Introduction

Modern industrial environments demand specialized materials that can withstand extreme conditions while providing reliable performance across multiple applications. The Industrial Flannel Insulation Tape-Pressure Sensitive Adhesive Fire Resistant Heat Resistant for Masking Noise Suppression Shock represents a breakthrough solution engineered for demanding industrial sectors requiring superior thermal protection, acoustic dampening, and vibration control. This advanced insulation tape combines the natural properties of flannel with cutting-edge adhesive technology, delivering exceptional fire resistance and heat tolerance that exceeds conventional protective materials.

Designed for professional applications where safety and reliability cannot be compromised, this industrial-grade tape serves as a critical component in manufacturing processes, automotive assembly, aerospace applications, and heavy machinery operations. The unique construction methodology ensures consistent performance under variable environmental conditions, making it an indispensable resource for engineers and procurement specialists seeking comprehensive protection solutions.

Product Overview

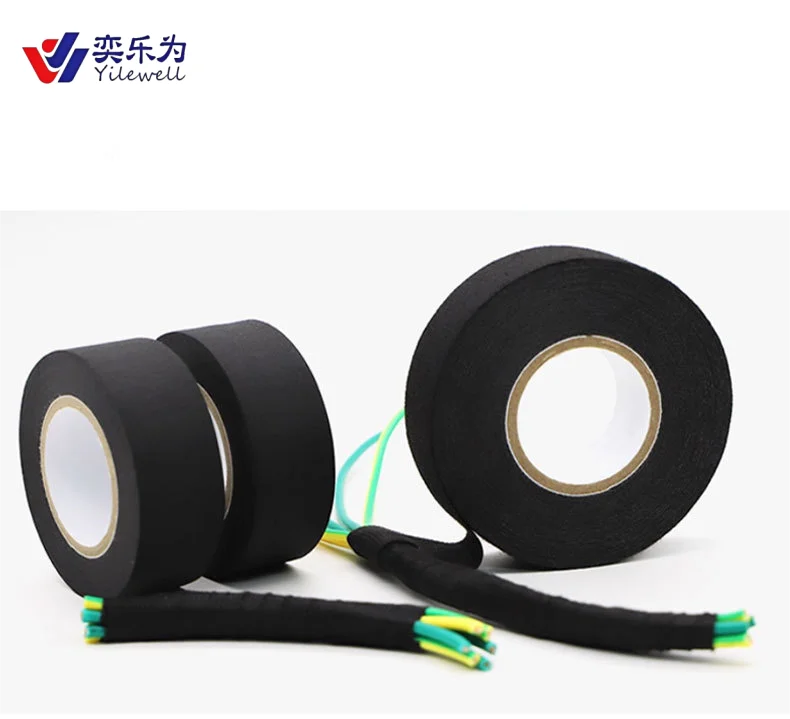

The Industrial Flannel Insulation Tape-Pressure Sensitive Adhesive Fire Resistant Heat Resistant for Masking Noise Suppression Shock incorporates advanced material science to address multiple industrial challenges simultaneously. The flannel substrate provides excellent conformability and cushioning properties, while the specialized pressure-sensitive adhesive maintains secure bonding even under thermal stress and mechanical vibration. This dual-functionality design eliminates the need for multiple separate products, streamlining inventory management and installation processes.

Manufacturing excellence ensures consistent thickness, adhesion strength, and thermal performance across every roll. The tape's construction utilizes premium-grade flannel fibers that resist degradation under prolonged exposure to elevated temperatures and harsh chemical environments. The pressure-sensitive adhesive formulation maintains its bonding characteristics across a wide temperature range, ensuring reliable performance in both high-heat applications and ambient temperature installations.

Quality control protocols verify that each production batch meets stringent performance standards for fire resistance, heat tolerance, and adhesive strength. The manufacturing process incorporates multiple inspection points to guarantee uniformity and eliminate defects that could compromise field performance. This attention to detail ensures that every installation delivers the expected protection and longevity.

Features & Benefits

Superior Fire Resistance and Heat Protection

The fire-resistant properties of this Industrial Flannel Insulation Tape-Pressure Sensitive Adhesive Fire Resistant Heat Resistant for Masking Noise Suppression Shock provide critical safety advantages in high-risk environments. The specialized flannel construction inhibits flame propagation while maintaining structural integrity under extreme heat exposure. This characteristic makes it essential for applications near furnaces, welding operations, and engine compartments where fire protection is paramount.

Heat resistance capabilities extend beyond basic fire protection to include sustained thermal exposure resistance. The tape maintains its protective properties and adhesive strength even when subjected to continuous elevated temperatures, ensuring long-term reliability in demanding industrial settings. This thermal stability reduces maintenance requirements and replacement frequency, contributing to overall operational efficiency.

Advanced Acoustic and Vibration Control

Noise suppression functionality addresses critical workplace safety and comfort requirements while protecting sensitive equipment from acoustic damage. The flannel substrate effectively absorbs and dampens sound waves across multiple frequency ranges, reducing ambient noise levels in industrial environments. This acoustic performance contributes to improved working conditions and compliance with occupational health standards.

Shock and vibration dampening properties protect delicate components and reduce wear on mechanical systems. The tape's cushioning characteristics absorb impact forces and minimize vibration transmission, extending equipment lifespan and reducing maintenance costs. This multi-functional protection capability makes it invaluable for applications involving rotating machinery, transportation equipment, and precision instruments.

Exceptional Adhesion and Conformability

The pressure-sensitive adhesive system provides immediate bonding without requiring heat activation or additional fasteners. This characteristic enables rapid installation and repositioning during assembly processes, improving productivity and reducing labor costs. The adhesive maintains its grip strength across various substrate materials, including metals, plastics, and composite surfaces.

Conformability to irregular surfaces ensures complete contact and uniform protection across complex geometries. The flannel substrate flexes and adapts to curves, corners, and textured surfaces while maintaining continuous coverage. This adaptability eliminates gaps and weak points that could compromise protective performance.

Applications & Use Cases

Industrial manufacturing facilities utilize this Industrial Flannel Insulation Tape-Pressure Sensitive Adhesive Fire Resistant Heat Resistant for Masking Noise Suppression Shock for thermal barrier applications around high-temperature processes. Steel mills, foundries, and glass manufacturing operations rely on its fire-resistant properties to protect adjacent equipment and structures from radiant heat damage. The tape's ability to maintain integrity under extreme conditions makes it suitable for furnace insulation, pipe wrapping, and heat shield applications.

Automotive and transportation industries implement this insulation solution for engine compartment protection, exhaust system shielding, and interior noise reduction. The combination of heat resistance and acoustic dampening addresses multiple vehicle design requirements simultaneously. Commercial vehicle manufacturers particularly value its durability under constant vibration and temperature cycling conditions typical in heavy-duty applications.

Aerospace applications demand materials that meet stringent safety and performance requirements while minimizing weight penalties. This insulation tape provides essential fire protection for aircraft systems while contributing to noise reduction in passenger and cargo areas. Its reliable performance under altitude and temperature variations makes it suitable for both commercial and military aircraft applications.

Power generation facilities use this protective tape for turbine insulation, electrical enclosure protection, and maintenance masking applications. The fire-resistant characteristics provide safety margins during routine maintenance procedures, while the heat resistance ensures continuous protection during normal operations. Nuclear, coal, and gas-fired power plants benefit from its reliable performance in challenging environments.

Quality Control & Compliance

Rigorous quality assurance processes ensure that every roll of Industrial Flannel Insulation Tape-Pressure Sensitive Adhesive Fire Resistant Heat Resistant for Masking Noise Suppression Shock meets or exceeds industry performance standards. Manufacturing facilities implement comprehensive testing protocols that verify fire resistance, heat tolerance, adhesion strength, and dimensional consistency. These quality measures guarantee reliable field performance across diverse applications and environmental conditions.

International compliance standards guide product development and manufacturing processes, ensuring compatibility with global safety regulations and industry requirements. Regular third-party testing validates performance claims and maintains certification currency across multiple international markets. This compliance framework provides confidence for engineers and procurement professionals specifying materials for critical applications.

Batch tracking systems maintain complete traceability from raw materials through finished product delivery. This documentation capability supports quality investigations and enables rapid response to any field performance concerns. The systematic approach to quality management ensures consistent product characteristics and facilitates continuous improvement initiatives.

Customization & Branding Options

Tailored solutions address specific industry requirements through customized adhesive formulations, substrate modifications, and dimensional specifications. Engineering teams collaborate with customers to develop optimized configurations that match unique application demands. This flexibility ensures optimal performance while maintaining cost-effectiveness for large-volume applications.

Private labeling capabilities enable distributors and OEM partners to market the Industrial Flannel Insulation Tape-Pressure Sensitive Adhesive Fire Resistant Heat Resistant for Masking Noise Suppression Shock under their own brand identity. Custom packaging options include specialized labeling, color coding, and documentation packages that align with customer requirements. This branding flexibility supports market differentiation and customer relationship development.

Technical support services assist with product selection, application guidance, and performance optimization. Experienced application engineers provide consultation on installation techniques, substrate preparation, and environmental considerations. This technical partnership approach ensures successful implementation and maximizes product performance in customer applications.

Packaging & Logistics Support

Protective packaging systems preserve product quality during transportation and storage while facilitating efficient handling at customer facilities. Moisture barrier protection prevents adhesive degradation, while impact-resistant containers protect against shipping damage. The packaging design optimizes space utilization for cost-effective transportation across international supply chains.

Global distribution capabilities ensure reliable product availability across major industrial markets. Strategic inventory positioning reduces lead times and supports just-in-time manufacturing requirements. The logistics network accommodates both small specialty orders and large-scale production requirements with equal attention to delivery performance.

Documentation packages include technical data sheets, safety information, and application guidelines in multiple languages. This comprehensive information support facilitates product specification, installation training, and regulatory compliance activities. Digital access to technical resources enables immediate information retrieval and supports remote consultation services.

Why Choose Us

Our organization brings decades of experience in advanced material development and manufacturing excellence to the industrial insulation market. International presence across major industrial regions ensures responsive service and technical support for global customers. This market position reflects our commitment to innovation and customer satisfaction in demanding industrial applications.

Collaboration with leading manufacturers and engineering firms drives continuous product improvement and application development. Our multi-industry expertise spans automotive, aerospace, power generation, and heavy manufacturing sectors, providing comprehensive understanding of diverse performance requirements. This broad experience base enables effective solution development for challenging applications.

Research and development investments focus on emerging technologies and evolving industry requirements. Advanced testing facilities validate product performance under realistic operating conditions, ensuring reliable field performance. This commitment to innovation maintains our position as a trusted supplier of high-performance industrial materials.

Customer partnerships extend beyond product supply to include technical consultation, application development, and ongoing support services. This comprehensive approach ensures successful implementation and maximizes the value of our Industrial Flannel Insulation Tape-Pressure Sensitive Adhesive Fire Resistant Heat Resistant for Masking Noise Suppression Shock in customer applications.

Conclusion

The Industrial Flannel Insulation Tape-Pressure Sensitive Adhesive Fire Resistant Heat Resistant for Masking Noise Suppression Shock represents a comprehensive solution for demanding industrial protection requirements. Its combination of fire resistance, heat tolerance, acoustic dampening, and vibration control capabilities addresses multiple application challenges with a single, reliable product. The advanced material construction and manufacturing excellence ensure consistent performance across diverse environmental conditions and industrial sectors. For procurement professionals and engineers seeking dependable protection solutions, this insulation tape delivers the performance, reliability, and versatility required for critical industrial applications.

| item | value |

| Adhesive | Acrylic |

| Use | MASKING |

| Place of Origin | China |

| Adhesive Side | Single Sided |

| Material | Flannel |

| Type | Insulation Tape |

| Thickness | 0.3mm |

| Adhesive Type | Pressure Sensitive |

| Feature | Heat-resistant |

| Brand Name | YLW |

| Model Number | YLW-R001 |

| Design Printing | Offer Printing |

| cycle length | 10m |

| paper core | Customizable |

| Printing Handling | Offer printing |

| glue | Acrylic |

well

1. who are we?

We are based in Jiangsu, China, start from 2025,sell to Mid East(30.00%),Southeast Asia(20.00%),Central America(20.00%),North America(15.00%),South Asia(15.00%). There are total about - people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

automotive tape

4. why should you buy from us not from other suppliers?

-

5. what services can we provide?

Accepted Delivery Terms: -;

Accepted Payment Currency: -;

Accepted Payment Type: -;

Language Spoken: English