Introduction

Professional automotive wiring applications demand superior insulation materials that can withstand extreme temperatures, chemical exposure, and mechanical stress. The Electrical Insulation Tape Heat-resistant Adhesive Masking Tape 19mm for Car Cable Harness Wiring represents a breakthrough in automotive electrical protection technology, designed specifically for demanding wire harness applications in modern vehicles. This specialized tape combines advanced adhesive chemistry with heat-resistant substrate materials to deliver exceptional performance in automotive environments where traditional insulation materials often fail.

Modern automotive electrical systems have become increasingly complex, requiring insulation solutions that can handle higher operating temperatures, greater electrical loads, and more challenging environmental conditions. This professional-grade electrical insulation tape addresses these evolving needs by providing reliable protection for cable harnesses, wire bundles, and individual conductors throughout the vehicle's electrical network. The tape's engineered construction ensures long-term durability while maintaining excellent electrical insulation properties across a wide temperature range.

Product Overview

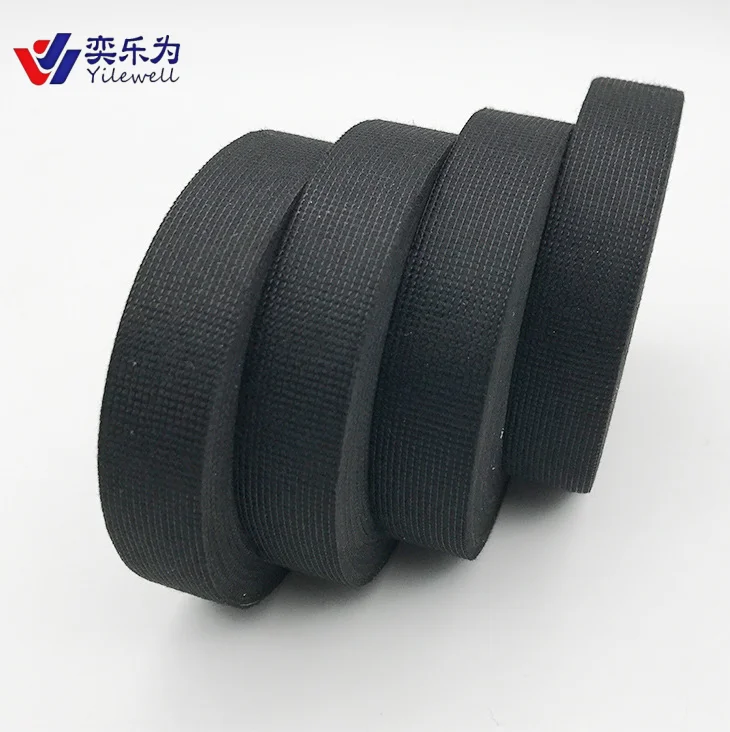

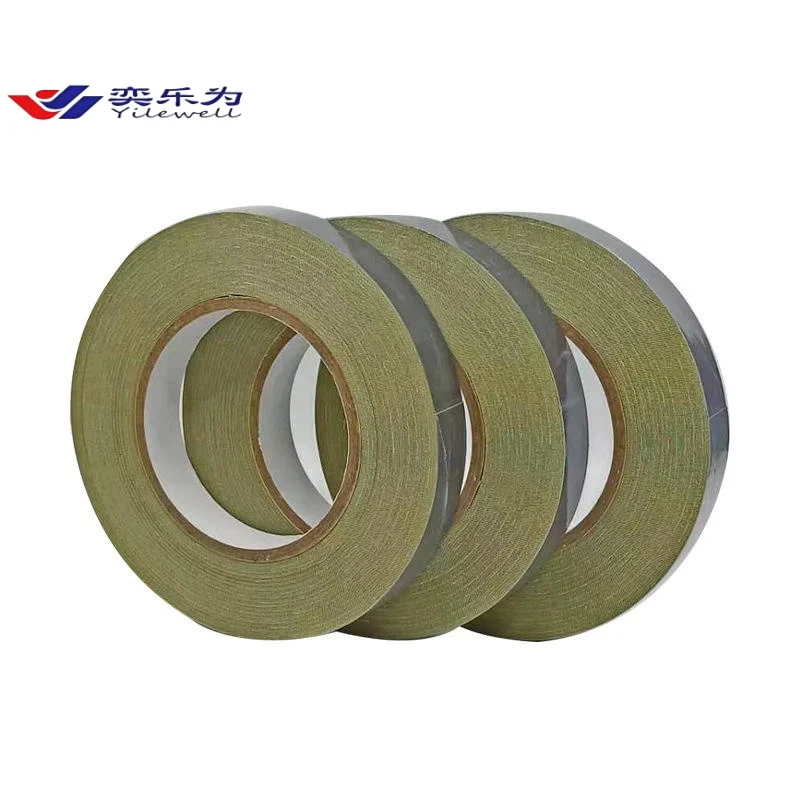

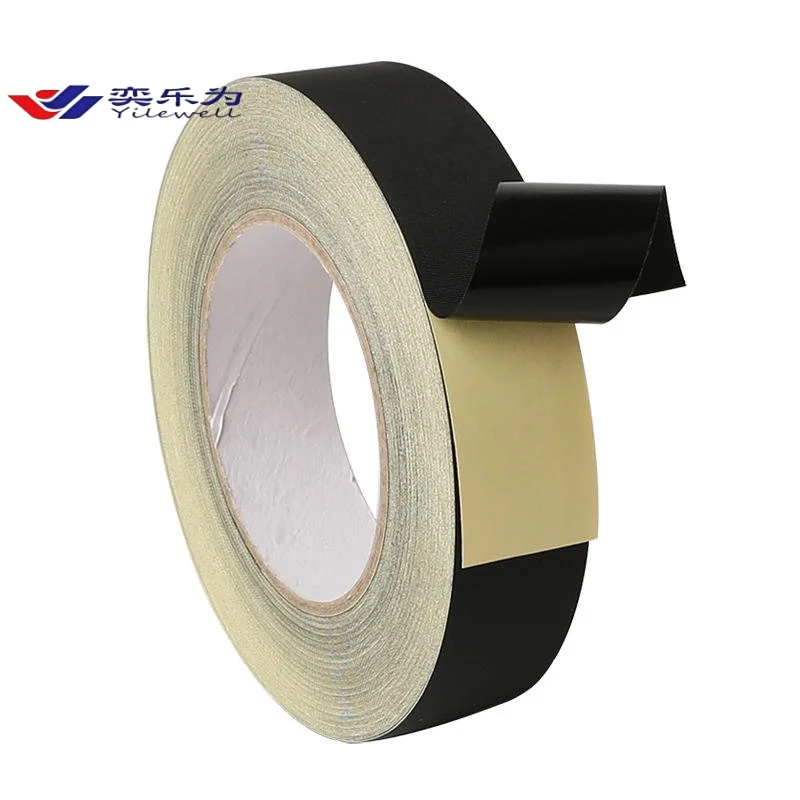

This heat-resistant electrical insulation tape features a carefully engineered multi-layer construction that maximizes performance in automotive applications. The base substrate utilizes advanced polymer technology to provide exceptional thermal stability, while the pressure-sensitive adhesive system ensures secure bonding to various wire types and harness materials commonly found in automotive manufacturing. The tape's uniform thickness and consistent width make it ideal for both manual application and automated production processes.

The specialized adhesive formulation maintains its bonding strength across extreme temperature variations, ensuring that wire harnesses remain properly insulated throughout the vehicle's operational life. Unlike standard electrical tapes that may degrade or lose adhesion under hood temperatures, this heat-resistant solution maintains its protective properties even when exposed to engine compartment conditions. The tape's flexibility allows for easy application around complex wire routing patterns while providing complete coverage of exposed conductors.

Manufacturing quality controls ensure consistent tape dimensions and adhesive performance across every roll, making this product suitable for high-volume automotive production environments. The tape unwinds smoothly and applies evenly, reducing application time while ensuring professional results. Its balanced construction provides the optimal combination of conformability and tensile strength required for demanding automotive harness applications.

Features & Benefits

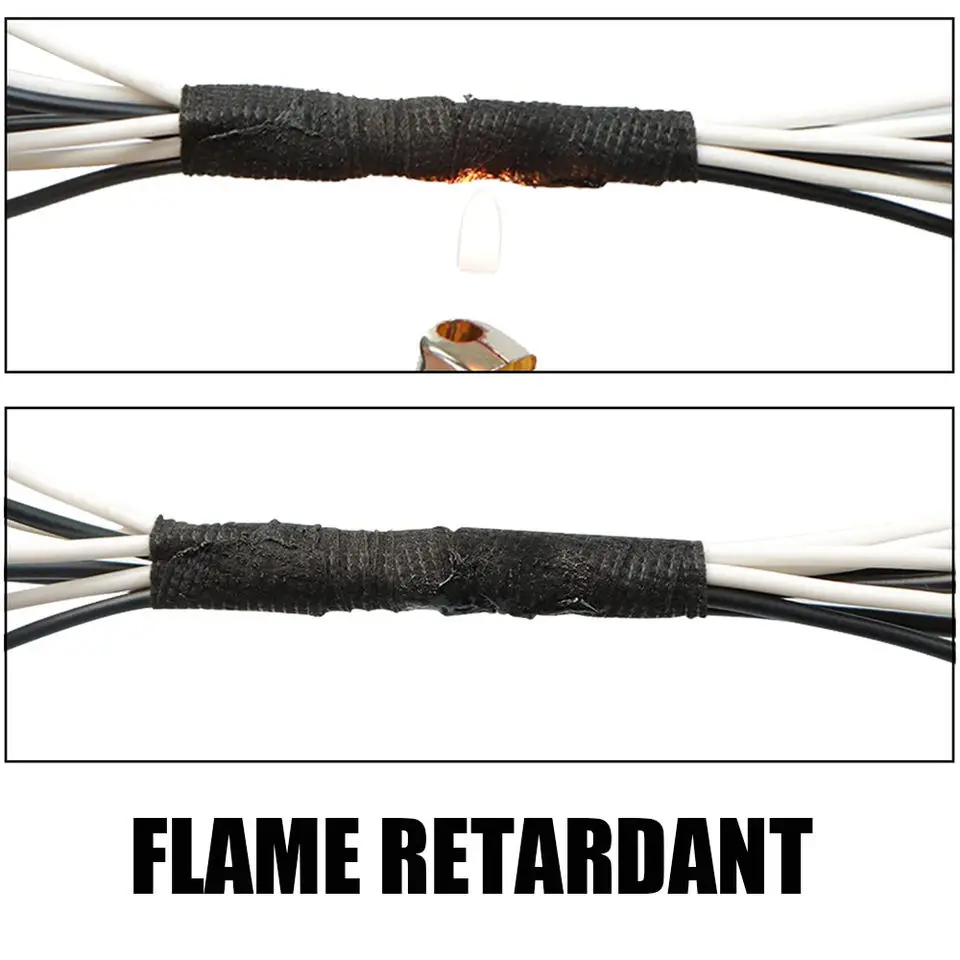

Superior Heat Resistance

The advanced substrate material maintains its structural integrity and electrical insulation properties at elevated temperatures commonly encountered in automotive environments. This exceptional heat resistance prevents tape degradation, adhesive failure, and insulation breakdown that can lead to electrical shorts or system failures. The thermal stability ensures consistent performance whether applied in engine compartments, transmission areas, or other high-temperature automotive zones.

Enhanced Adhesive Performance

The specially formulated pressure-sensitive adhesive creates strong, durable bonds with various wire insulation materials, including PVC, polyethylene, and cross-linked polymers. This versatile adhesion capability eliminates the need for multiple tape types in mixed-material harness assemblies. The adhesive maintains its bonding strength across temperature cycles while resisting automotive fluids, oils, and cleaning solvents commonly encountered during vehicle service.

Electrical Insulation Excellence

Engineered dielectric properties provide reliable electrical isolation between conductors and grounded vehicle components. The tape's consistent thickness and uniform construction eliminate weak points that could compromise insulation integrity. This reliable electrical protection helps prevent short circuits, ground faults, and electromagnetic interference that can affect sensitive automotive electronic systems.

Mechanical Durability

The tape's balanced construction provides excellent resistance to abrasion, puncture, and tear forces encountered during harness installation and vehicle operation. This mechanical durability protects underlying wire insulation from damage during assembly processes and throughout the vehicle's service life. The tape's flexibility allows it to accommodate wire movement and thermal expansion without cracking or separating.

Applications & Use Cases

Automotive cable harness manufacturing represents the primary application for this specialized Electrical Insulation Tape Heat-resistant Adhesive Masking Tape 19mm for Car Cable Harness Wiring. Wire harness manufacturers utilize this tape to secure and insulate branch connections, splice joints, and termination points throughout complex automotive wiring systems. The tape's reliable performance ensures that these critical connection points remain protected throughout the vehicle's operational life, even under demanding environmental conditions.

Engine compartment applications particularly benefit from the tape's heat-resistant properties, where traditional insulation materials often fail due to elevated temperatures and chemical exposure. The tape provides essential protection for ignition system wiring, fuel injection harnesses, and sensor connections that operate in close proximity to hot engine components. Its chemical resistance ensures that exposure to automotive fluids, oils, and cleaning agents does not compromise the insulation integrity.

Transmission and drivetrain wiring applications require insulation materials that can withstand both thermal stress and mechanical vibration. This heat-resistant tape provides the necessary durability to protect speed sensors, solenoid connections, and control module wiring in these challenging environments. The tape's excellent adhesion prevents loosening or separation even under continuous vibration and temperature cycling.

Aftermarket automotive repair and modification applications also benefit from this professional-grade insulation tape. Service technicians and custom installers rely on its superior performance when repairing damaged harnesses, installing additional electrical components, or modifying existing wiring systems. The tape's professional appearance and reliable performance make it suitable for both temporary repairs and permanent installations.

Quality Control & Compliance

Manufacturing processes incorporate comprehensive quality control measures to ensure consistent tape performance and reliability. Each production run undergoes rigorous testing for adhesive strength, electrical insulation properties, and thermal stability to verify compliance with automotive industry standards. These quality controls ensure that every roll of tape meets the demanding performance requirements of modern automotive applications.

Material certification processes verify that all raw materials meet stringent automotive specifications for outgassing, flame resistance, and chemical compatibility. The tape's formulation excludes materials that could contribute to interior air quality issues or interfere with sensitive electronic components. Environmental testing confirms the tape's stability under automotive storage and operating conditions.

Continuous improvement programs monitor field performance and customer feedback to drive product enhancements and manufacturing refinements. This ongoing commitment to quality ensures that the Electrical Insulation Tape Heat-resistant Adhesive Masking Tape 19mm for Car Cable Harness Wiring continues to meet evolving automotive industry requirements. Regular audits of manufacturing facilities and quality systems maintain compliance with international automotive quality standards.

Customization & Branding Options

Professional tape manufacturers understand that automotive OEMs and harness suppliers often require customized solutions to meet specific application requirements or branding preferences. Custom formulations can be developed to address unique performance requirements, such as enhanced chemical resistance for specific automotive fluids or modified adhesive properties for particular substrate materials. These customization capabilities ensure optimal performance in specialized automotive applications.

Private labeling services allow distributors and automotive suppliers to market the tape under their own brand identity while maintaining the underlying product quality and performance. Custom packaging options include branded cores, labels, and protective wrapping that align with corporate identity requirements. These branding services support channel partners in building their market presence while offering proven tape technology to their customers.

Technical support services assist customers in optimizing tape selection and application methods for their specific automotive applications. Application engineering support helps identify the most suitable tape configuration for unique harness designs or environmental requirements. This technical collaboration ensures that customers achieve optimal results while minimizing application costs and maximizing reliability.

Packaging & Logistics Support

Professional packaging systems protect tape quality during storage, transportation, and handling throughout the distribution chain. Individual rolls are carefully wound and packaged to prevent damage while maintaining adhesive performance and substrate integrity. Protective packaging materials shield the tape from environmental factors that could affect its performance characteristics before application.

Efficient logistics support ensures reliable product availability for automotive manufacturing schedules and distribution requirements. Flexible packaging configurations accommodate various order quantities while optimizing shipping efficiency and storage convenience. Standardized packaging dimensions integrate seamlessly with automated material handling systems used in automotive production environments.

International shipping capabilities support global automotive manufacturers and distributors with reliable delivery services across multiple markets. Export packaging meets international shipping requirements while protecting product quality during extended transit times. Documentation services provide the necessary certification and compliance paperwork required for international automotive applications.

Why Choose Us

With extensive experience serving the global automotive industry, our company has established a reputation for delivering reliable electrical insulation solutions that meet the demanding requirements of modern vehicle manufacturing. Our international market presence and multi-industry expertise enable us to understand the unique challenges faced by automotive harness manufacturers and provide tailored solutions that address specific application requirements.

Our comprehensive approach to tape manufacturing encompasses everything from raw material selection to final quality verification, ensuring that every roll of Electrical Insulation Tape Heat-resistant Adhesive Masking Tape 19mm for Car Cable Harness Wiring meets the highest performance standards. Continuous investment in manufacturing technology and quality systems maintains our position as a trusted supplier to automotive OEMs and tier-one suppliers worldwide.

Technical innovation drives our product development efforts, resulting in advanced tape formulations that address evolving automotive industry requirements. Our research and development capabilities enable us to anticipate market needs and develop solutions that provide competitive advantages for our customers. This forward-thinking approach ensures that our products continue to meet the performance demands of next-generation automotive electrical systems.

Global collaboration with automotive manufacturers and harness suppliers provides valuable insights into emerging application requirements and performance challenges. This market intelligence informs our product development priorities and helps us deliver solutions that address real-world automotive applications. Our commitment to customer success extends beyond product delivery to include technical support and application engineering assistance.

Conclusion

The Electrical Insulation Tape Heat-resistant Adhesive Masking Tape 19mm for Car Cable Harness Wiring represents a significant advancement in automotive electrical insulation technology, delivering the superior performance characteristics required for modern vehicle applications. Its combination of exceptional heat resistance, reliable adhesion, and electrical insulation properties makes it an ideal choice for demanding automotive harness applications where traditional tapes often fail. The tape's proven durability and consistent performance ensure long-term reliability in the challenging environments encountered throughout automotive electrical systems. Professional manufacturers and distributors can confidently specify this advanced insulation solution knowing that it will deliver the protection and performance required for today's sophisticated automotive applications while supporting their quality and reliability objectives.

| item | value |

| Adhesive | Acrylic |

| Use | MASKING |

| Place of Origin | China |

| Adhesive Side | Single Sided |

| Material | Flannel |

| Type | Insulation Tape |

| Thickness | 0.3mm |

| Adhesive Type | Pressure Sensitive |

| Feature | Heat-resistant |

| Brand Name | YLW |

| Model Number | YLW-R001 |

| Design Printing | Offer Printing |

| cycle length | 10m |

| paper core | Customizable |

| Printing Handling | Offer printing |

| glue | Acrylic |

well

1. who are we?

We are based in Jiangsu, China, start from 2025,sell to Mid East(30.00%),Southeast Asia(20.00%),Central America(20.00%),North America(15.00%),South Asia(15.00%). There are total about - people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

automotive tape

4. why should you buy from us not from other suppliers?

-

5. what services can we provide?

Accepted Delivery Terms: -;

Accepted Payment Currency: -;

Accepted Payment Type: -;

Language Spoken: English