Introduction

In the demanding world of automotive wiring and electrical system protection, professionals require specialized materials that can withstand extreme conditions while maintaining optimal adhesion and reliability. The Waterproof Heat-Resistant Single-Sided Pressure Sensitive Acrylic Adhesive Sticker Auto Wiring Masking Cloth Fabric Wrap Harness represents a breakthrough in protective wrapping technology, specifically engineered for automotive electrical applications. This advanced cloth fabric wrap combines superior waterproofing capabilities with exceptional heat resistance, creating an ideal solution for protecting wire harnesses, cable assemblies, and sensitive electrical components in challenging environments.

Automotive technicians, manufacturing engineers, and electrical system specialists worldwide recognize the critical importance of proper wire harness protection in maintaining vehicle performance and safety. Traditional masking solutions often fail under extreme temperature fluctuations, moisture exposure, or mechanical stress, leading to compromised electrical systems and costly repairs. This innovative fabric wrap harness technology addresses these challenges by incorporating premium acrylic adhesive chemistry with specially woven cloth materials, delivering unmatched protection for automotive wiring applications across diverse operating conditions.

Product Overview

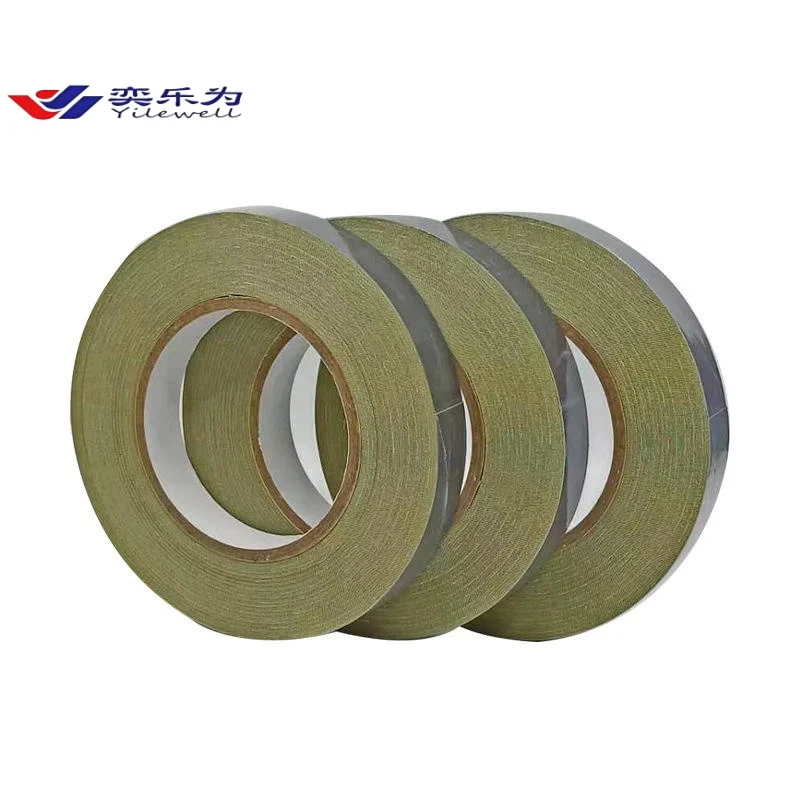

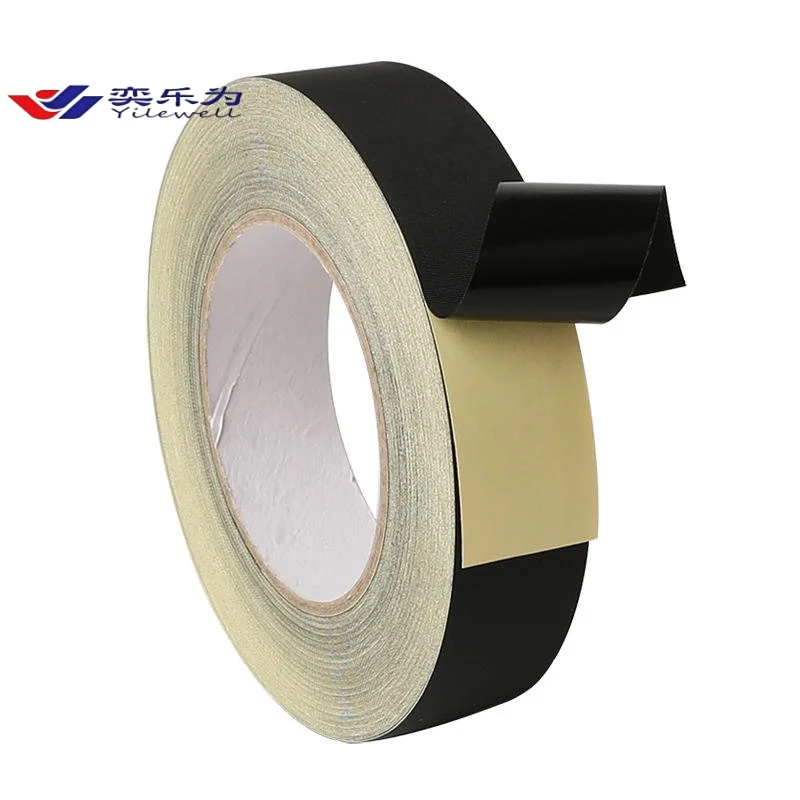

The Waterproof Heat-Resistant Single-Sided Pressure Sensitive Acrylic Adhesive Sticker Auto Wiring Masking Cloth Fabric Wrap Harness features a sophisticated multi-layer construction designed to excel in automotive environments. The foundation consists of a high-performance cloth fabric substrate that provides excellent mechanical strength and flexibility, allowing for easy application around complex wire routing configurations. This textile base material undergoes specialized treatment processes to enhance its resistance to automotive fluids, temperature extremes, and environmental contaminants.

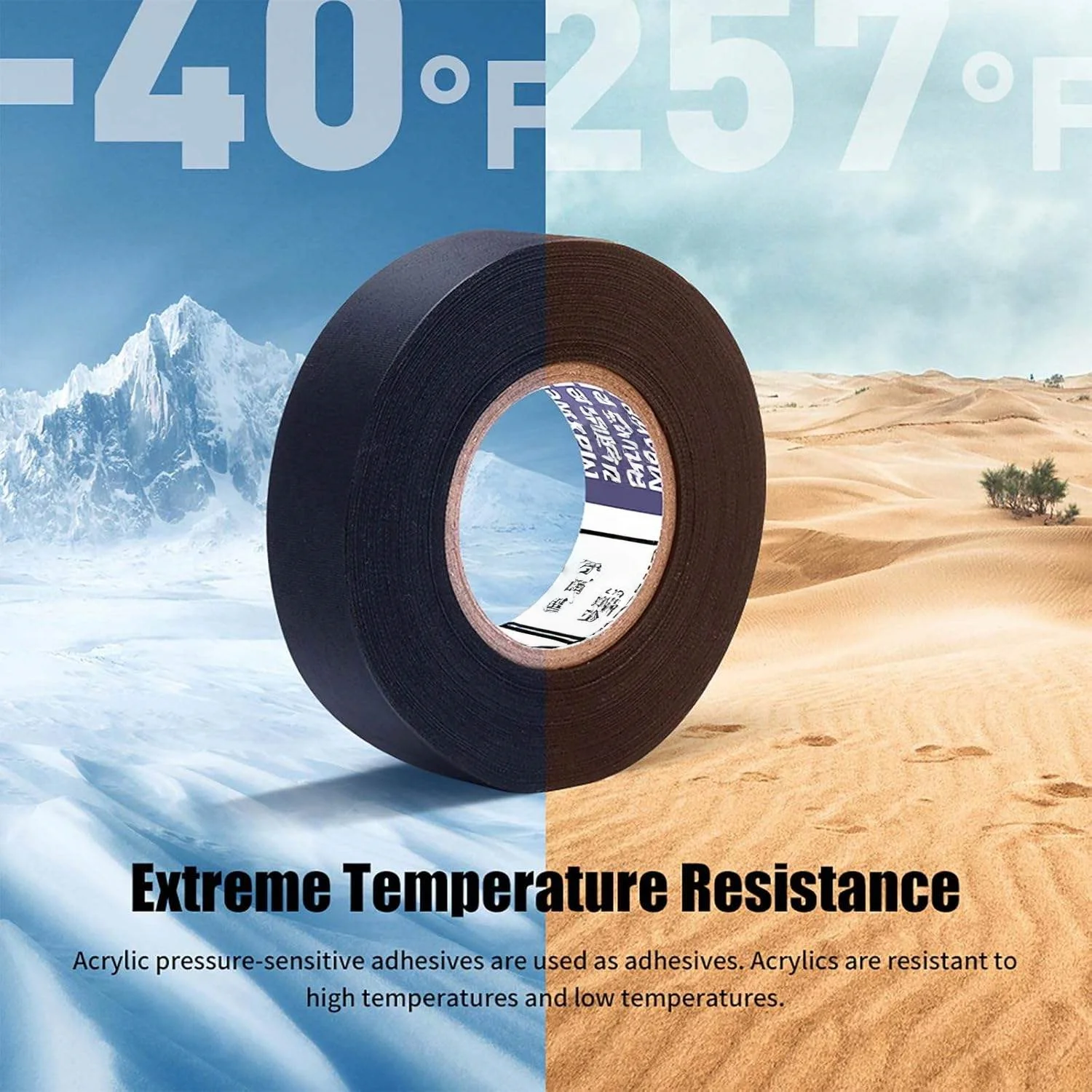

The pressure-sensitive acrylic adhesive system employed in this masking cloth fabric wrap delivers exceptional bonding performance across a wide range of substrates commonly found in automotive applications. Unlike conventional rubber-based adhesives that can degrade under heat exposure or become brittle in cold conditions, the acrylic formulation maintains consistent adhesion properties throughout extended temperature cycles. This reliability ensures that the protective wrap remains securely positioned throughout the vehicle's operational life, providing continuous protection for critical wiring systems.

The single-sided configuration optimizes the product for wrapping applications where controlled adhesion is essential. The non-adhesive backing surface facilitates smooth installation while preventing unwanted sticking during the wrapping process. This design consideration significantly reduces installation time and improves the overall quality of wire harness protection installations, making it an ideal choice for both production line applications and field service operations.

Features & Benefits

Advanced Waterproofing Technology

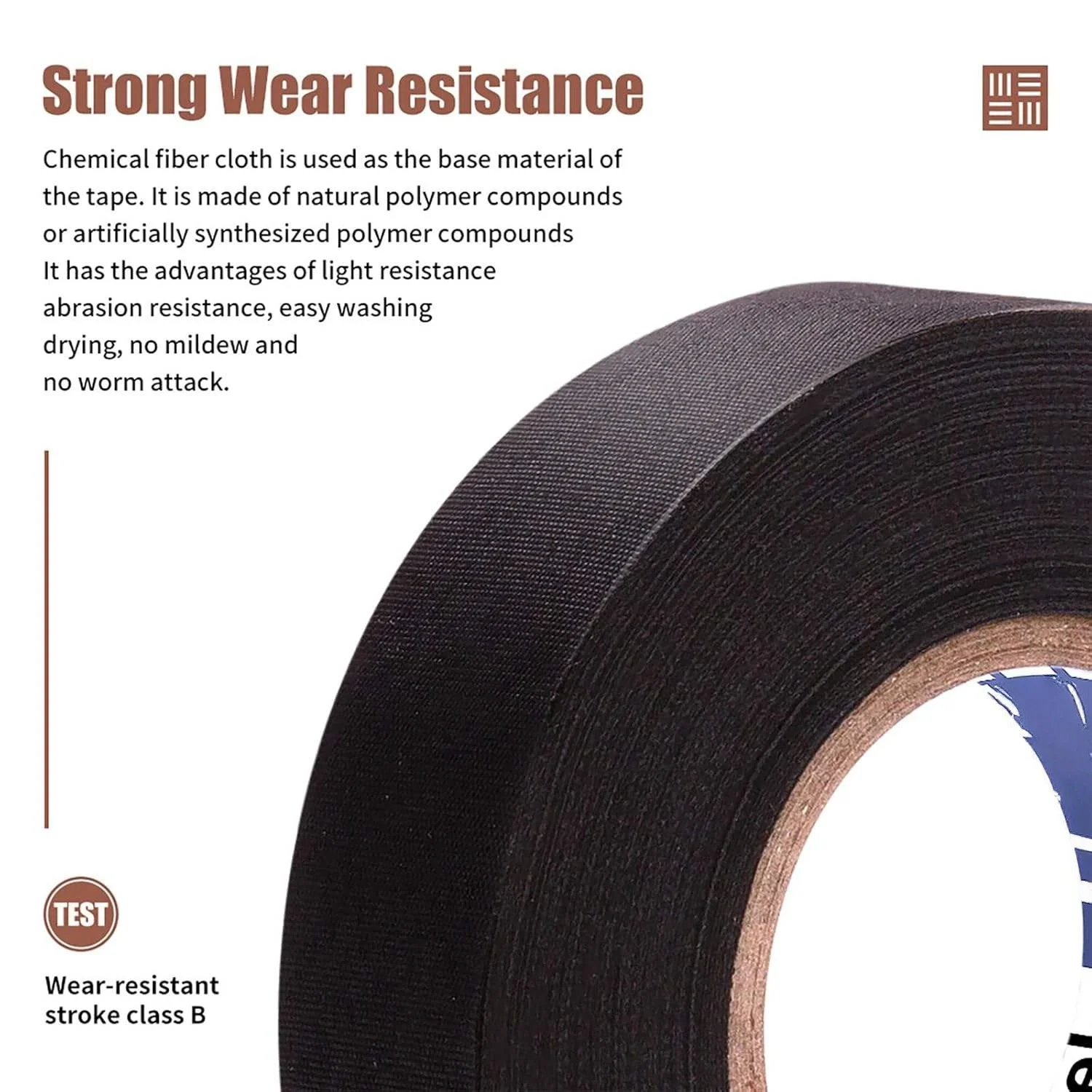

The waterproof characteristics of this auto wiring masking cloth fabric wrap stem from its engineered barrier properties that effectively prevent moisture infiltration into protected wire harnesses. The specialized fabric weave structure, combined with surface treatments, creates multiple defense layers against water intrusion, condensation, and humidity-related degradation. This protection proves particularly valuable in engine compartments, undercarriage installations, and marine automotive applications where exposure to water and corrosive substances poses ongoing threats to electrical system integrity.

Superior Heat Resistance Performance

Heat resistance represents a cornerstone feature of this Waterproof Heat-Resistant Single-Sided Pressure Sensitive Acrylic Adhesive Sticker Auto Wiring Masking Cloth Fabric Wrap Harness, enabling reliable operation in high-temperature automotive environments. The carefully selected materials and construction methods ensure that both the fabric substrate and acrylic adhesive maintain their protective properties when exposed to engine heat, exhaust system proximity, and other thermal challenges. This thermal stability prevents adhesive migration, fabric degradation, and loss of protective effectiveness that commonly affects inferior wrapping materials.

Pressure-Sensitive Application Convenience

The pressure-sensitive adhesive technology eliminates the need for additional heating, solvents, or curing processes during installation, streamlining the application procedure for automotive technicians. This convenience factor translates into reduced labor costs, improved installation consistency, and enhanced productivity in both manufacturing and service environments. The adhesive activates through applied pressure, creating immediate bonding that allows for position adjustments during the initial installation phase while developing full adhesion strength over time.

Applications & Use Cases

Automotive wire harness protection represents the primary application domain for this specialized masking cloth fabric wrap, encompassing everything from engine bay wiring to interior electrical system organization. The material excels in protecting main power distribution harnesses, sensor wiring bundles, communication cables, and auxiliary electrical systems from environmental damage, abrasion, and electromagnetic interference. Its flexibility allows for conforming to complex routing paths while maintaining consistent protection coverage throughout the entire harness length.

Manufacturing applications benefit significantly from the efficiency and reliability characteristics of this auto wiring masking solution. Production facilities utilize the material for protecting partially completed assemblies during manufacturing processes, temporary masking during painting or coating operations, and permanent installation in finished products. The pressure-sensitive nature enables rapid application by assembly line workers while ensuring consistent quality across large production volumes.

Maintenance and repair operations find particular value in the Waterproof Heat-Resistant Single-Sided Pressure Sensitive Acrylic Adhesive Sticker Auto Wiring Masking Cloth Fabric Wrap Harness for field installations and emergency repairs. The material's ability to conform to existing wire harness configurations without requiring disassembly makes it ideal for retrofit applications, repair procedures, and system modifications. Service technicians appreciate the clean application process and reliable long-term performance that reduces callback requirements and warranty claims.

Beyond traditional automotive applications, this versatile fabric wrap harness finds use in marine, agricultural, construction, and industrial equipment where similar environmental challenges exist. The combination of waterproofing, heat resistance, and mechanical durability makes it suitable for protecting electrical systems in boats, farm machinery, construction equipment, and manufacturing automation systems where exposure to harsh operating conditions is commonplace.

Quality Control & Compliance

Stringent quality control measures govern every aspect of production for this auto wiring masking cloth fabric wrap, ensuring consistent performance characteristics that meet the demanding requirements of automotive applications. Advanced testing protocols evaluate adhesion strength, temperature resistance, waterproof integrity, and long-term durability under accelerated aging conditions. These comprehensive quality assurance procedures guarantee that each production batch maintains the high standards expected by automotive manufacturers and service professionals.

Material composition and manufacturing processes align with international automotive industry standards, addressing environmental regulations, safety requirements, and performance specifications established by leading vehicle manufacturers. The acrylic adhesive formulation specifically avoids materials that could outgas harmful compounds or contribute to interior air quality concerns, making it suitable for use throughout vehicle electrical systems without restriction.

Traceability systems maintain detailed records of raw material sources, production parameters, and quality test results, enabling complete accountability throughout the supply chain. This documentation capability proves essential for automotive applications where material certification and compliance verification may be required for warranty coverage, regulatory compliance, or quality audit purposes.

Customization & Branding Options

Recognizing the diverse requirements of global automotive markets, comprehensive customization capabilities allow adaptation of the Waterproof Heat-Resistant Single-Sided Pressure Sensitive Acrylic Adhesive Sticker Auto Wiring Masking Cloth Fabric Wrap Harness to specific application needs. Color options enable integration with existing wire harness color coding systems, facilitating identification and organization within complex electrical installations. Custom printing capabilities accommodate part numbers, installation instructions, or brand identification directly on the fabric surface.

Dimensional customization addresses varying application requirements through tailored width and length specifications that optimize material utilization while ensuring adequate coverage for specific wire harness configurations. Special formulations can enhance particular performance characteristics such as increased temperature resistance for extreme-duty applications or enhanced flexibility for installations requiring tight bend radii.

Private labeling services support OEM requirements and aftermarket branding strategies, enabling automotive manufacturers and suppliers to incorporate this advanced masking cloth fabric wrap technology under their own product lines. Technical documentation, installation guides, and training materials can be customized to reflect specific brand requirements while maintaining the technical integrity and performance characteristics of the base product.

Packaging & Logistics Support

Efficient packaging solutions protect the integrity of this specialized auto wiring masking material throughout international shipping and storage processes while optimizing logistics costs and handling convenience. Protective packaging prevents contamination of the adhesive surface, maintains fabric quality, and ensures that the material arrives at destination facilities in optimal condition for immediate use. Climate-controlled storage recommendations and shelf-life guidelines provide clear guidance for inventory management and quality preservation.

Flexible packaging configurations accommodate diverse order quantities and application requirements, from small quantities for service operations to large-volume shipments for manufacturing facilities. Standardized packaging dimensions facilitate efficient warehouse operations and shipping optimization while custom packaging options address specific handling or storage constraints at customer facilities.

Global logistics capabilities ensure reliable delivery to automotive markets worldwide, with established distribution networks that understand the time-sensitive nature of automotive production schedules. Documentation support includes material safety data sheets, technical specifications, and compliance certifications required for international shipping and customs clearance processes.

Why Choose Us

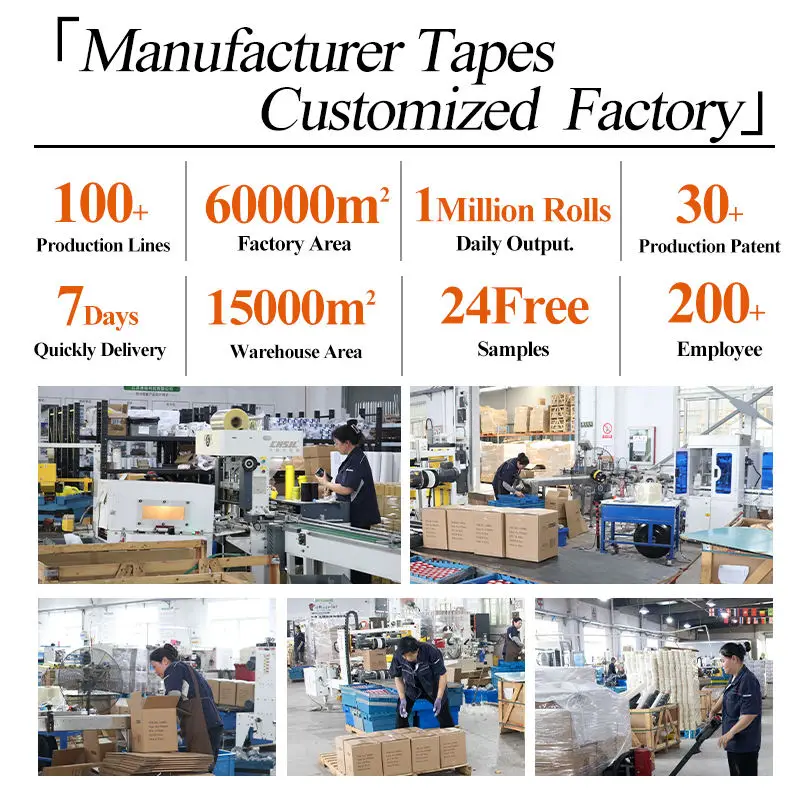

Our commitment to excellence in automotive electrical protection solutions spans over two decades of serving international markets, establishing our reputation as a trusted partner for OEM manufacturers, aftermarket suppliers, and service professionals worldwide. This extensive experience enables deep understanding of automotive industry requirements and the technical challenges faced by electrical system designers and installers across diverse vehicle platforms and operating environments.

Advanced manufacturing capabilities and rigorous quality systems ensure consistent production of this Waterproof Heat-Resistant Single-Sided Pressure Sensitive Acrylic Adhesive Sticker Auto Wiring Masking Cloth Fabric Wrap Harness to the exacting standards demanded by automotive applications. Our multi-industry expertise encompasses collaboration with leading vehicle manufacturers, electrical component suppliers, and aftermarket distributors, providing valuable insights that drive continuous product improvement and innovation.

Technical support services complement our manufacturing excellence through application engineering assistance, installation training programs, and ongoing customer support that ensures optimal results from our fabric wrap harness technology. This comprehensive approach to customer partnership extends beyond product supply to encompass total solution development that addresses specific application challenges and performance requirements unique to each customer's operational environment.

Conclusion

The Waterproof Heat-Resistant Single-Sided Pressure Sensitive Acrylic Adhesive Sticker Auto Wiring Masking Cloth Fabric Wrap Harness represents a significant advancement in automotive electrical protection technology, combining proven materials science with innovative manufacturing techniques to deliver superior performance in demanding applications. Its unique combination of waterproofing capabilities, heat resistance, and pressure-sensitive convenience addresses the critical need for reliable wire harness protection in modern automotive systems. Whether employed in manufacturing operations, service applications, or specialized installations, this advanced masking cloth fabric wrap provides the durability, reliability, and ease of use that automotive professionals require for maintaining electrical system integrity and performance throughout vehicle operational life.

| item | value |

| Adhesive | Acrylic |

| Use | MASKING |

| Place of Origin | China |

| Adhesive Side | Single Sided |

| Material | Cloth |

| Type | Adhesive Sticker |

| Thickness | 0.26mm |

| Adhesive Type | Pressure Sensitive |

| Feature | Heat-resistant |

| Brand Name | YLW |

| Model Number | YLW-- B005 |

| Design Printing | No printing |

| cycle length | 25m |

| paper core | No paper core. |

| Printing Handling | No printing |

| glue | Acrylic |

well

1. who are we?

We are based in Jiangsu, China, start from 2025,sell to Mid East(30.00%),Southeast Asia(20.00%),Central America(20.00%),North America(15.00%),South Asia(15.00%). There are total about - people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

automotive tape

4. why should you buy from us not from other suppliers?

-

5. what services can we provide?

Accepted Delivery Terms: -;

Accepted Payment Currency: -;

Accepted Payment Type: -;

Language Spoken: English