industrial applications. In automotive manufacturing, the tape excels in wire harness assembly operations, providing secure bundling and routing while withstanding the thermal and mechanical stresses encountered in vehicle production. The heat resistance properties make it particularly suitable for under-hood applications where temperature fluctuations are common.

Electronics manufacturing represents another significant application area where this specialized tape delivers exceptional value. Component masking during selective soldering, conformal coating operations, and thermal processing requires an adhesive solution that maintains precise boundaries while resisting elevated temperatures. The no-residue characteristics ensure that sensitive electronic components remain uncontaminated after tape removal, maintaining optimal electrical performance and reliability.

Industrial painting and coating operations benefit significantly from the tape's combination of heat resistance and clean removability. Whether protecting threaded connections during powder coating, masking critical surfaces during spray operations, or creating precise paint lines on complex assemblies, this harness tape delivers the consistency and reliability that professional finishers require. The cloth backing provides excellent edge sealing, preventing paint bleed-through that could compromise finish quality.

General manufacturing applications include temporary component protection, assembly fixturing, and quality control operations. The tape's ability to provide secure adhesion without permanent bonding makes it ideal for holding components in position during machining, welding, or assembly operations. The extended length format reduces interruptions during high-volume production runs, contributing to improved operational efficiency.

Quality Control & Compliance

Manufacturing of this professional-grade cloth masking tape follows rigorous quality control protocols designed to ensure consistent performance characteristics across every production batch. Raw material inspection procedures verify that both the cloth backing and acrylic adhesive components meet established specifications before processing begins. This upstream quality control prevents variations that could affect final product performance in critical applications.

In-process monitoring systems track key parameters including adhesive coating weight, backing thickness uniformity, and adhesive curing conditions. These controls ensure that each roll meets the heat resistance, adhesion strength, and no-residue performance standards that professional users depend upon. Statistical process control methodologies identify trends before they can impact product quality, maintaining the consistency essential for industrial applications.

Final product testing encompasses thermal performance validation, adhesion testing under controlled conditions, and residue evaluation using standardized test substrates. These comprehensive testing procedures verify that each production lot meets performance specifications and provides the reliability required in demanding manufacturing environments. Documentation systems maintain full traceability from raw materials through final packaging, supporting quality investigations when required.

Compliance with relevant industry standards ensures that this harness tape meets the requirements of professional users across multiple sectors. Environmental testing confirms performance stability under varying storage and application conditions, while safety evaluations verify that the product poses no unusual risks during normal handling and use operations.

Customization & Branding Options

Understanding that industrial customers often require specialized solutions, comprehensive customization capabilities accommodate specific application requirements and branding preferences. Width modifications can be provided to match particular masking requirements, while length options ensure optimal fit with production processes and inventory management practices. These dimensional customizations eliminate waste and improve operational efficiency in high-volume applications.

Adhesive formulation adjustments can address unique performance requirements such as enhanced initial tack for difficult-to-bond surfaces or modified temperature resistance for specialized thermal processes. These technical customizations leverage extensive adhesive chemistry expertise to create solutions that exceed standard product capabilities when applications demand enhanced performance.

Private labeling services enable distributors and major end users to incorporate their branding into product packaging and identification systems. Custom printing options include company logos, part numbers, and application-specific information that supports inventory management and quality control procedures. These branding services help establish product identity and support marketing efforts in competitive markets.

Packaging customization addresses specific handling and storage requirements, with options ranging from individual roll packaging to bulk configurations designed for high-volume users. Custom labeling can include application instructions, safety information, and traceability data that supports professional users' quality management systems.

Packaging & Logistics Support

Professional packaging systems protect product integrity during storage and transportation while providing the accessibility required for efficient inventory management. Each roll of this Cloth Masking TapePressure Sensitive Acrylic Adhesive Single Sided Heat Resistant No Residue 25m Length harness tape receives protective wrapping that prevents contamination and adhesive degradation during extended storage periods. The packaging materials are selected to maintain product performance characteristics under varying environmental conditions.

Case packaging configurations accommodate different inventory management approaches, from individual roll requirements to bulk orders for high-volume users. Standardized case dimensions optimize shipping efficiency while protecting individual rolls from handling damage. Clear identification labeling supports accurate inventory tracking and reduces the risk of product mix-ups in busy warehouse environments.

International shipping capabilities ensure reliable delivery to global customers, with packaging designed to withstand the extended transit times and handling conditions associated with international logistics. Documentation packages include all necessary shipping papers, safety data sheets, and technical specifications required for international commerce and customs clearance procedures.

Inventory management support includes flexible order scheduling that accommodates seasonal demand variations and production planning requirements. Logistics coordination helps optimize shipping costs and delivery timing, ensuring that customers receive their orders when needed without excessive inventory carrying costs.

Why Choose Us

With over two decades of experience serving international markets, our company has established itself as a trusted partner for businesses seeking reliable adhesive solutions. Our comprehensive understanding of global manufacturing requirements and quality standards ensures that every product meets the demanding expectations of professional users across diverse industries. This extensive market presence provides valuable insights into emerging application requirements and technology trends.

Our commitment to innovation drives continuous improvement in product formulations and manufacturing processes, resulting in adhesive solutions that consistently exceed industry standards. Collaborative relationships with leading manufacturers worldwide have provided deep insights into real-world application requirements, enabling the development of products that address specific industry challenges. This customer-focused approach ensures that our solutions provide genuine value in professional applications.

As a recognized metal packaging supplier and industrial adhesive manufacturer, our integrated approach to product development leverages expertise across multiple technology areas. This cross-industry knowledge enables unique solutions that combine the best aspects of different technologies to create superior performance products. Our role as a trusted custom packaging solutions provider extends to specialized adhesive applications where standard products cannot meet specific requirements.

Quality management systems meet international standards and support the rigorous requirements of customers in regulated industries. Our global supply chain capabilities ensure consistent product availability while maintaining the cost effectiveness essential for competitive manufacturing operations. Technical support services provide application guidance and troubleshooting assistance, helping customers optimize their use of our products and achieve superior results in their specific applications.

Conclusion

The Cloth Masking TapePressure Sensitive Acrylic Adhesive Single Sided Heat Resistant No Residue 25m Length harness tape represents a significant advancement in industrial adhesive technology, combining superior materials engineering with practical application benefits. Its unique combination of heat resistance, no-residue removal, and durable cloth construction makes it an invaluable tool for professionals across automotive, electronics, and general manufacturing industries. The extensive length format and reliable performance characteristics ensure exceptional value in high-volume production environments where consistency and reliability are paramount. This innovative adhesive solution demonstrates how advanced materials science can address real-world industrial challenges, providing manufacturers with the tools they need to achieve superior results while maintaining operational efficiency and cost effectiveness.

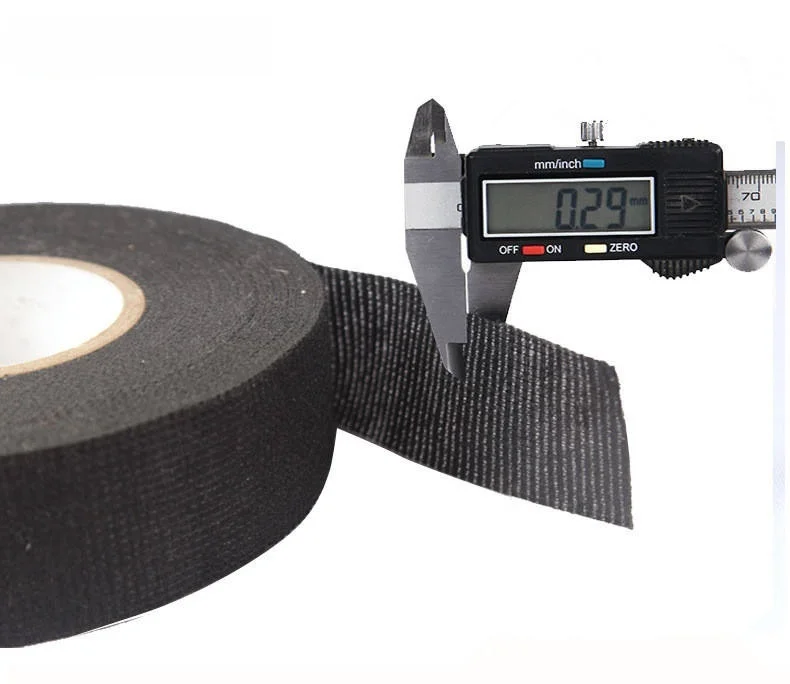

| item | value |

| Adhesive | Acrylic |

| Use | MASKING |

| Place of Origin | China |

| Adhesive Side | Single Sided |

| Material | Cloth |

| Type | Adhesive Sticker |

| Thickness | 0.26mm |

| Adhesive Type | Pressure Sensitive |

| Feature | Heat-resistant |

| Brand Name | YLW |

| Model Number | YLW-- B005 |

| Design Printing | No printing |

| cycle length | 25m |

| paper core | No paper core. |

| Printing Handling | No printing |

| glue | Acrylic |

well

1. who are we?

We are based in Jiangsu, China, start from 2025,sell to Mid East(30.00%),Southeast Asia(20.00%),Central America(20.00%),North America(15.00%),South Asia(15.00%). There are total about - people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

automotive tape

4. why should you buy from us not from other suppliers?

-

5. what services can we provide?

Accepted Delivery Terms: -;

Accepted Payment Currency: -;

Accepted Payment Type: -;

Language Spoken: English