Introduction

In the demanding world of automotive manufacturing and electrical system assembly, reliable wire management solutions are essential for maintaining operational integrity and safety standards. The PET Fabric Cloth Wire Harness Tape Masking Single Sided Pressure Sensitive Heat Resistant Automotive Use Acrylic Adhesive represents a breakthrough in protective adhesive technology, specifically engineered to meet the rigorous requirements of modern automotive applications. This advanced masking tape combines the durability of polyethylene terephthalate fabric construction with high-performance acrylic adhesive chemistry, delivering exceptional heat resistance and reliable bonding characteristics that automotive manufacturers and wire harness specialists demand.

As vehicle electrical systems become increasingly complex and operate under more extreme conditions, the need for specialized protective materials has never been greater. This professional-grade masking tape addresses critical challenges in wire harness protection, automotive painting processes, and component masking applications where standard adhesive solutions fail to deliver adequate performance. The single-sided pressure-sensitive design ensures precise application control while maintaining strong adhesion to various automotive substrates, making it an indispensable tool for quality-conscious manufacturers and assembly operations worldwide.

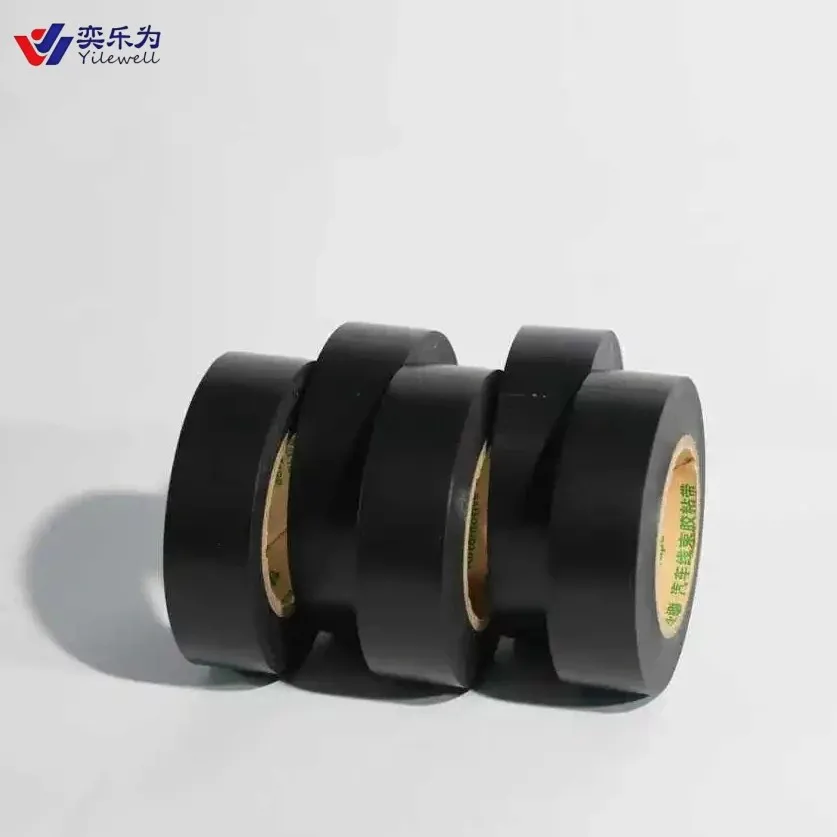

Product Overview

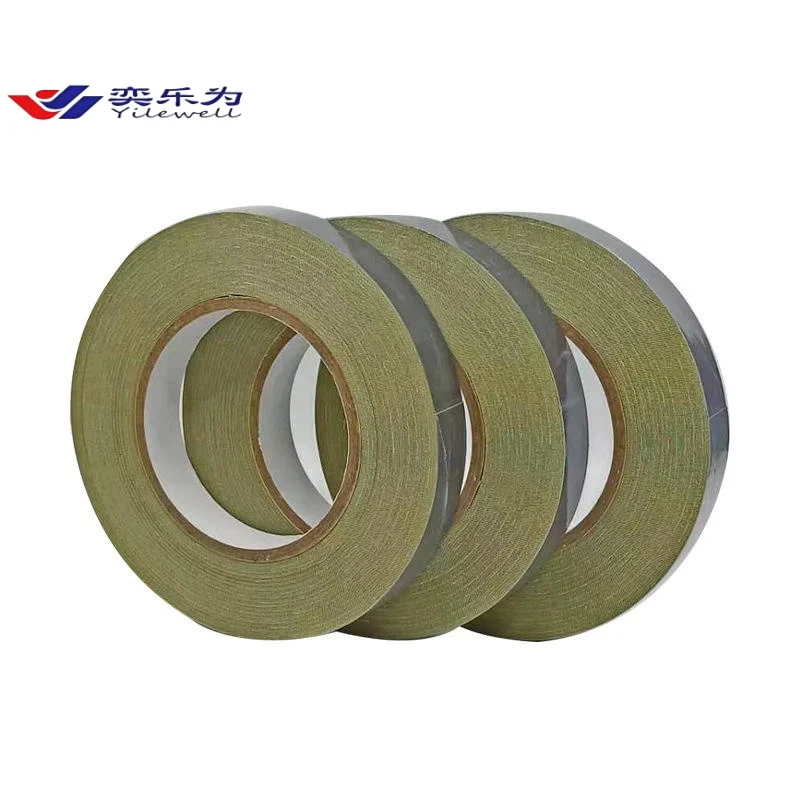

The PET Fabric Cloth Wire Harness Tape Masking Single Sided Pressure Sensitive Heat Resistant Automotive Use Acrylic Adhesive features a sophisticated multi-layer construction that maximizes performance across diverse automotive applications. The foundation of this tape consists of a high-strength polyethylene terephthalate fabric carrier that provides exceptional dimensional stability and tear resistance, essential characteristics for maintaining protection integrity during demanding manufacturing processes. The fabric construction offers superior conformability around irregular surfaces and wire bundle configurations while resisting deformation under mechanical stress.

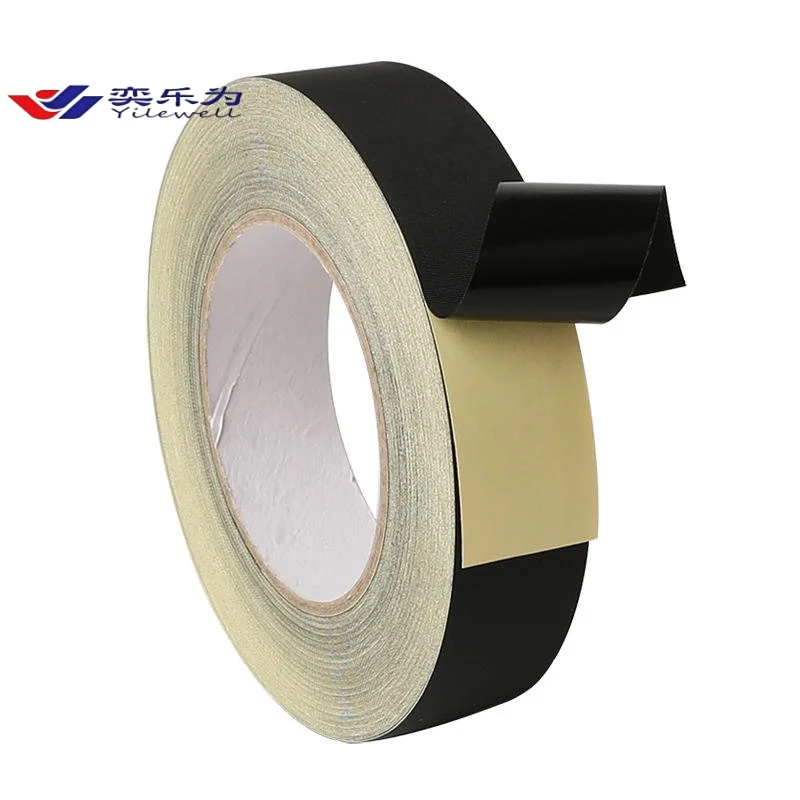

The specialized acrylic adhesive system represents years of development focused on automotive industry requirements. This pressure-sensitive formulation delivers immediate initial tack for efficient application while developing full bond strength over time. The adhesive chemistry is specifically designed to maintain consistent performance across wide temperature ranges, ensuring reliable protection whether applied in ambient assembly conditions or exposed to elevated curing temperatures common in automotive finishing processes. The single-sided configuration provides precise control over adhesive placement, eliminating unwanted adhesion to application tools or adjacent surfaces.

Heat resistance capabilities distinguish this masking tape from conventional automotive adhesive products. The engineered material system maintains structural integrity and adhesive performance when exposed to elevated temperatures encountered in paint baking operations, engine compartment environments, and other thermally challenging automotive applications. This thermal stability ensures that protected wire harnesses and components remain fully shielded throughout demanding manufacturing and service conditions.

Features & Benefits

Advanced Material Construction

The polyethylene terephthalate fabric carrier provides exceptional mechanical properties that translate directly into superior application performance. This engineered fabric construction offers outstanding puncture resistance, preventing damage during handling and installation processes. The material's inherent flexibility allows it to conform closely to complex geometries and irregular surfaces common in automotive wire harness assemblies, ensuring complete coverage and protection. The fabric structure also provides excellent dimensional stability, maintaining its protective barrier properties even under mechanical stress or temperature cycling conditions.

Superior Adhesive Performance

The acrylic adhesive system delivers exceptional bonding characteristics across a wide range of automotive substrates including metals, plastics, rubber, and painted surfaces. This broad substrate compatibility makes the tape suitable for diverse masking applications without requiring surface-specific adhesive formulations. The pressure-sensitive nature ensures immediate tack upon application, eliminating waiting periods and improving manufacturing efficiency. The adhesive maintains consistent performance throughout its service life, providing reliable protection without adhesive migration or degradation that could compromise protected surfaces.

Thermal Management Capabilities

Heat resistance represents a critical performance advantage in automotive applications where elevated temperatures are common. The PET Fabric Cloth Wire Harness Tape Masking Single Sided Pressure Sensitive Heat Resistant Automotive Use Acrylic Adhesive maintains its protective properties and adhesive integrity when exposed to the thermal conditions encountered in automotive manufacturing processes. This thermal stability ensures that wire harnesses and sensitive components remain fully protected during paint curing, welding operations, and other high-temperature processes without tape failure or adhesive residue formation.

Applications & Use Cases

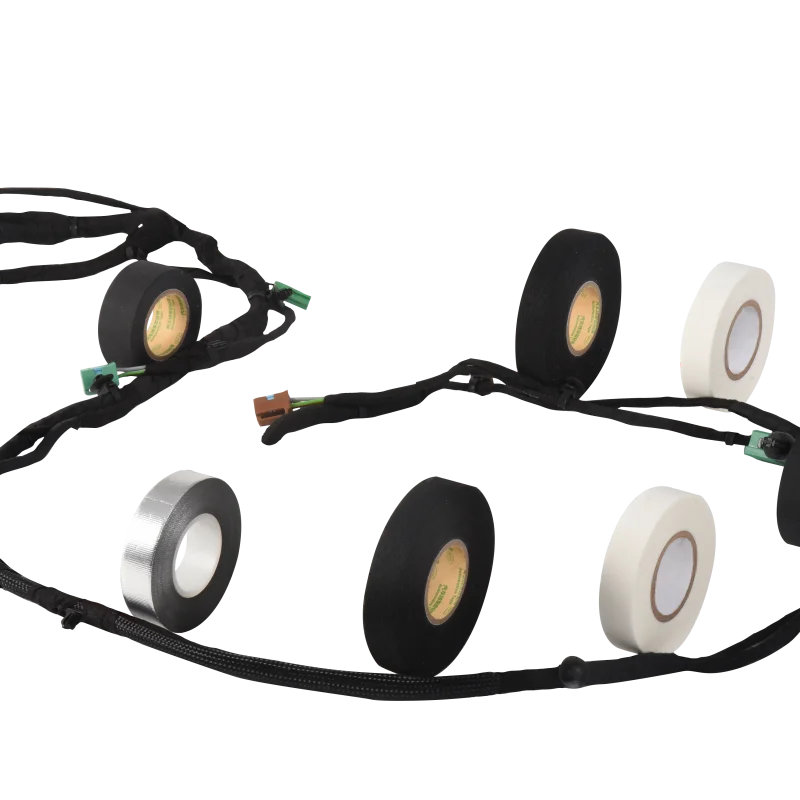

Automotive wire harness protection represents the primary application domain for this specialized masking tape. During vehicle assembly, complex wire harness systems require protection from paint overspray, welding spatter, and chemical exposure that could compromise electrical performance or safety. The tape's conformable fabric construction allows it to wrap securely around wire bundles of varying diameters while maintaining consistent coverage. The heat-resistant properties ensure that harnesses remain protected throughout paint booth operations and other thermal processes common in automotive manufacturing.

Component masking during automotive finishing operations benefits significantly from this tape's specialized performance characteristics. Sensitive electronic components, connectors, and precision assemblies require reliable protection from coating materials and chemical exposure. The single-sided pressure-sensitive design allows precise application around complex component geometries while the acrylic adhesive ensures secure bonding to various substrate materials. The clean removal characteristics prevent adhesive residue formation that could interfere with subsequent assembly operations or component functionality.

Engine compartment applications present unique challenges that this masking tape is specifically designed to address. The combination of elevated temperatures, vibration, and chemical exposure in engine bay environments demands exceptional material performance. The PET fabric construction provides mechanical durability while the heat-resistant adhesive maintains bonding integrity under these demanding conditions. This makes the tape ideal for protecting sensitive components during engine assembly, maintenance operations, and retrofit installations where temporary protection is required.

Aerospace and heavy equipment industries also benefit from this tape's advanced performance characteristics. The demanding requirements of these sectors, including exposure to extreme temperatures, chemicals, and mechanical stress, align perfectly with the tape's engineered capabilities. Applications in aircraft wire harness protection, industrial equipment masking, and marine electrical system protection demonstrate the versatility and reliability of this specialized adhesive solution.

Quality Control & Compliance

Manufacturing excellence begins with rigorous quality control processes that ensure every roll of PET Fabric Cloth Wire Harness Tape Masking Single Sided Pressure Sensitive Heat Resistant Automotive Use Acrylic Adhesive meets exacting performance standards. Advanced testing protocols evaluate adhesive consistency, heat resistance characteristics, dimensional stability, and substrate compatibility across representative automotive materials. These comprehensive quality assurance measures ensure that end users receive products that perform reliably in demanding automotive applications.

Environmental compliance represents a fundamental aspect of product development and manufacturing processes. The tape formulation and production methods align with international environmental standards and automotive industry sustainability initiatives. Material selection prioritizes low-emission components while manufacturing processes minimize environmental impact through efficient resource utilization and waste reduction strategies. This commitment to environmental responsibility ensures that the product supports sustainable manufacturing practices throughout the automotive supply chain.

Automotive industry certification requirements drive continuous improvement in product performance and reliability. The tape undergoes extensive validation testing that simulates real-world automotive applications including thermal cycling, chemical exposure, and mechanical stress conditions. These validation processes ensure compatibility with automotive OEM requirements and aftermarket quality standards. Documentation and traceability systems support customer quality requirements and facilitate seamless integration into existing manufacturing processes.

Customization & Branding Options

Recognition that automotive applications often require specialized configurations drives comprehensive customization capabilities for the PET Fabric Cloth Wire Harness Tape Masking Single Sided Pressure Sensitive Heat Resistant Automotive Use Acrylic Adhesive. Width variations accommodate different wire harness sizes and application requirements while maintaining consistent performance characteristics across all configurations. Length options support both high-volume production applications and specialized low-volume requirements without compromising material quality or performance.

Adhesive strength modifications allow optimization for specific substrate combinations and application conditions. Standard formulations provide excellent general-purpose performance while specialized variants offer enhanced bonding for challenging surfaces or improved removability for temporary protection applications. These customization options ensure optimal performance across diverse automotive applications without requiring end users to compromise on specific performance requirements.

Private labeling and custom packaging solutions support distributor and OEM branding requirements. Professional packaging design and labeling options reinforce brand identity while providing clear product identification and application guidance. Custom core sizes and packaging configurations optimize storage and dispensing efficiency for specific production environments. These branding and packaging customization options support marketing objectives while maintaining the high-quality presentation that professional customers expect.

Packaging & Logistics Support

Efficient packaging solutions ensure that the PET Fabric Cloth Wire Harness Tape Masking Single Sided Pressure Sensitive Heat Resistant Automotive Use Acrylic Adhesive arrives in optimal condition for immediate use. Protective packaging prevents contamination and mechanical damage during shipping and storage while maintaining the tape's pressure-sensitive adhesive properties. Moisture barrier packaging protects against humidity exposure that could compromise adhesive performance, particularly important for international shipping and extended storage periods.

Logistics optimization supports global distribution requirements through strategic packaging design and shipping configurations. Standardized packaging dimensions maximize shipping efficiency while protective packaging systems ensure product integrity throughout international transportation. Documentation packages include technical data sheets, application guides, and safety information in multiple languages to support global market requirements. These comprehensive logistics solutions minimize delivery times and ensure that customers receive products ready for immediate deployment.

Inventory management support includes flexible packaging configurations that optimize storage efficiency for different customer requirements. Bulk packaging options reduce per-unit costs for high-volume users while smaller packaging configurations support customers with limited storage capacity or diverse application requirements. Lot tracking and expiration date management systems ensure product freshness and support quality management requirements. These logistics support capabilities help customers optimize their supply chain efficiency while maintaining consistent product availability.

Why Choose Us

Our organization brings decades of experience in developing specialized adhesive solutions for demanding industrial applications, with particular expertise in automotive and aerospace markets. This extensive experience translates into deep understanding of customer requirements and the technical challenges that drive product development priorities. Our international market presence spans multiple continents, supporting global customers with consistent product quality and technical support services. This worldwide reach demonstrates our commitment to serving diverse markets while maintaining the highest standards of product excellence and customer service.

Collaboration with leading automotive manufacturers and tier-one suppliers has shaped our product development approach, ensuring that solutions like the PET Fabric Cloth Wire Harness Tape Masking Single Sided Pressure Sensitive Heat Resistant Automotive Use Acrylic Adhesive address real-world application challenges. This industry collaboration provides insights into emerging requirements and technology trends that influence future product development. Our multi-industry expertise extends beyond automotive applications to include aerospace, electronics, and industrial markets, providing broad perspective on adhesive technology applications and performance requirements.

As a recognized metal packaging supplier and custom tin box supplier, our company understands the importance of protective packaging and component masking across diverse industries. This expertise in sustainable tin containers and premium metal boxes provides valuable insights into material protection requirements that influence our adhesive product development. Our position as an established metal packaging manufacturer ensures comprehensive understanding of manufacturing processes and quality requirements that benefit all our product lines. These diverse capabilities as both an OEM tin packaging solutions provider and specialized adhesive manufacturer create unique synergies that benefit our customers.

Conclusion

The PET Fabric Cloth Wire Harness Tape Masking Single Sided Pressure Sensitive Heat Resistant Automotive Use Acrylic Adhesive represents the culmination of advanced materials engineering and deep understanding of automotive application requirements. This specialized masking tape delivers exceptional performance characteristics that address the most demanding challenges in wire harness protection, component masking, and automotive manufacturing processes. The combination of polyethylene terephthalate fabric construction, high-performance acrylic adhesive, and heat-resistant properties creates a solution that exceeds conventional masking tape capabilities while maintaining the ease of use that manufacturing operations require. From protecting complex wire harness assemblies during paint operations to masking sensitive electronic components in engine compartment applications, this advanced adhesive solution provides reliable performance that automotive professionals can depend on. The comprehensive customization options, quality assurance processes, and global logistics support ensure that customers receive products perfectly suited to their specific requirements while maintaining the consistent quality that demanding automotive applications require.

| item | value |

| Adhesive | Acrylic |

| Use | MASKING |

| Place of Origin | China |

| Adhesive Side | Single Sided |

| Material | Cloth |

| Type | Adhesive Sticker |

| Thickness | 0.26mm |

| Adhesive Type | Pressure Sensitive |

| Feature | Heat-resistant |

| Brand Name | YLW |

| Model Number | YLW-- B005 |

| Design Printing | No printing |

| cycle length | 25m |

| paper core | No paper core. |

| Printing Handling | No printing |

| glue | Acrylic |

well

1. who are we?

We are based in Jiangsu, China, start from 2025,sell to Mid East(30.00%),Southeast Asia(20.00%),Central America(20.00%),North America(15.00%),South Asia(15.00%). There are total about - people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

automotive tape

4. why should you buy from us not from other suppliers?

-

5. what services can we provide?

Accepted Delivery Terms: -;

Accepted Payment Currency: -;

Accepted Payment Type: -;

Language Spoken: English