Introduction

Modern automotive manufacturing demands specialized materials that can withstand extreme conditions while maintaining reliable performance throughout the vehicle's operational lifetime. The YLW B006 Heat-Resistant Flame Retardant Automotive Cabin Wiring Sticker Pressure Sensitive Acrylic Cloth Tape Harness Masking represents a breakthrough in automotive-grade adhesive solutions, specifically engineered for the demanding requirements of automotive electrical systems and cabin applications. This professional-grade tape combines advanced acrylic adhesive technology with specialized cloth backing to deliver exceptional heat resistance and flame retardant properties essential for modern vehicle manufacturing and repair operations.

As automotive electrical systems become increasingly complex and operate under more challenging thermal conditions, the need for reliable harness masking and protective solutions has never been greater. This specialized automotive tape addresses critical safety requirements while providing the mechanical strength and adhesive performance that automotive professionals depend on for consistent, long-lasting results in both original equipment manufacturing and aftermarket applications.

Product Overview

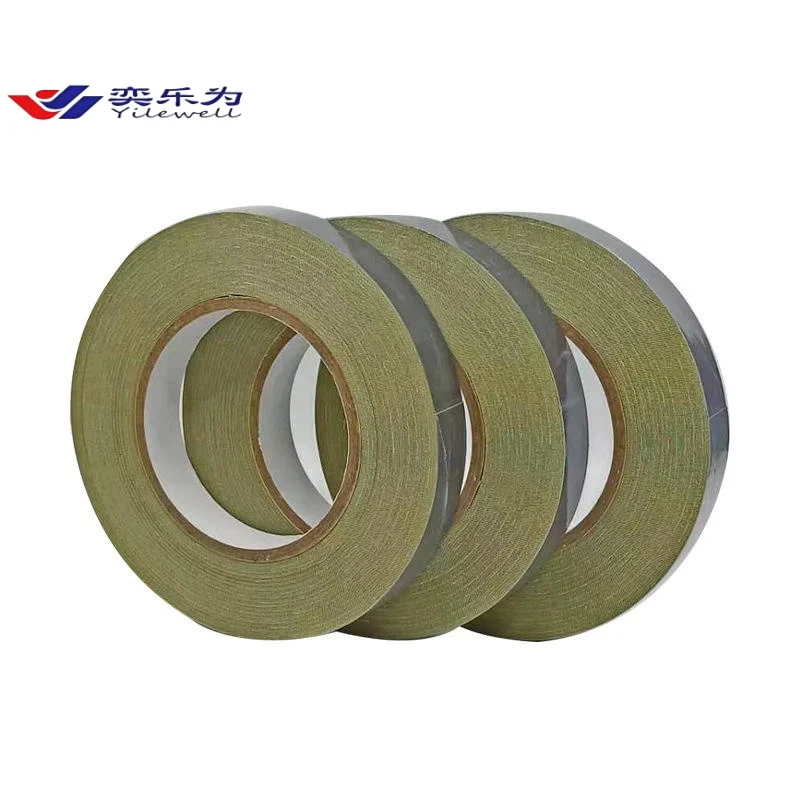

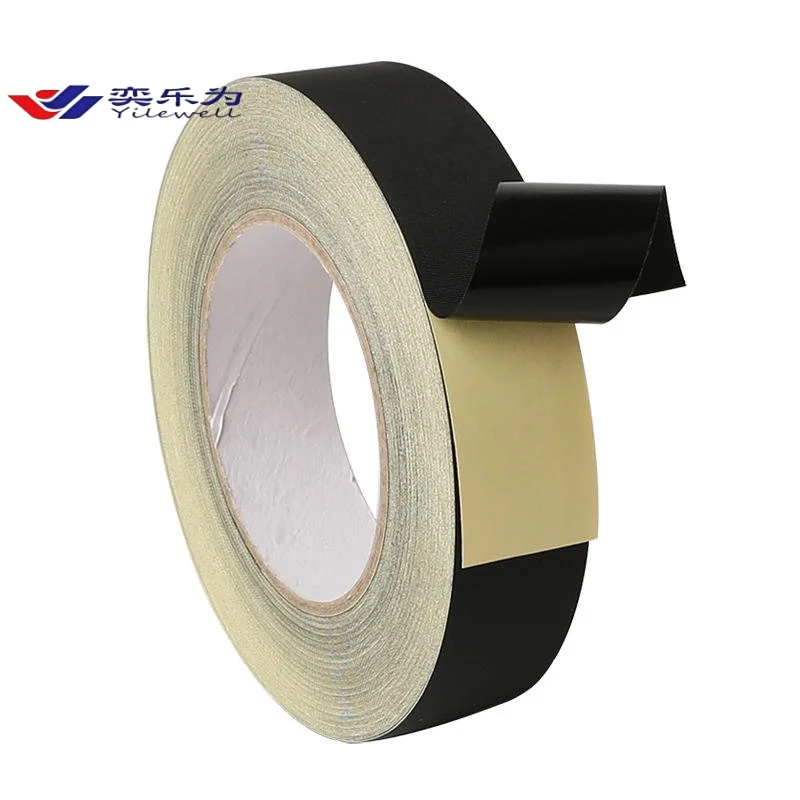

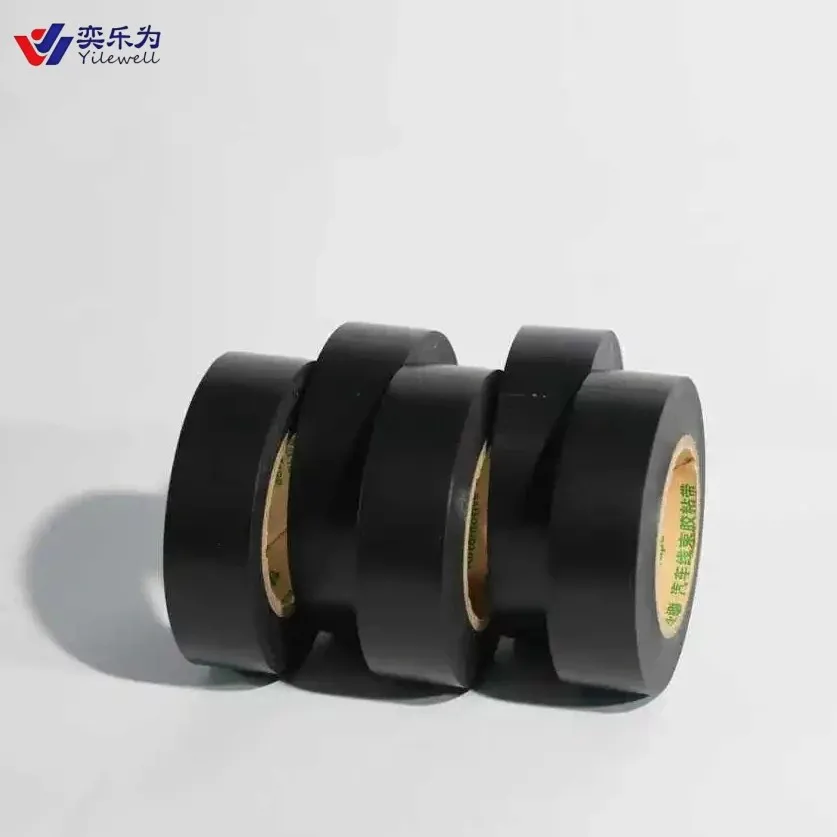

The YLW B006 Heat-Resistant Flame Retardant Automotive Cabin Wiring Sticker represents the convergence of advanced materials science and practical automotive engineering requirements. Built upon a foundation of high-performance acrylic cloth construction, this pressure-sensitive tape delivers exceptional thermal stability and flame resistance characteristics that meet the stringent safety standards required in automotive cabin environments and electrical harness applications.

The unique cloth-backed design provides superior conformability and tear resistance compared to traditional plastic-based automotive tapes, making it ideal for complex routing applications and irregular surface configurations commonly encountered in modern vehicle designs. The pressure-sensitive acrylic adhesive system ensures reliable bonding across a wide range of automotive substrates while maintaining clean removability when required for service or modification operations.

This specialized automotive masking solution incorporates flame retardant additives that provide critical safety protection in high-risk electrical environments, helping to prevent fire propagation and ensuring compliance with automotive safety regulations. The combination of heat resistance and flame retardancy makes this tape particularly valuable for applications near heat sources such as engines, exhaust systems, and high-power electrical components.

Features & Benefits

Advanced Heat Resistance Technology

The YLW B006 Heat-Resistant Flame Retardant Automotive Cabin Wiring Sticker features advanced thermal stability that enables reliable performance in high-temperature automotive environments. The specialized acrylic cloth construction maintains its physical properties and adhesive strength even when exposed to the elevated temperatures commonly found in engine compartments and cabin electrical systems. This thermal resilience ensures consistent protection and masking effectiveness throughout the vehicle's operational temperature range, preventing adhesive failure or backing material degradation that could compromise electrical system integrity.

Superior Flame Retardant Properties

Safety remains paramount in automotive electrical applications, and this specialized tape incorporates advanced flame retardant chemistry that helps prevent fire propagation in electrical fault conditions. The flame retardant properties work synergistically with the heat-resistant characteristics to provide comprehensive protection in high-risk scenarios. This dual protection system helps manufacturers and service technicians meet increasingly stringent automotive safety standards while providing peace of mind in critical applications where electrical faults could pose significant safety risks.

Pressure-Sensitive Acrylic Adhesive System

The sophisticated pressure-sensitive adhesive system provides immediate bonding capability without requiring heat activation or extended cure times. This acrylic-based adhesive chemistry offers excellent adhesion to a wide variety of automotive substrates including metals, plastics, and composite materials commonly used in modern vehicle construction. The adhesive maintains its bonding strength over extended periods while still allowing for clean removal when necessary for service operations or design modifications.

Flexible Cloth Backing Construction

Unlike rigid plastic tapes that may crack or split under stress, the cloth backing of this automotive masking tape provides exceptional flexibility and conformability. This characteristic proves particularly valuable in harness routing applications where the tape must bend around corners, follow complex cable paths, and accommodate the natural movement of electrical harnesses during vehicle operation. The cloth construction also provides superior tear resistance, reducing waste and improving installation efficiency in production environments.

Applications & Use Cases

The versatility of the YLW B006 Heat-Resistant Flame Retardant Automotive Cabin Wiring Sticker makes it suitable for numerous applications throughout the automotive manufacturing and service industries. Primary applications include electrical harness bundling and protection, where the tape's heat resistance and flame retardant properties provide critical safety benefits in high-risk environments. The tape excels in cabin wiring applications where space constraints and aesthetic requirements demand a low-profile solution that maintains reliable performance over extended periods.

Engine compartment applications represent another key use case, where the combination of heat resistance and chemical stability enables reliable performance in harsh operating conditions. The tape's ability to maintain adhesion and physical properties when exposed to automotive fluids, temperature cycling, and vibration makes it ideal for securing and protecting electrical connections near heat sources such as exhaust manifolds, turbochargers, and high-performance engine components.

Automotive repair and modification applications benefit significantly from the tape's clean removal characteristics and reliable adhesion properties. Service technicians can use this specialized tape for temporary masking during electrical system diagnosis, permanent harness protection in aftermarket installations, and cable management in custom electrical modifications. The flame retardant properties provide added safety assurance in modification scenarios where electrical routing may deviate from original equipment specifications.

Manufacturing quality control and testing applications also leverage the tape's specialized properties for component identification, test point masking, and temporary connection protection during assembly and testing procedures. The consistent performance characteristics and reliable adhesion make it suitable for automated application processes while maintaining the flexibility needed for manual installation in complex assemblies.

Quality Control & Compliance

Manufacturing excellence drives every aspect of the YLW B006 Heat-Resistant Flame Retardant Automotive Cabin Wiring Sticker production process, ensuring consistent quality and performance characteristics that meet the demanding requirements of automotive applications. Comprehensive quality control protocols govern raw material selection, adhesive formulation, and backing material specification to maintain strict performance standards across production batches.

The flame retardant properties undergo rigorous testing to ensure compliance with relevant automotive safety standards and industry specifications. These testing protocols verify both the immediate flame resistance characteristics and long-term stability of the flame retardant additives under various environmental conditions. Quality assurance procedures also validate the heat resistance properties through accelerated aging tests that simulate extended exposure to automotive operating temperatures.

Adhesive performance testing encompasses bond strength evaluation across multiple substrate types, temperature cycling resistance, and long-term adhesion stability under automotive environmental conditions. These comprehensive testing protocols ensure reliable performance in real-world applications while maintaining the clean removability characteristics essential for service and modification operations.

Environmental compliance considerations include evaluation of volatile organic compound emissions, recyclability characteristics, and compatibility with automotive manufacturing environmental standards. The manufacturing process incorporates sustainable practices while maintaining the high-performance characteristics required for demanding automotive applications.

Customization & Branding Options

Understanding that automotive manufacturers and suppliers often require specialized solutions tailored to specific applications, comprehensive customization capabilities enable modification of the YLW B006 Heat-Resistant Flame Retardant Automotive Cabin Wiring Sticker to meet unique requirements. Custom width configurations accommodate various harness sizes and application requirements, while specialized adhesive formulations can be developed for specific substrate compatibility or environmental resistance needs.

Private labeling and branding services allow automotive suppliers and distributors to incorporate their corporate identity into the product presentation while maintaining the high-performance characteristics that define this specialized automotive tape. Custom packaging options can include company logos, product identification systems, and specialized documentation to support quality control and traceability requirements in automotive manufacturing environments.

Technical customization extends to specialized backing materials, alternative adhesive chemistries, and modified flame retardant formulations designed to meet specific automotive OEM requirements or unique application challenges. These customization capabilities ensure optimal performance in specialized applications while maintaining compliance with relevant safety and performance standards.

Color coding and identification systems can be incorporated to support manufacturing efficiency and quality control procedures. Custom colors enable easy identification of different tape specifications or application types, reducing installation errors and improving manufacturing process control in high-volume production environments.

Packaging & Logistics Support

Efficient packaging and logistics support ensure that the YLW B006 Heat-Resistant Flame Retardant Automotive Cabin Wiring Sticker reaches customers in optimal condition while minimizing transportation costs and environmental impact. Specialized packaging systems protect the adhesive properties and backing material integrity during storage and transportation, maintaining product performance characteristics until final application.

Flexible packaging configurations accommodate various order quantities and application requirements, from small-quantity samples for testing and evaluation to large-volume production supplies. Packaging designs consider the storage requirements of automotive manufacturing facilities, including space constraints, inventory management needs, and material handling equipment compatibility.

Documentation support includes comprehensive technical data sheets, application guidelines, and safety information designed to support proper product selection and installation procedures. Quality certificates and traceability documentation enable automotive manufacturers to maintain comprehensive quality records required for automotive industry compliance and quality management systems.

International shipping capabilities support global automotive manufacturing operations with appropriate packaging protection for various transportation modes and climate conditions. Specialized packaging materials and protection systems ensure product integrity during extended international shipping while maintaining compliance with international shipping regulations and customs requirements.

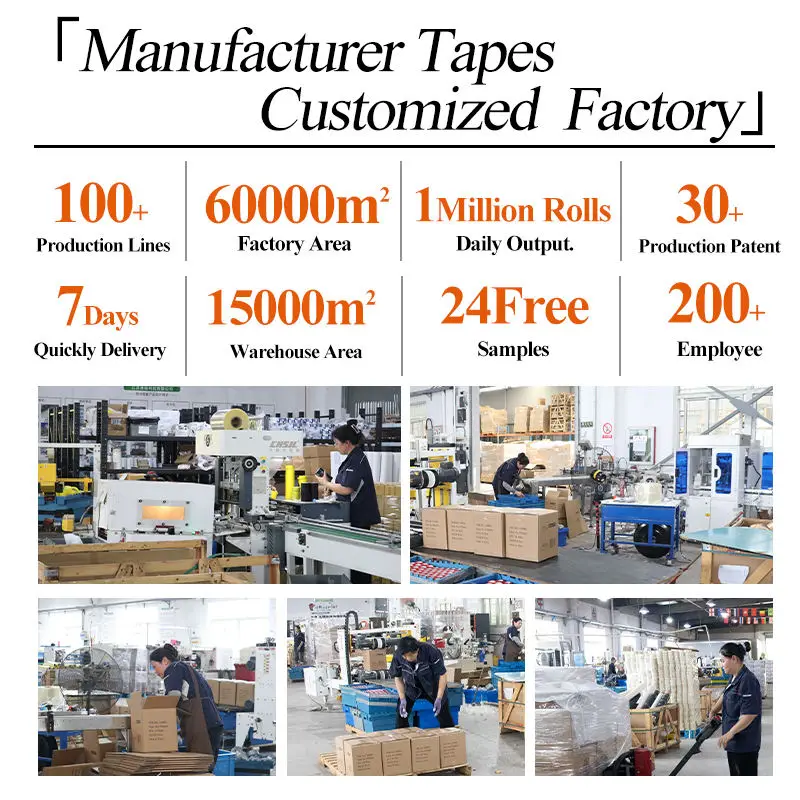

Why Choose Us

With extensive experience serving automotive manufacturers and suppliers across global markets, our commitment to technical excellence and customer satisfaction has established a reputation for delivering reliable, high-performance solutions that meet the evolving needs of the automotive industry. Our comprehensive understanding of automotive manufacturing requirements and regulatory compliance ensures that every product meets the stringent quality and performance standards expected in modern vehicle production.

As a recognized metal packaging manufacturer and custom tin box supplier, our diversified manufacturing capabilities extend beyond automotive adhesive solutions to encompass comprehensive material handling and packaging expertise. This broad industrial experience enables us to understand the complete supply chain requirements of automotive manufacturers while providing integrated solutions that support efficient manufacturing operations.

Our OEM tin packaging solutions and metal packaging supplier services demonstrate the same commitment to quality and technical innovation that drives our automotive adhesive product development. This comprehensive industrial capability ensures consistent quality standards and reliable supply chain support across all product categories, providing customers with confidence in long-term partnership relationships.

Technical support services include application engineering assistance, product selection guidance, and custom solution development to address unique automotive challenges. Our experienced technical team works closely with customers to optimize product selection and application procedures, ensuring maximum performance and cost-effectiveness in demanding automotive environments. Continuous research and development efforts focus on advancing adhesive technology to meet emerging automotive requirements and industry trends.

Conclusion

The YLW B006 Heat-Resistant Flame Retardant Automotive Cabin Wiring Sticker Pressure Sensitive Acrylic Cloth Tape Harness Masking represents a sophisticated solution for the demanding requirements of modern automotive electrical systems. Its unique combination of heat resistance, flame retardant properties, and pressure-sensitive acrylic adhesive technology provides automotive manufacturers and service professionals with a reliable tool for ensuring electrical system safety and performance. The cloth backing construction delivers the flexibility and durability needed for complex routing applications while maintaining clean removability for service operations. Whether supporting original equipment manufacturing, aftermarket modifications, or service applications, this specialized automotive tape provides the performance characteristics and safety features essential for modern vehicle electrical systems.

| item | value |

| Adhesive | Acrylic |

| Use | MASKING |

| Place of Origin | China |

| Adhesive Side | Single Sided |

| Material | Cloth |

| Type | Adhesive Sticker |

| Thickness | 0.26mm |

| Adhesive Type | Pressure Sensitive |

| Feature | Heat-resistant |

| Brand Name | YLW |

| Model Number | YLW-- B005 |

| Design Printing | No printing |

| cycle length | 25m |

| paper core | No paper core. |

| Printing Handling | No printing |

| glue | Acrylic |

well

1. who are we?

We are based in Jiangsu, China, start from 2025,sell to Mid East(30.00%),Southeast Asia(20.00%),Central America(20.00%),North America(15.00%),South Asia(15.00%). There are total about - people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

automotive tape

4. why should you buy from us not from other suppliers?

-

5. what services can we provide?

Accepted Delivery Terms: -;

Accepted Payment Currency: -;

Accepted Payment Type: -;

Language Spoken: English