Introduction

In today's demanding automotive and industrial environments, reliable wire protection solutions have become essential for maintaining operational integrity and safety standards. The Fabric Wrap Harness Waterproof Heat-resistant Single Sided Acrylic Adhesive Auto Wiring Masking Cloth harness tape represents a breakthrough in protective wrapping technology, specifically engineered to address the complex challenges faced by modern electrical systems. This innovative textile-based solution combines advanced materials science with practical application requirements, delivering superior protection against environmental hazards while maintaining flexibility and ease of installation.

As electrical systems become increasingly sophisticated and operate under more extreme conditions, the need for dependable harness protection has intensified across multiple industries. This specialized fabric wrapping solution addresses critical pain points including moisture intrusion, thermal degradation, and mechanical wear, while providing the versatility required for diverse application scenarios. The single-sided acrylic adhesive system ensures secure bonding without compromising the underlying components, making it an ideal choice for both original equipment manufacturers and aftermarket applications.

Product Overview

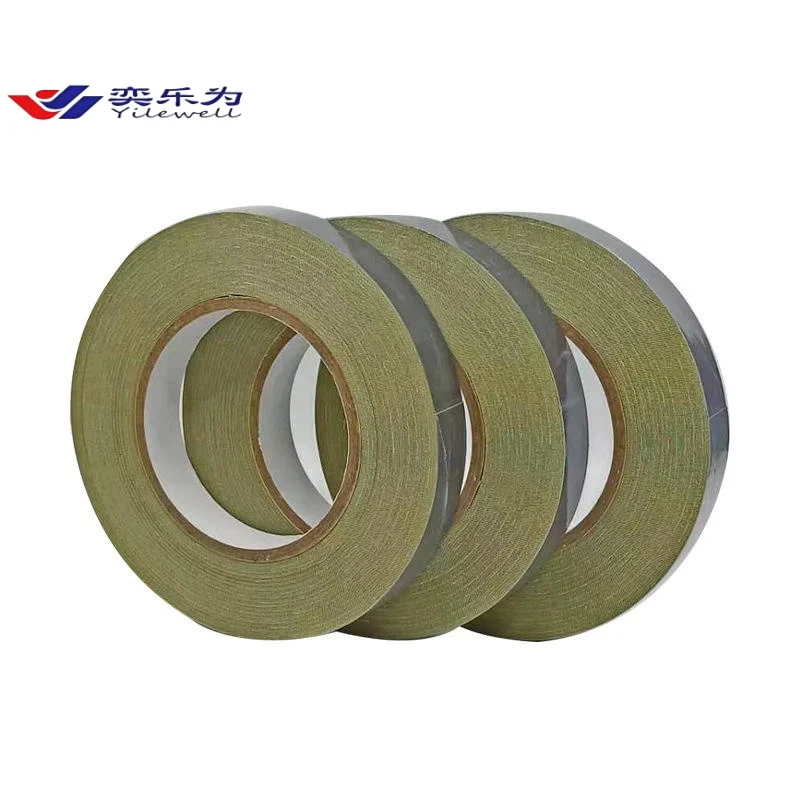

The Fabric Wrap Harness Waterproof Heat-resistant Single Sided Acrylic Adhesive Auto Wiring Masking Cloth harness tape stands as a premium protective solution meticulously designed for electrical harness applications. This high-performance tape combines a durable fabric substrate with advanced waterproof properties and exceptional heat resistance capabilities, creating a comprehensive protection system that excels in challenging operational environments. The single-sided acrylic adhesive formulation provides strong, permanent bonding while allowing for clean removal when necessary during maintenance procedures.

Built upon years of materials engineering expertise, this harness tape incorporates a carefully balanced composition that prioritizes both performance and practicality. The fabric construction offers superior conformability around irregular shapes and tight bends, while the waterproof barrier prevents moisture penetration that could compromise electrical integrity. The heat-resistant properties ensure reliable performance across wide temperature ranges, making it suitable for applications ranging from engine compartments to industrial machinery installations.

Features & Benefits

Advanced Material Properties

The sophisticated fabric construction of this harness tape delivers exceptional durability and flexibility, enabling it to withstand the mechanical stresses encountered in dynamic applications. The carefully selected textile fibers provide excellent abrasion resistance while maintaining the pliability necessary for wrapping around complex harness configurations. This balance of strength and flexibility ensures long-term protection without compromising the tape's ability to conform to irregular surfaces or accommodate cable movement during operation.

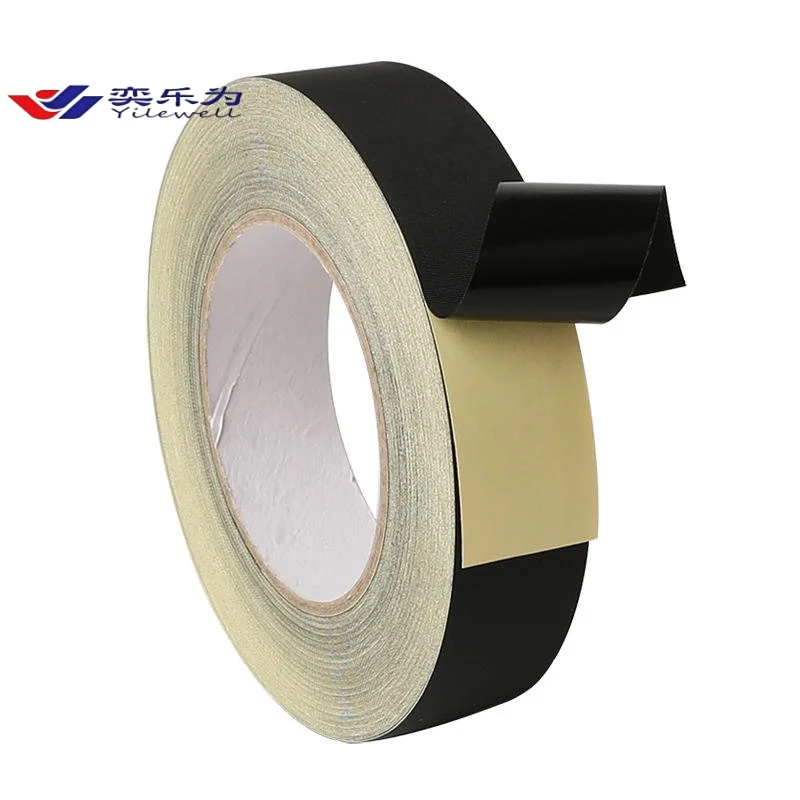

The waterproof characteristics represent a significant advancement in harness protection technology, utilizing specialized barrier materials that prevent moisture infiltration while allowing the tape to maintain its structural integrity over extended periods. This moisture protection extends beyond simple water resistance to include protection against humidity, condensation, and various automotive fluids that could otherwise compromise electrical connections and insulation systems.

Thermal Performance Excellence

Heat resistance capabilities distinguish this harness tape from conventional alternatives, enabling reliable performance in high-temperature environments where standard tapes would fail or degrade. The thermal stability ensures that adhesive properties remain consistent across wide temperature ranges, preventing bond failure during thermal cycling conditions commonly encountered in automotive and industrial applications. This thermal resilience extends the service life of wrapped harnesses while maintaining protection effectiveness throughout the operational temperature spectrum.

The single-sided acrylic adhesive system represents a carefully engineered solution that provides strong initial adhesion while allowing for repositioning during installation. This adhesive formulation resists temperature-induced changes in bonding characteristics, ensuring that the tape maintains its protective seal regardless of environmental temperature fluctuations. The acrylic base also contributes to the tape's resistance to aging and UV degradation, further enhancing its long-term reliability.

Applications & Use Cases

Automotive applications represent the primary market for this specialized Fabric Wrap Harness Waterproof Heat-resistant Single Sided Acrylic Adhesive Auto Wiring Masking Cloth harness tape, where it serves critical roles in protecting electrical systems from the harsh conditions encountered in vehicle operation. Engine compartment harnesses benefit significantly from the tape's heat resistance and waterproof properties, while interior applications utilize its clean appearance and reliable adhesion characteristics. The tape's conformability makes it particularly suitable for protecting harnesses that must navigate tight spaces or follow complex routing paths throughout the vehicle architecture.

Industrial machinery applications leverage the tape's robust construction and environmental resistance capabilities to protect control wiring and sensor cables in manufacturing environments. The textile-based design provides excellent protection against mechanical damage while maintaining the flexibility required for equipment that experiences regular movement or vibration. This versatility extends to marine applications, where the waterproof properties and corrosion resistance become critical factors in maintaining electrical system reliability in saltwater environments.

Aerospace and defense applications benefit from the tape's reliable performance characteristics and consistent quality standards, utilizing it for protecting sensitive electronic systems in demanding operational environments. The heat resistance properties prove particularly valuable in applications where harnesses must operate near high-temperature components or in environments with extreme temperature variations. Additionally, the tape's clean removal characteristics facilitate maintenance procedures without leaving residue that could interfere with system performance.

Quality Control & Compliance

Rigorous quality control processes ensure that every roll of this harness tape meets the exacting standards required for critical electrical protection applications. Comprehensive testing protocols evaluate adhesive performance, thermal stability, moisture resistance, and mechanical properties throughout the manufacturing process. These quality measures extend from raw material selection through final product inspection, guaranteeing consistent performance characteristics that professionals can depend upon for their most demanding applications.

Compliance with international standards demonstrates the tape's suitability for global markets and diverse application requirements. The manufacturing processes incorporate environmental considerations while maintaining the performance standards necessary for professional-grade applications. Quality documentation supports traceability requirements and provides the technical validation needed for integration into certified systems and processes.

Ongoing quality assurance programs monitor product performance through field testing and customer feedback, enabling continuous improvement initiatives that enhance product capabilities while maintaining compatibility with existing application methods. This commitment to quality excellence ensures that the Fabric Wrap Harness Waterproof Heat-resistant Single Sided Acrylic Adhesive Auto Wiring Masking Cloth harness tape continues to meet evolving industry requirements.

Customization & Branding Options

Recognizing the diverse requirements of global markets, comprehensive customization capabilities enable tailoring of this harness tape to meet specific application needs and branding requirements. Color options extend beyond standard black to include various automotive and industrial color codes, facilitating integration with existing wire marking and identification systems. Width variations accommodate different harness sizes and wrapping techniques, while adhesive formulation adjustments can address specific environmental or performance requirements.

Private labeling services support brand building initiatives for distributors and equipment manufacturers, providing professional packaging and documentation that reinforces brand identity while maintaining product quality standards. Custom printing capabilities enable the incorporation of part numbers, specifications, or safety information directly onto the tape surface, enhancing traceability and reducing installation errors in complex systems.

Technical customization extends to specialized formulations designed for unique environmental conditions or industry-specific requirements. Whether addressing extreme temperature ranges, specific chemical exposures, or unique adhesion challenges, engineering support services work closely with customers to develop optimal solutions that maintain the core benefits of the standard product while addressing specialized needs.

Packaging & Logistics Support

Professional packaging solutions protect product integrity throughout the distribution chain while supporting efficient handling and storage at customer facilities. Moisture-resistant packaging maintains adhesive performance during extended storage periods, while clearly marked cartons facilitate accurate inventory management. Roll packaging designs accommodate both manual and automated dispensing systems, supporting diverse installation methods and workflow requirements.

Global logistics capabilities ensure reliable product availability across international markets, with regional distribution centers providing responsive service to local customers. Flexible packaging configurations accommodate varying order quantities while maintaining cost-effectiveness for both large-scale production runs and specialized applications. Documentation packages include technical specifications, application guidelines, and safety information in multiple languages to support international distribution requirements.

Inventory management support services help customers optimize stock levels while ensuring product availability for critical applications. Just-in-time delivery capabilities reduce customer inventory carrying costs while maintaining production continuity. Special handling procedures protect product quality during transportation, ensuring that performance characteristics remain consistent from manufacturing through end-use application.

Why Choose Us

Our company brings decades of experience in advanced adhesive technologies and textile engineering to the development and manufacturing of professional-grade harness protection solutions. This extensive background in materials science, combined with deep understanding of automotive and industrial application requirements, positions us as a trusted partner for customers seeking reliable protection solutions. Our global presence spans multiple continents, enabling us to serve diverse markets while maintaining consistent quality standards and responsive customer support.

As a recognized metal packaging supplier and custom tin box supplier, our expertise extends across multiple industries, providing valuable cross-pollination of technologies and application insights. This diverse experience enhances our ability to develop innovative solutions that address emerging market needs while maintaining the reliability required for critical applications. Our OEM tin packaging solutions experience demonstrates our commitment to customer-specific requirements and quality excellence.

Continuous investment in research and development ensures that our products remain at the forefront of industry innovation, incorporating the latest advances in materials science and manufacturing technology. Our engineering team collaborates closely with customers to understand evolving requirements and develop solutions that anticipate future needs. This forward-thinking approach, combined with proven manufacturing capabilities, makes us the preferred partner for companies seeking reliable, high-performance harness protection solutions.

Conclusion

The Fabric Wrap Harness Waterproof Heat-resistant Single Sided Acrylic Adhesive Auto Wiring Masking Cloth harness tape represents a significant advancement in electrical system protection technology, combining superior materials engineering with practical application benefits. Its comprehensive protection capabilities, including waterproof barriers, heat resistance, and durable fabric construction, make it an essential component for maintaining electrical system integrity in demanding environments. The versatile design accommodates diverse application requirements while providing the reliability necessary for critical systems protection. Through continuous innovation and commitment to quality excellence, this harness tape solution delivers the performance characteristics that modern electrical systems require, establishing it as the preferred choice for professionals who demand superior protection capabilities and dependable results.

| item | value |

| Adhesive | Acrylic |

| Use | MASKING |

| Place of Origin | China |

| Adhesive Side | Single Sided |

| Material | Cloth |

| Type | Adhesive Sticker |

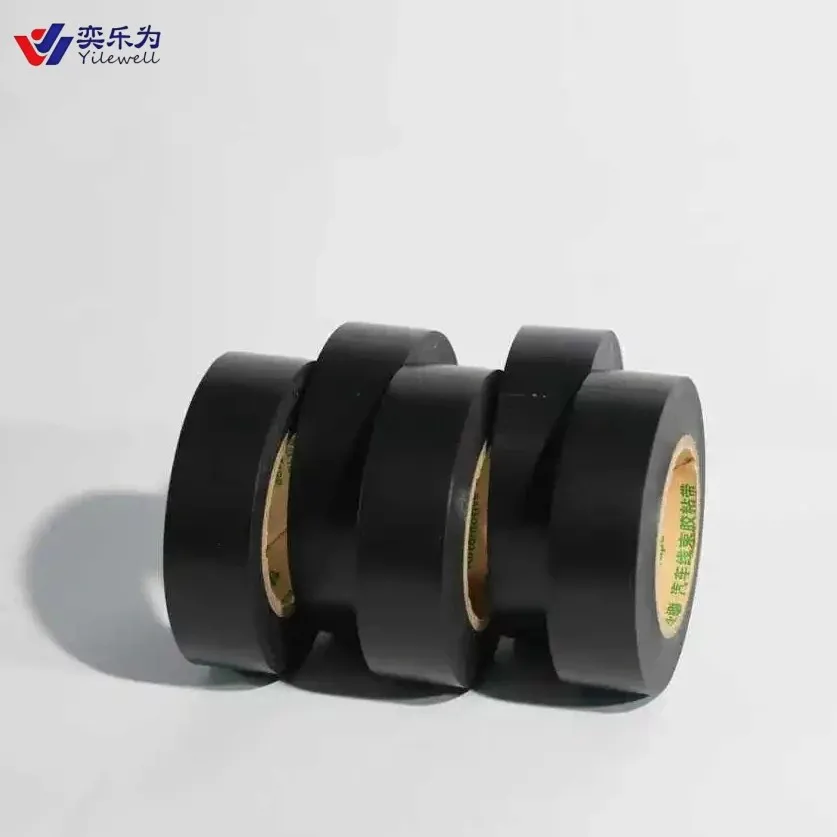

| Thickness | 0.26mm |

| Adhesive Type | Pressure Sensitive |

| Feature | Heat-resistant |

| Brand Name | YLW |

| Model Number | YLW-- B005 |

| Design Printing | No printing |

| cycle length | 25m |

| paper core | No paper core. |

| Printing Handling | No printing |

| glue | Acrylic |

well

1. who are we?

We are based in Jiangsu, China, start from 2025,sell to Mid East(30.00%),Southeast Asia(20.00%),Central America(20.00%),North America(15.00%),South Asia(15.00%). There are total about - people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

automotive tape

4. why should you buy from us not from other suppliers?

-

5. what services can we provide?

Accepted Delivery Terms: -;

Accepted Payment Currency: -;

Accepted Payment Type: -;

Language Spoken: English