Introduction

In today's demanding industrial landscape, reliable adhesive solutions are essential for electrical, automotive, and manufacturing applications. The PET Cloth Fabric Single Sided Pressure Sensitive Masking Tape Heat-Resistant Acrylic Adhesive Sticker No Residue 25m harness tape represents a sophisticated bonding solution designed to meet the rigorous requirements of professional wire harnessing, cable management, and high-temperature applications. This specialized tape combines the durability of polyethylene terephthalate cloth backing with advanced acrylic adhesive technology, delivering exceptional performance where traditional masking tapes fall short. Professional engineers and procurement specialists worldwide recognize the critical importance of selecting the right adhesive products for mission-critical applications, making this heat-resistant harness tape an indispensable component in modern manufacturing processes.

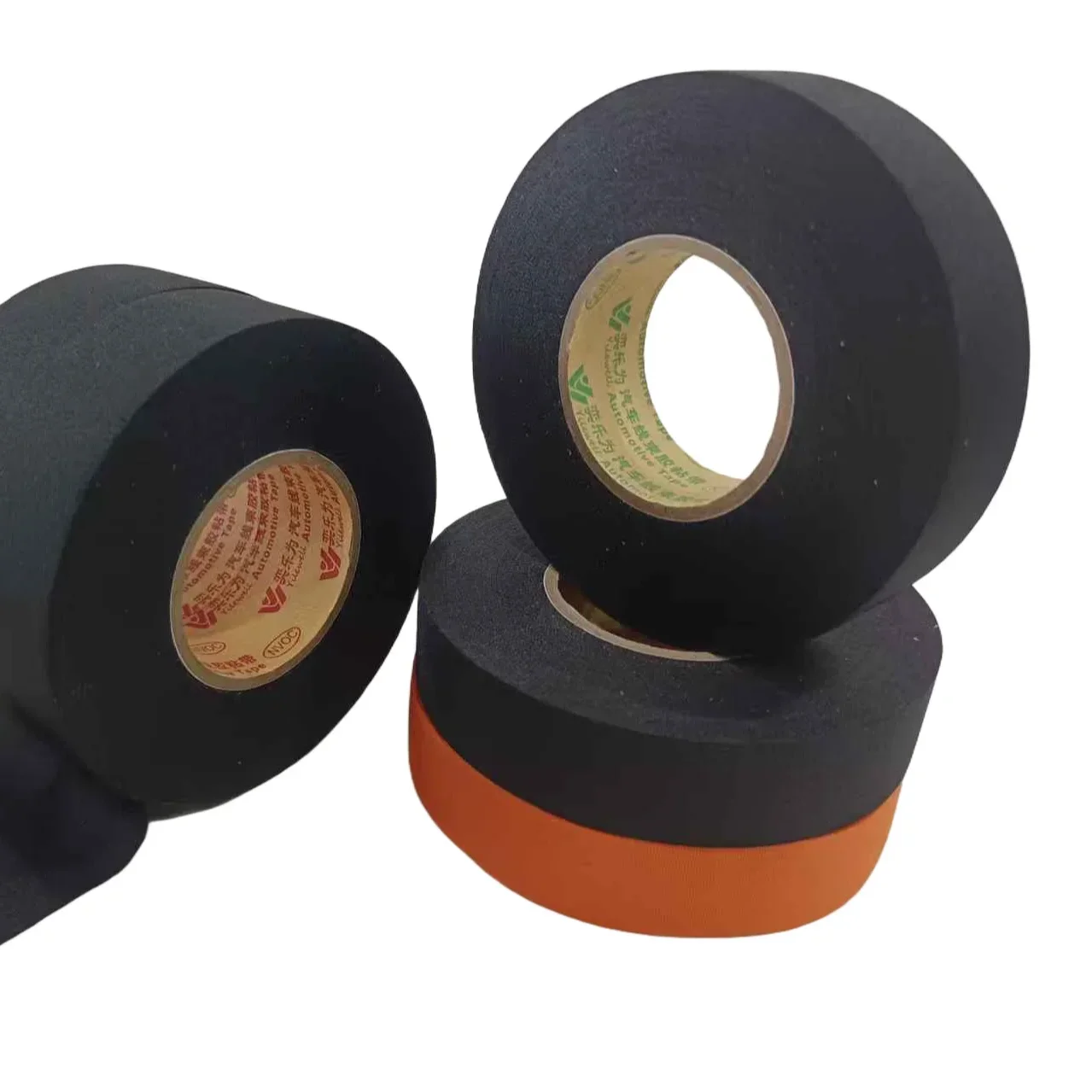

Product Overview

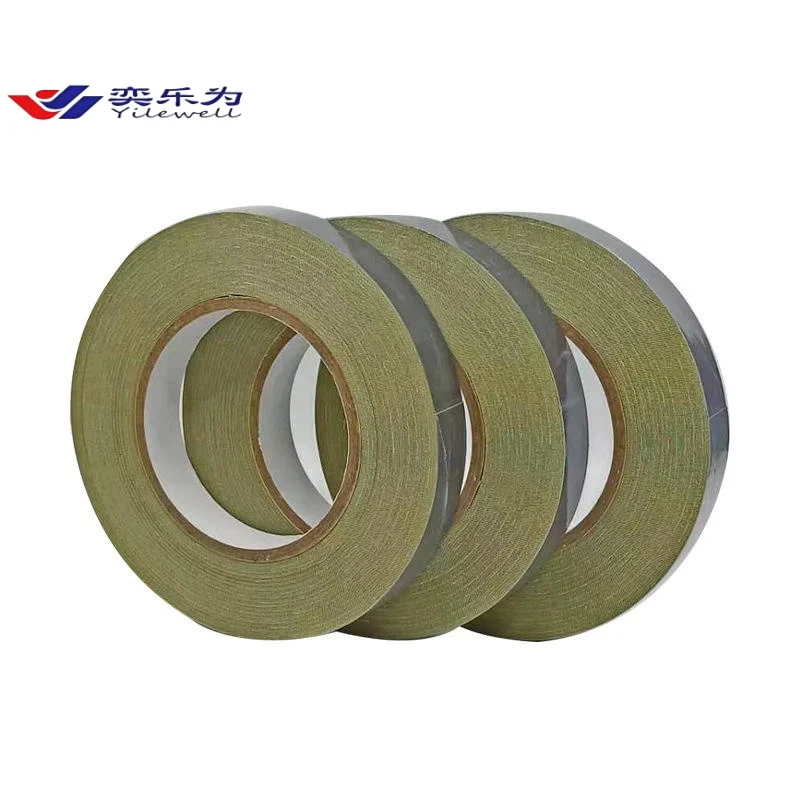

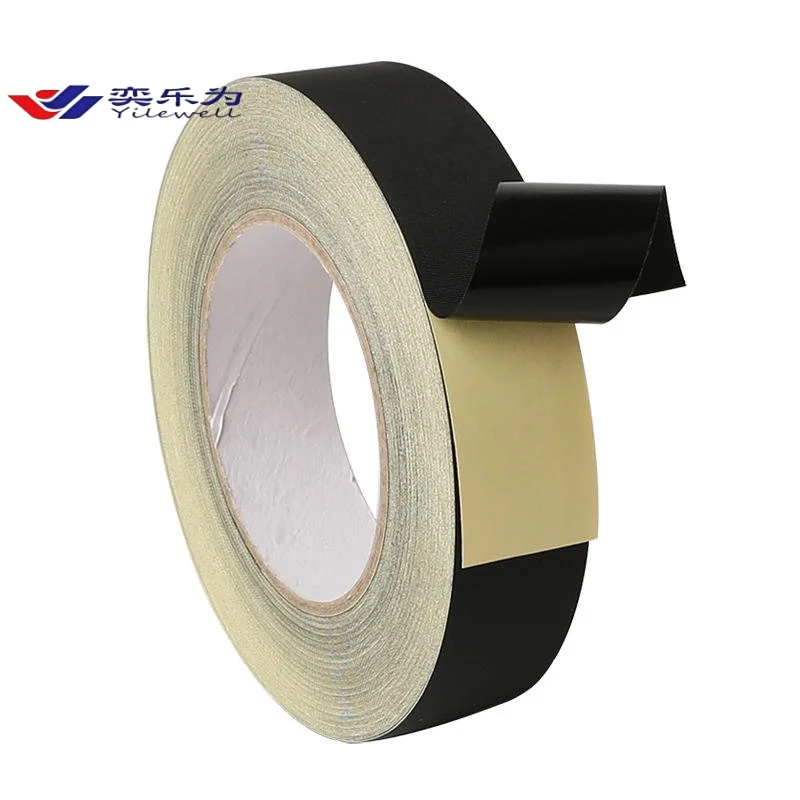

This premium harness tape features a robust PET cloth fabric construction that provides superior tensile strength and dimensional stability under challenging operating conditions. The single-sided pressure sensitive design incorporates a high-performance acrylic adhesive system engineered to maintain consistent bonding properties across a wide temperature range. The cloth fabric backing offers exceptional conformability, allowing the tape to adapt to irregular surfaces and complex geometric configurations commonly encountered in wire harness assemblies and cable bundling applications.

The innovative acrylic adhesive formulation ensures clean removal without leaving residual deposits on substrates, addressing a common concern in temporary masking and bundling operations. This no-residue characteristic makes the tape particularly valuable in applications where surface integrity must be preserved after tape removal. The extended length format provides excellent value for high-volume operations while reducing the frequency of roll changes during continuous production processes.

Features & Benefits

Advanced Material Construction

The PET cloth fabric backing delivers exceptional mechanical properties that surpass conventional paper or film-based masking tapes. This woven construction provides multidirectional strength, preventing tape failure under stress while maintaining flexibility for complex routing applications. The cloth structure also offers superior puncture resistance, protecting against damage from sharp edges or protrusions commonly found in industrial environments.

Heat-Resistant Performance

Engineered for demanding thermal environments, this masking tape maintains its adhesive properties and structural integrity when exposed to elevated temperatures. The heat-resistant formulation prevents adhesive migration, substrate staining, and premature failure that can compromise production quality and operational efficiency. This thermal stability makes the tape suitable for applications involving paint curing ovens, powder coating processes, and other high-temperature manufacturing operations.

Pressure Sensitive Adhesive Technology

The acrylic-based adhesive system provides immediate bond formation upon contact, eliminating the need for activation solvents or curing processes. This pressure sensitive characteristic enables rapid application and repositioning when necessary, improving productivity in fast-paced manufacturing environments. The adhesive maintains consistent performance across varying humidity levels and substrate conditions, ensuring reliable bonding regardless of environmental factors.

Applications & Use Cases

Wire harness manufacturing represents the primary application domain for this specialized tape, where it serves multiple critical functions including conductor bundling, splice protection, and routing guidance. Automotive manufacturers rely on this heat-resistant tape for engine bay applications where exposure to elevated temperatures and automotive fluids demands superior material performance. The clean removal characteristic makes it ideal for temporary masking during painting, coating, and finishing operations across various industrial sectors.

Electronics assembly operations utilize this harness tape for cable management within enclosures, providing strain relief and preventing interference between adjacent conductors. Aerospace applications benefit from the tape's dimensional stability and chemical resistance, particularly in avionic systems where reliability cannot be compromised. HVAC manufacturers incorporate this masking tape in ductwork assembly and insulation installation, where the heat-resistant properties ensure long-term performance in challenging thermal environments.

Industrial maintenance teams find this tape invaluable for temporary repairs and equipment modifications where permanent adhesive solutions would create future servicing complications. The extended length format makes it particularly suitable for continuous production lines and large-scale assembly operations where efficiency and consistency are paramount.

Quality Control & Compliance

Manufacturing processes for this specialized harness tape incorporate rigorous quality control measures to ensure consistent performance characteristics across all production batches. Advanced testing protocols evaluate adhesive strength, temperature resistance, and substrate compatibility using standardized industrial test methods. These comprehensive quality assurance procedures guarantee that each roll meets the demanding specifications required for professional applications.

Environmental compliance considerations are integrated throughout the manufacturing process, with careful attention to sustainable raw material sourcing and responsible production practices. The acrylic adhesive formulation excludes harmful solvents and volatile organic compounds, supporting workplace safety objectives and environmental stewardship initiatives. Regular third-party testing validates ongoing compliance with international quality standards and regulatory requirements relevant to industrial adhesive products.

Batch traceability systems enable comprehensive documentation of material properties and production parameters, facilitating quality investigations and supporting customer-specific certification requirements. This systematic approach to quality management ensures reliable performance and builds confidence among procurement professionals selecting adhesive solutions for critical applications.

Customization & Branding Options

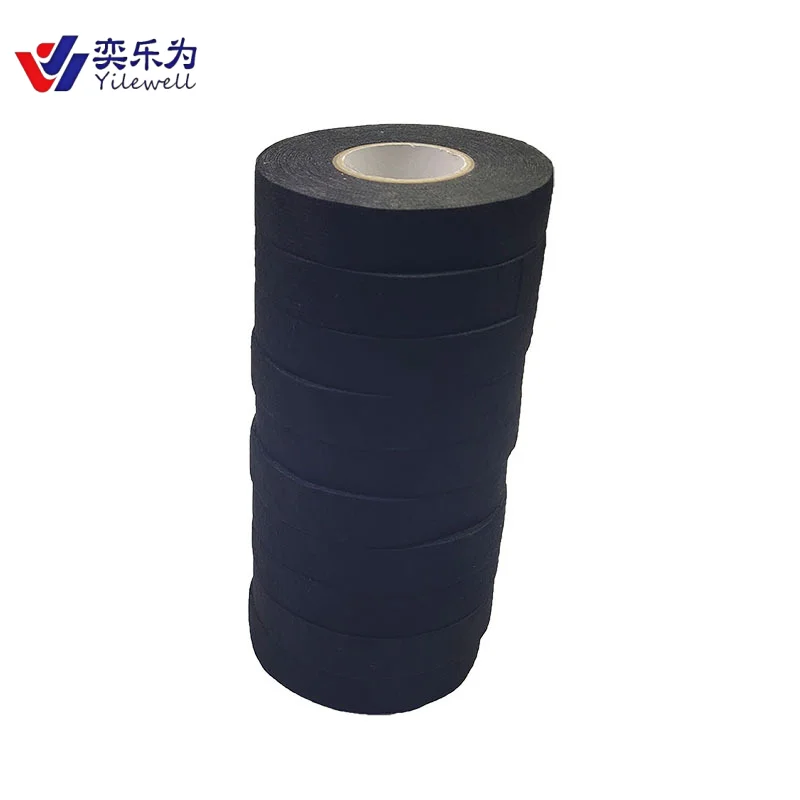

Recognizing the diverse requirements of modern industrial applications, this harness tape platform supports various customization options to meet specific operational needs. Width variations accommodate different bundling requirements and application constraints, while custom length configurations optimize material utilization for specific production volumes. Color options beyond standard configurations enable visual coding systems for complex harness assemblies and quality control applications.

Private label packaging solutions allow distributors and system integrators to present the product under their own branding while maintaining the underlying quality and performance characteristics. Custom packaging formats support specific inventory management requirements and integrate seamlessly with existing supply chain systems. Technical documentation can be customized to include application-specific guidelines and compatibility information relevant to particular industry segments.

Specialized adhesive formulations can be developed for unique environmental conditions or substrate compatibility requirements, leveraging advanced polymer chemistry expertise to address challenging bonding scenarios. These customization capabilities position the product as a flexible platform for OEM applications and specialized industrial requirements.

Packaging & Logistics Support

Professional packaging systems protect product integrity during storage and transportation while optimizing handling efficiency for end users. Moisture barrier packaging prevents environmental degradation of adhesive properties, ensuring consistent performance regardless of storage duration or climatic conditions. Standardized packaging dimensions facilitate efficient warehousing and distribution through existing logistics networks.

Bulk packaging configurations serve high-volume users while maintaining individual roll protection and identification systems. Custom packaging solutions accommodate specific inventory management requirements and integrate with automated dispensing systems used in modern manufacturing facilities. Clear product identification and batch coding systems support inventory rotation procedures and quality traceability requirements.

Global distribution capabilities ensure reliable product availability across international markets, with regional inventory positioning reducing lead times and transportation costs. Comprehensive logistics support includes customs documentation, regulatory compliance assistance, and coordination with local distribution partners to streamline the supply chain for international customers.

Why Choose Us

Our organization brings decades of experience in specialty adhesive development and manufacturing, with a proven track record of serving diverse industrial markets across multiple continents. This extensive experience enables deep understanding of application-specific requirements and the technical challenges facing modern manufacturers. Our global presence facilitates responsive customer support and ensures consistent product availability regardless of geographic location.

Continuous investment in research and development capabilities maintains our position at the forefront of adhesive technology innovation, enabling rapid response to emerging market requirements and evolving regulatory standards. Our comprehensive quality management systems and international certifications demonstrate unwavering commitment to product excellence and customer satisfaction. Collaborative relationships with leading equipment manufacturers and system integrators provide valuable insights into future application trends and technology requirements.

As a recognized metal packaging supplier and custom tin box supplier, our expertise extends beyond adhesive products to comprehensive packaging solutions that complement our core adhesive offerings. This broad capability portfolio enables integrated solutions for complex industrial applications while maintaining the specialized focus that drives innovation in heat-resistant tape technology. Our commitment to sustainable manufacturing practices and environmental responsibility aligns with the growing emphasis on corporate sustainability initiatives across global markets.

Conclusion

The PET Cloth Fabric Single Sided Pressure Sensitive Masking Tape Heat-Resistant Acrylic Adhesive Sticker No Residue 25m harness tape represents a sophisticated solution for demanding industrial applications where conventional masking tapes cannot deliver adequate performance. Its unique combination of heat resistance, clean removal characteristics, and robust construction addresses critical requirements in wire harness manufacturing, automotive assembly, and high-temperature processing applications. The extended length format and professional-grade materials provide exceptional value for operations requiring reliable, consistent bonding performance. This specialized tape continues to set industry standards for heat-resistant masking applications, supporting the evolving needs of modern manufacturing processes while maintaining the quality and reliability that professional users demand.

| item | value |

| Adhesive | Acrylic |

| Use | MASKING |

| Place of Origin | China |

| Adhesive Side | Single Sided |

| Material | Cloth |

| Type | Adhesive Sticker |

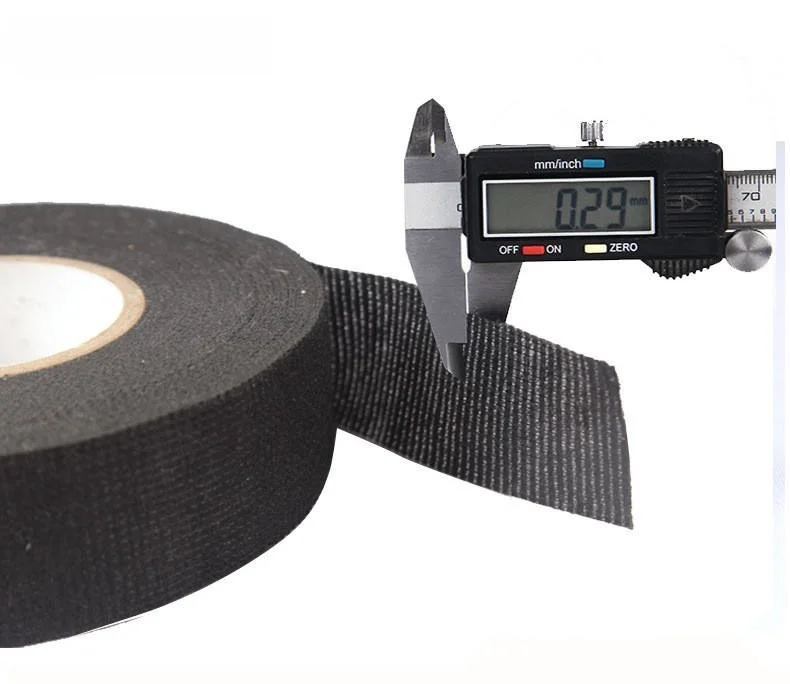

| Thickness | 0.26mm |

| Adhesive Type | Pressure Sensitive |

| Feature | Heat-resistant |

| Brand Name | YLW |

| Model Number | YLW-- B005 |

| Design Printing | No printing |

| cycle length | 25m |

| paper core | No paper core. |

| Printing Handling | No printing |

| glue | Acrylic |

well

1. who are we?

We are based in Jiangsu, China, start from 2025,sell to Mid East(30.00%),Southeast Asia(20.00%),Central America(20.00%),North America(15.00%),South Asia(15.00%). There are total about - people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

automotive tape

4. why should you buy from us not from other suppliers?

-

5. what services can we provide?

Accepted Delivery Terms: -;

Accepted Payment Currency: -;

Accepted Payment Type: -;

Language Spoken: English