Introduction

In the demanding world of automotive manufacturing and maintenance, professionals require specialized adhesive solutions that can withstand extreme conditions while maintaining superior performance. The Heat-resistant Flame Retardant Flannel Pressure Sensitive Masking Tape Insulated Automotive Car Use Black represents a breakthrough in protective masking technology, specifically engineered for high-temperature automotive applications. This advanced masking solution combines the durability of flame-retardant materials with the precision required for professional automotive finishing processes.

Modern automotive environments present unique challenges that standard masking tapes simply cannot address. From engine compartments reaching elevated temperatures to paint booths requiring heat-resistant protection, automotive professionals need reliable masking solutions that maintain their integrity under stress. This specialized flannel-based masking tape delivers exceptional performance in the most demanding automotive applications, ensuring clean lines, reliable adhesion, and safe operation in temperature-sensitive environments.

Product Overview

The Heat-resistant Flame Retardant Flannel Pressure Sensitive Masking Tape Insulated Automotive Car Use Black is specifically designed to meet the rigorous demands of automotive applications. This professional-grade masking tape features a unique flannel backing that provides exceptional conformability and heat resistance, making it ideal for use in high-temperature automotive environments. The black coloration offers superior visibility during application and removal processes, ensuring precise masking boundaries in various lighting conditions.

This innovative masking solution incorporates advanced flame-retardant properties that enhance safety in automotive workshops and manufacturing facilities. The pressure-sensitive adhesive system ensures reliable bonding to various automotive surfaces while maintaining clean removal characteristics when the masking process is complete. The flannel construction provides excellent flexibility, allowing the tape to conform to curved surfaces and complex geometries commonly found in automotive applications.

Engineered for professional use, this masking tape combines thermal stability with mechanical durability to deliver consistent performance across a wide range of automotive applications. The specialized formulation resists degradation under elevated temperatures while maintaining its adhesive properties and structural integrity throughout the masking process.

Features & Benefits

Advanced Heat Resistance Technology

The exceptional heat resistance of this flannel masking tape sets it apart from conventional masking solutions. The specialized construction maintains dimensional stability and adhesive performance even when exposed to elevated temperatures commonly encountered in automotive environments. This thermal stability ensures that masking boundaries remain sharp and precise throughout heat-intensive processes such as paint curing and component assembly.

The flame-retardant properties provide an additional layer of safety in automotive applications where heat sources and potential ignition risks are present. This safety feature reduces fire hazards in workshop environments while maintaining the tape's primary masking functionality. The heat-resistant characteristics also prevent adhesive migration and backing degradation, ensuring clean removal without residue or surface damage.

Superior Flannel Construction

The flannel backing material offers unique advantages in automotive masking applications. This textile-based construction provides exceptional conformability, allowing the tape to follow complex contours and irregular surfaces commonly found in automotive components. The flannel structure also offers enhanced tear resistance, reducing waste and improving application efficiency during masking operations.

The black coloration of the flannel backing provides excellent contrast against most automotive surfaces, improving visibility during application and ensuring precise masking boundaries. This visual advantage is particularly valuable in low-light workshop conditions or when working with dark-colored automotive components where masking boundaries might otherwise be difficult to distinguish.

Professional-Grade Adhesive System

The pressure-sensitive adhesive system delivers reliable bonding performance across a wide range of automotive surfaces, including painted finishes, metal components, and plastic trim pieces. The adhesive formulation balances strong initial tack with clean removability, ensuring that masking boundaries remain secure during processing while allowing easy removal without surface damage or residue.

This advanced adhesive technology maintains its bonding characteristics even under thermal stress, preventing lifting or edge curling that could compromise masking integrity. The pressure-sensitive nature of the adhesive allows for easy repositioning during initial application while developing full bond strength once properly positioned.

Applications & Use Cases

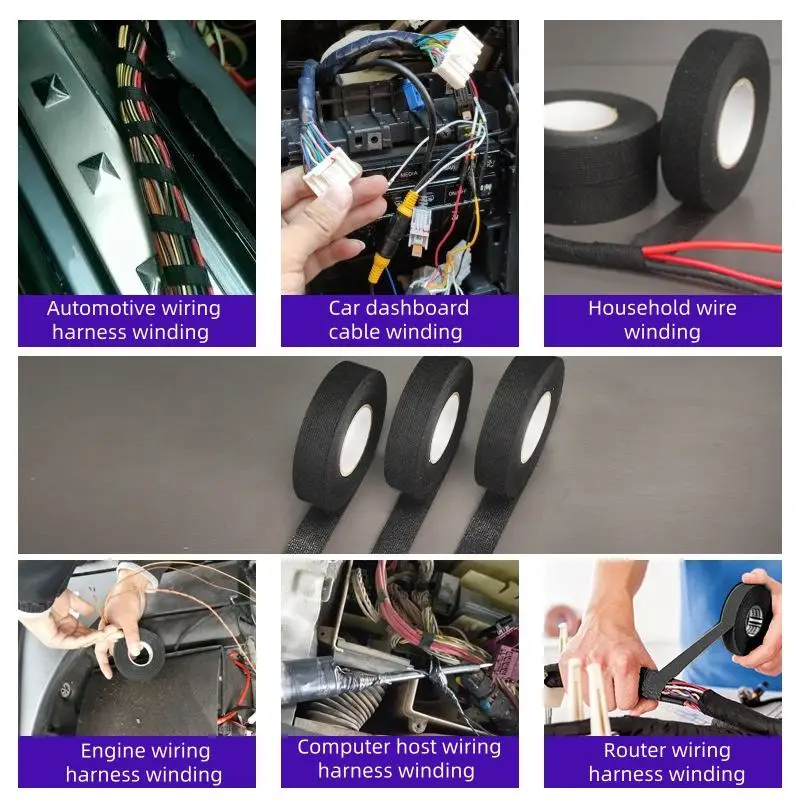

The Heat-resistant Flame Retardant Flannel Pressure Sensitive Masking Tape Insulated Automotive Car Use Black excels in numerous automotive applications where standard masking tapes fall short. Paint booth operations benefit significantly from this tape's heat resistance, as it maintains its integrity during elevated-temperature curing processes while providing sharp, clean masking lines. The flame-retardant properties add an essential safety element in paint booths where solvent vapors and heat sources create potential fire risks.

Engine compartment masking represents another critical application area where this specialized tape demonstrates its value. The combination of heat resistance and conformability allows technicians to mask complex engine geometries while protecting sensitive components during maintenance or restoration procedures. The black coloration provides excellent visibility against typical engine compartment surfaces, ensuring precise masking boundaries even in challenging lighting conditions.

Automotive restoration projects particularly benefit from this tape's unique properties. Classic car restoration often involves extended exposure to heat during paint stripping, bodywork, and refinishing processes. The thermal stability of this masking tape ensures that protective boundaries remain intact throughout these lengthy procedures, while the flannel construction conforms to the complex curves and details characteristic of vintage automotive designs.

Body shop applications represent a primary market for this specialized masking solution. Professional auto body technicians require masking tapes that can withstand the heat generated by infrared curing lamps and spray booth operations while maintaining precise masking boundaries. The Heat-resistant Flame Retardant Flannel Pressure Sensitive Masking Tape Insulated Automotive Car Use Black meets these demanding requirements while providing the reliability and consistency that professional body shops demand.

Quality Control & Compliance

Manufacturing excellence drives every aspect of production for this specialized automotive masking tape. Rigorous quality control processes ensure consistent performance characteristics across every roll, with particular attention paid to heat resistance properties and flame-retardant effectiveness. Advanced testing protocols validate thermal stability, adhesive performance, and flame-retardant characteristics to ensure that every product meets the demanding requirements of automotive applications.

Environmental compliance represents a key consideration in the manufacturing process, with production methods designed to minimize environmental impact while maintaining superior product performance. The manufacturing facilities operate under strict quality management systems that ensure consistent product quality and regulatory compliance across international markets.

Raw material selection follows stringent standards to ensure that all components meet the performance requirements necessary for automotive applications. The flannel backing material undergoes comprehensive testing for heat resistance and flame-retardant properties, while the adhesive system is validated for thermal stability and clean removal characteristics. These quality measures ensure that every roll of tape delivers the reliability and performance that automotive professionals demand.

Batch testing and documentation provide traceability and quality assurance throughout the production process. Each production run undergoes comprehensive testing to verify that heat resistance, flame-retardant properties, and adhesive performance meet established specifications. This systematic approach to quality control ensures consistent product performance and builds confidence among automotive professionals who rely on this specialized masking solution.

Customization & Branding Options

Understanding that different automotive applications may require specific performance characteristics or dimensions, comprehensive customization options are available for the Heat-resistant Flame Retardant Flannel Pressure Sensitive Masking Tape Insulated Automotive Car Use Black. Width variations can be tailored to meet specific masking requirements, while adhesive formulations can be adjusted to optimize performance for particular surface types or temperature ranges commonly encountered in specialized automotive applications.

Private labeling and custom packaging solutions enable distributors and automotive suppliers to develop their own branded masking tape products while leveraging proven manufacturing expertise. Custom packaging options include specialized dispensing systems, protective wrapping materials, and identification labels that facilitate inventory management and product identification in busy automotive workshops.

Roll length customization accommodates different usage patterns and inventory management preferences, allowing automotive suppliers to optimize their product offerings for specific market segments. Whether serving large-scale automotive manufacturing operations or specialized restoration shops, customized roll configurations ensure efficient product utilization and reduced waste.

Technical specification modifications can address unique application requirements that may arise in specialized automotive markets. Adhesive strength adjustments, backing material variations, and flame-retardant property enhancements can be implemented to meet specific performance criteria or regulatory requirements in different international markets.

Packaging & Logistics Support

Professional packaging solutions protect the Heat-resistant Flame Retardant Flannel Pressure Sensitive Masking Tape Insulated Automotive Car Use Black during storage and transportation while maintaining product quality and performance characteristics. Moisture-resistant packaging materials prevent environmental degradation of the flannel backing and adhesive system, ensuring that the tape maintains its specified performance characteristics from manufacturing through end-use application.

Efficient logistics support facilitates global distribution of this specialized masking tape to automotive markets worldwide. Optimized packaging configurations maximize shipping efficiency while minimizing transportation costs, enabling competitive pricing for international customers. Temperature-controlled storage recommendations ensure that the tape's heat-resistant and flame-retardant properties remain stable during extended storage periods.

Inventory management support includes clear product identification systems and storage recommendations that help distributors and end-users maintain optimal product conditions. Proper inventory rotation procedures and environmental storage requirements are documented to ensure that the tape maintains its performance characteristics throughout its shelf life.

International shipping compliance addresses regulatory requirements and documentation needs for global distribution. Proper classification and documentation ensure smooth customs clearance and regulatory compliance in diverse international markets, facilitating efficient global distribution of this specialized automotive masking solution.

Why Choose Us

With extensive experience serving automotive markets across multiple continents, our company has established itself as a trusted partner for specialized adhesive solutions in demanding industrial applications. Our deep understanding of automotive manufacturing processes and maintenance requirements drives continuous innovation in masking tape technology, ensuring that our products meet the evolving needs of modern automotive professionals.

Our commitment to quality extends beyond product manufacturing to encompass comprehensive customer support and technical assistance. International automotive distributors and suppliers benefit from our global market presence and multi-industry expertise, which enables us to provide insights and solutions that address specific regional requirements and application challenges. This collaborative approach has established long-term partnerships with leading automotive suppliers and custom packaging manufacturers worldwide.

Advanced manufacturing capabilities and quality control systems ensure consistent product performance across all production runs. Our facilities operate under internationally recognized quality management standards, providing the reliability and consistency that automotive professionals require. Whether serving as a specialized automotive tape supplier or supporting custom packaging solutions for automotive markets, our manufacturing expertise delivers products that meet the most demanding performance requirements.

Research and development investments drive continuous improvement in heat-resistant masking tape technology. Our technical team works closely with automotive professionals to understand emerging application requirements and develop innovative solutions that address new challenges in automotive manufacturing and maintenance. This commitment to innovation ensures that our Heat-resistant Flame Retardant Flannel Pressure Sensitive Masking Tape Insulated Automotive Car Use Black remains at the forefront of automotive masking tape technology.

Conclusion

The Heat-resistant Flame Retardant Flannel Pressure Sensitive Masking Tape Insulated Automotive Car Use Black represents a significant advancement in automotive masking tape technology, combining exceptional heat resistance with flame-retardant safety features and superior flannel construction. This specialized masking solution addresses the unique challenges faced by automotive professionals, from paint booth operations to engine compartment maintenance, while delivering the reliability and performance consistency that modern automotive applications demand. The combination of advanced materials technology, rigorous quality control, and comprehensive customization options makes this masking tape an essential tool for automotive professionals who require superior performance in demanding thermal environments. Through its innovative design and proven performance characteristics, this specialized masking tape continues to set new standards for automotive adhesive solutions in the global marketplace.

| item | value |

| Adhesive | Acrylic |

| Use | MASKING |

| Place of Origin | China |

| Adhesive Side | Single Sided |

| Material | Flannel |

| Type | Insulation Tape |

| Thickness | 0.3mm |

| Adhesive Type | Pressure Sensitive |

| Feature | Heat-resistant |

| Brand Name | YLW |

| Model Number | YLW-R001 |

| Design Printing | Offer Printing |

| cycle length | 10m |

| paper core | Customizable |

| Printing Handling | Offer printing |

| glue | Acrylic |

well

1. who are we?

We are based in Jiangsu, China, start from 2025,sell to Mid East(30.00%),Southeast Asia(20.00%),Central America(20.00%),North America(15.00%),South Asia(15.00%). There are total about - people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

automotive tape

4. why should you buy from us not from other suppliers?

-

5. what services can we provide?

Accepted Delivery Terms: -;

Accepted Payment Currency: -;

Accepted Payment Type: -;

Language Spoken: English