Introduction

In today's demanding industrial landscape, professionals across manufacturing, electronics, and construction sectors require reliable adhesive solutions that can withstand extreme conditions while maintaining superior performance. The Single-Sided Pressure Sensitive Heat-Resistant Acrylic Adhesive Insulation Tape Masking Use Thickness represents a breakthrough in specialized tape technology, offering unmatched durability and versatility for critical applications. This innovative adhesive solution combines advanced acrylic chemistry with precision engineering to deliver exceptional bonding strength, thermal stability, and chemical resistance in the most challenging environments.

Designed for professionals who demand excellence, this pressure-sensitive adhesive tape addresses the growing need for reliable insulation and masking solutions in high-temperature applications. Whether used in automotive manufacturing, electronic device assembly, or industrial equipment maintenance, this specialized tape provides consistent performance that professionals can trust. The unique formulation ensures optimal adhesion while allowing for clean removal when temporary applications are required, making it an indispensable tool for quality-conscious operations worldwide.

Product Overview

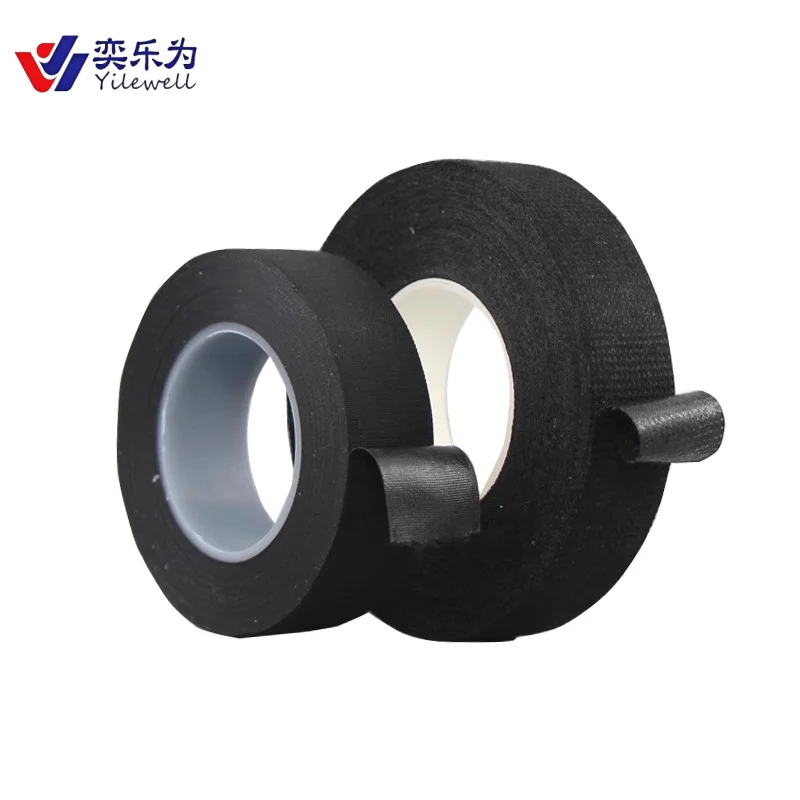

The Single-Sided Pressure Sensitive Heat-Resistant Acrylic Adhesive Insulation Tape Masking Use Thickness showcases cutting-edge adhesive technology specifically engineered for demanding industrial applications. This specialized tape features a robust acrylic adhesive system that maintains its bonding properties across a wide temperature range, ensuring reliable performance in both ambient and elevated temperature conditions. The single-sided design provides targeted adhesion while maintaining flexibility and conformability to various substrate surfaces.

Built upon years of adhesive science research and development, this insulation tape incorporates premium materials that resist degradation from heat exposure, UV radiation, and common industrial chemicals. The carefully calibrated thickness ensures optimal balance between flexibility and structural integrity, allowing the tape to conform to irregular surfaces while maintaining sufficient strength for demanding applications. This thoughtful engineering approach results in a product that meets the rigorous requirements of modern manufacturing and maintenance operations.

Features & Benefits

Advanced Acrylic Adhesive Technology

The heart of this Single-Sided Pressure Sensitive Heat-Resistant Acrylic Adhesive Insulation Tape Masking Use Thickness lies in its sophisticated acrylic adhesive formulation. Unlike conventional adhesives that may fail under thermal stress, this advanced system maintains consistent bonding strength even when exposed to elevated temperatures. The pressure-sensitive nature ensures immediate adhesion upon application, eliminating the need for heat activation or chemical curing processes that can complicate field applications.

This innovative adhesive chemistry provides excellent adhesion to a wide variety of substrates, including metals, plastics, ceramics, and composite materials. The formulation resists cold flow and creep, maintaining dimensional stability throughout its service life. Additionally, the adhesive demonstrates superior resistance to plasticizer migration, preventing degradation when used with vinyl and other polymer substrates commonly found in industrial applications.

Superior Heat Resistance Performance

The exceptional thermal stability of this insulation tape sets it apart from standard masking solutions. The carefully engineered polymer backbone and cross-linking chemistry ensure that the tape maintains its physical and adhesive properties when exposed to sustained high temperatures. This heat resistance capability makes it ideal for applications involving paint curing ovens, welding operations, and electronic component manufacturing where thermal cycling is common.

Beyond simple heat resistance, the tape demonstrates excellent thermal shock resistance, maintaining its integrity when subjected to rapid temperature changes. This characteristic proves invaluable in applications where components experience frequent heating and cooling cycles, such as automotive paint processes or electronic assembly operations where selective heating is employed.

Precision Thickness Engineering

The precisely controlled thickness of this Single-Sided Pressure Sensitive Heat-Resistant Acrylic Adhesive Insulation Tape Masking Use Thickness provides optimal performance characteristics for professional applications. This careful dimensional control ensures consistent handling properties, predictable unwind characteristics, and uniform adhesive distribution across the tape width. The engineered thickness also contributes to the tape's ability to conform to surface irregularities while maintaining sufficient structural integrity for demanding applications.

This thickness optimization also enhances the tape's insulation properties, providing effective electrical and thermal barriers where required. The balanced construction prevents excessive bulk while ensuring adequate protection and masking coverage, making it suitable for precision applications where dimensional control is critical.

Applications & Use Cases

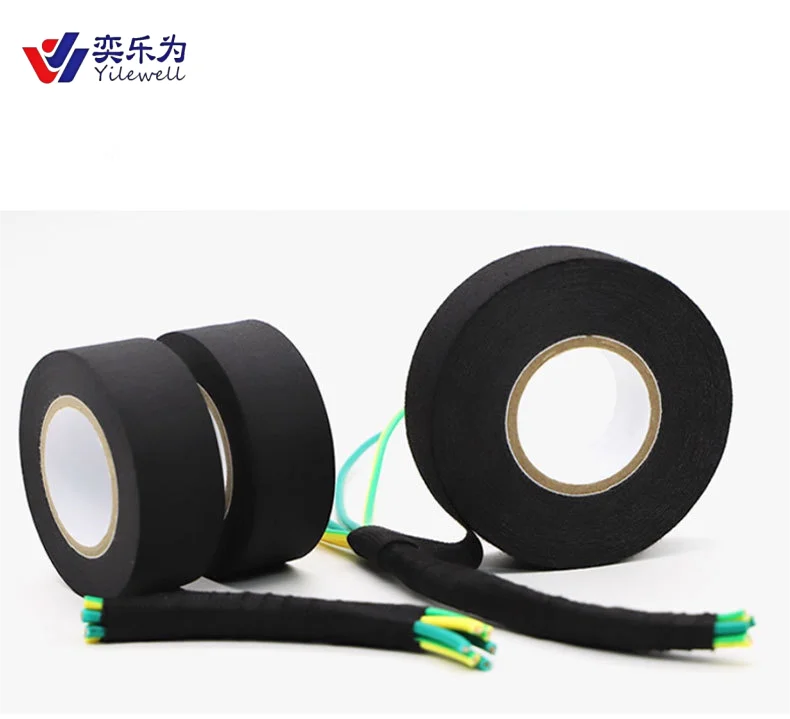

The versatility of this Single-Sided Pressure Sensitive Heat-Resistant Acrylic Adhesive Insulation Tape Masking Use Thickness makes it indispensable across numerous industries and applications. In electronics manufacturing, the tape serves as an essential component for protecting sensitive areas during soldering, wave soldering, and conformal coating processes. Its heat resistance ensures that protective barriers remain intact throughout high-temperature assembly operations, preventing contamination and ensuring product quality.

Automotive manufacturing facilities rely on this specialized tape for paint masking applications where components must withstand oven curing temperatures. The tape's ability to create sharp, clean paint lines while resisting thermal degradation makes it ideal for multi-stage painting processes. Additionally, its chemical resistance properties ensure compatibility with the various solvents and cleaning agents commonly used in automotive production environments.

In industrial maintenance and repair operations, this insulation tape provides reliable temporary protection for equipment components during welding, grinding, and surface treatment processes. Its conformability allows it to follow complex contours and provide effective shielding against sparks, debris, and chemical exposure. The clean removal characteristics ensure that temporary protective applications don't leave adhesive residue that could compromise subsequent operations or equipment performance.

Construction and building trades utilize this tape for HVAC applications, electrical insulation, and temporary sealing during various installation processes. The tape's moisture resistance and thermal stability make it suitable for both interior and exterior applications where environmental exposure is a concern. Its pressure-sensitive adhesive ensures reliable bonding to construction materials while allowing for repositioning during installation phases.

Quality Control & Compliance

Manufacturing excellence drives every aspect of this Single-Sided Pressure Sensitive Heat-Resistant Acrylic Adhesive Insulation Tape Masking Use Thickness production process. Advanced quality control systems monitor critical parameters throughout manufacturing to ensure consistent product performance and reliability. Raw material verification, in-process testing, and final product validation combine to deliver tape that meets the demanding requirements of professional users across diverse industries.

Environmental and safety compliance represents a core commitment in the development and production of this specialized tape. The adhesive formulation incorporates environmentally responsible chemistry while maintaining superior performance characteristics. Regular testing ensures compliance with relevant international standards for adhesive products, providing users with confidence in both performance and regulatory compliance for their applications.

Rigorous testing protocols evaluate the tape's performance under various environmental conditions, including temperature cycling, humidity exposure, and chemical compatibility assessments. These comprehensive testing programs ensure that the product delivers consistent performance across the wide range of conditions encountered in real-world applications, providing users with reliable performance data for their specific use cases.

Customization & Branding Options

Understanding that different applications require specific performance characteristics, this Single-Sided Pressure Sensitive Heat-Resistant Acrylic Adhesive Insulation Tape Masking Use Thickness can be customized to meet unique requirements. Width variations accommodate different application needs, from narrow precision masking to wide-area coverage applications. Custom lengths and packaging configurations help optimize inventory management and reduce waste in high-volume operations.

Color customization options enable integration with existing quality control and identification systems used by manufacturing facilities. Custom colors can help differentiate between different tape specifications or application areas, reducing the risk of application errors in complex manufacturing environments. These customization capabilities ensure that the tape integrates seamlessly into existing operational procedures and quality management systems.

Private labeling and custom packaging services support distributor and end-user branding requirements. Custom packaging solutions can incorporate user-specific handling instructions, application guidelines, and safety information tailored to specific industries or applications. This flexibility enables seamless integration into existing supply chain and inventory management systems while maintaining brand consistency throughout the organization.

Packaging & Logistics Support

Efficient packaging design ensures that this Single-Sided Pressure Sensitive Heat-Resistant Acrylic Adhesive Insulation Tape Masking Use Thickness arrives in optimal condition while minimizing environmental impact. Protective packaging prevents contamination and physical damage during shipping and storage, while compact designs reduce transportation costs and storage space requirements. The packaging systems are designed to maintain product integrity throughout the entire distribution chain, from manufacturing facility to end-user application.

Logistics optimization includes packaging configurations that maximize shipping efficiency while ensuring easy handling at the destination. Standardized packaging dimensions facilitate efficient warehouse operations and inventory management, while clear labeling systems provide essential product identification and handling information. These logistics considerations help reduce total cost of ownership while ensuring reliable product availability when needed.

Environmental responsibility extends to packaging design, incorporating recyclable materials where possible while maintaining necessary protection levels. Packaging optimization reduces waste throughout the supply chain, supporting sustainability initiatives while maintaining the product protection standards required for this specialized adhesive tape. This balanced approach ensures environmental responsibility without compromising product quality or user convenience.

Why Choose Us

With extensive experience serving global markets across multiple industries, our organization brings deep expertise in adhesive technology and application engineering to every product development initiative. This Single-Sided Pressure Sensitive Heat-Resistant Acrylic Adhesive Insulation Tape Masking Use Thickness represents the culmination of years of research, development, and real-world application feedback from professional users worldwide. Our commitment to continuous improvement ensures that products evolve to meet changing industry requirements and emerging application challenges.

As a recognized custom tin box supplier and metal packaging manufacturer, our company leverages diverse manufacturing capabilities and quality systems that extend across multiple product categories. This multi-industry expertise enables us to understand the unique challenges faced by different sectors and develop solutions that address specific application requirements. Our global collaboration network ensures access to the latest adhesive technologies and manufacturing innovations, resulting in products that consistently exceed user expectations.

The combination of advanced manufacturing capabilities, rigorous quality control systems, and comprehensive technical support creates a partnership approach that goes beyond simple product supply. Our team works closely with users to understand application requirements and provide technical guidance that ensures optimal product performance. This collaborative approach has established long-term relationships with leading companies across industries who rely on our expertise for their critical adhesive tape requirements.

Conclusion

The Single-Sided Pressure Sensitive Heat-Resistant Acrylic Adhesive Insulation Tape Masking Use Thickness stands as a testament to advanced adhesive engineering and manufacturing excellence. Its unique combination of thermal resistance, chemical compatibility, and precision thickness control makes it an invaluable tool for professionals across diverse industries who demand reliable performance in challenging applications. From electronics manufacturing to automotive production, from industrial maintenance to construction applications, this specialized tape consistently delivers the performance characteristics that quality-conscious operations require.

The investment in advanced acrylic adhesive technology, combined with rigorous quality control and comprehensive customization capabilities, ensures that this product meets the evolving needs of modern industrial applications. Its proven track record in demanding environments, supported by continuous improvement initiatives and global technical support, establishes it as a preferred solution for organizations that prioritize quality, reliability, and operational excellence in their adhesive tape requirements.

| item | value |

| Adhesive | Acrylic |

| Use | MASKING |

| Place of Origin | China |

| Adhesive Side | Single Sided |

| Material | Flannel |

| Type | Insulation Tape |

| Thickness | 0.3mm |

| Adhesive Type | Pressure Sensitive |

| Feature | Heat-resistant |

| Brand Name | YLW |

| Model Number | YLW-R001 |

| Design Printing | Offer Printing |

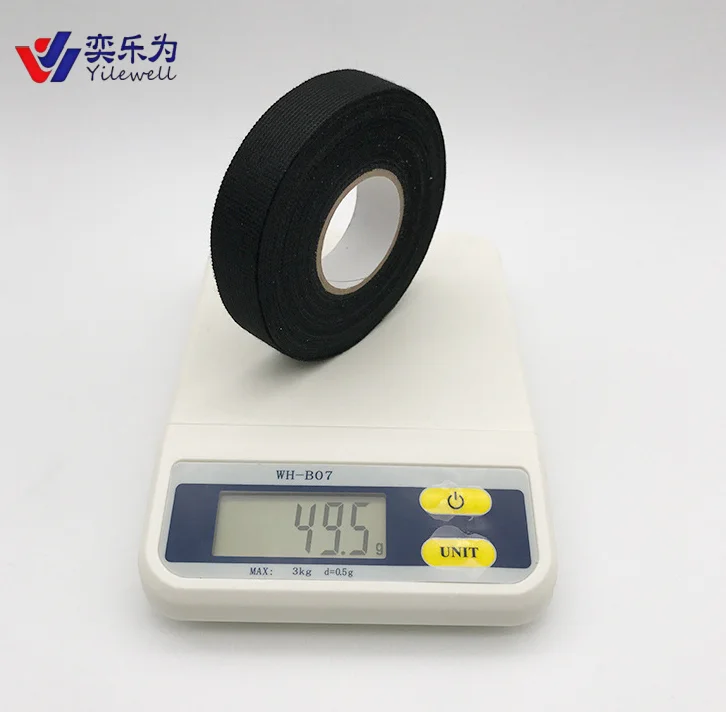

| cycle length | 10m |

| paper core | Customizable |

| Printing Handling | Offer printing |

| glue | Acrylic |

well

1. who are we?

We are based in Jiangsu, China, start from 2025,sell to Mid East(30.00%),Southeast Asia(20.00%),Central America(20.00%),North America(15.00%),South Asia(15.00%). There are total about - people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

automotive tape

4. why should you buy from us not from other suppliers?

-

5. what services can we provide?

Accepted Delivery Terms: -;

Accepted Payment Currency: -;

Accepted Payment Type: -;

Language Spoken: English