Introduction

The automotive industry demands exceptional reliability and safety in every component, especially when it comes to electrical systems and wiring protection. Professional-grade wiring harness tape serves as a critical protective barrier that ensures optimal performance under the most challenging conditions. The YLW Factory 51026 51036 Automotive Cabin Wiring Harness Tape 150 Degree Abrasion Resistant 88103 Flame Retardant 150 Acrylic represents a premium solution engineered specifically for automotive applications where durability, heat resistance, and flame retardancy are paramount.

Modern vehicles operate in increasingly demanding environments, with electrical systems subjected to extreme temperatures, mechanical stress, and potential fire hazards. This specialized automotive tape provides comprehensive protection for wiring harnesses within vehicle cabins, ensuring long-term reliability and safety compliance. Its advanced acrylic adhesive technology combined with flame-retardant properties makes it an indispensable component for automotive manufacturers, repair facilities, and aftermarket professionals worldwide.

Product Overview

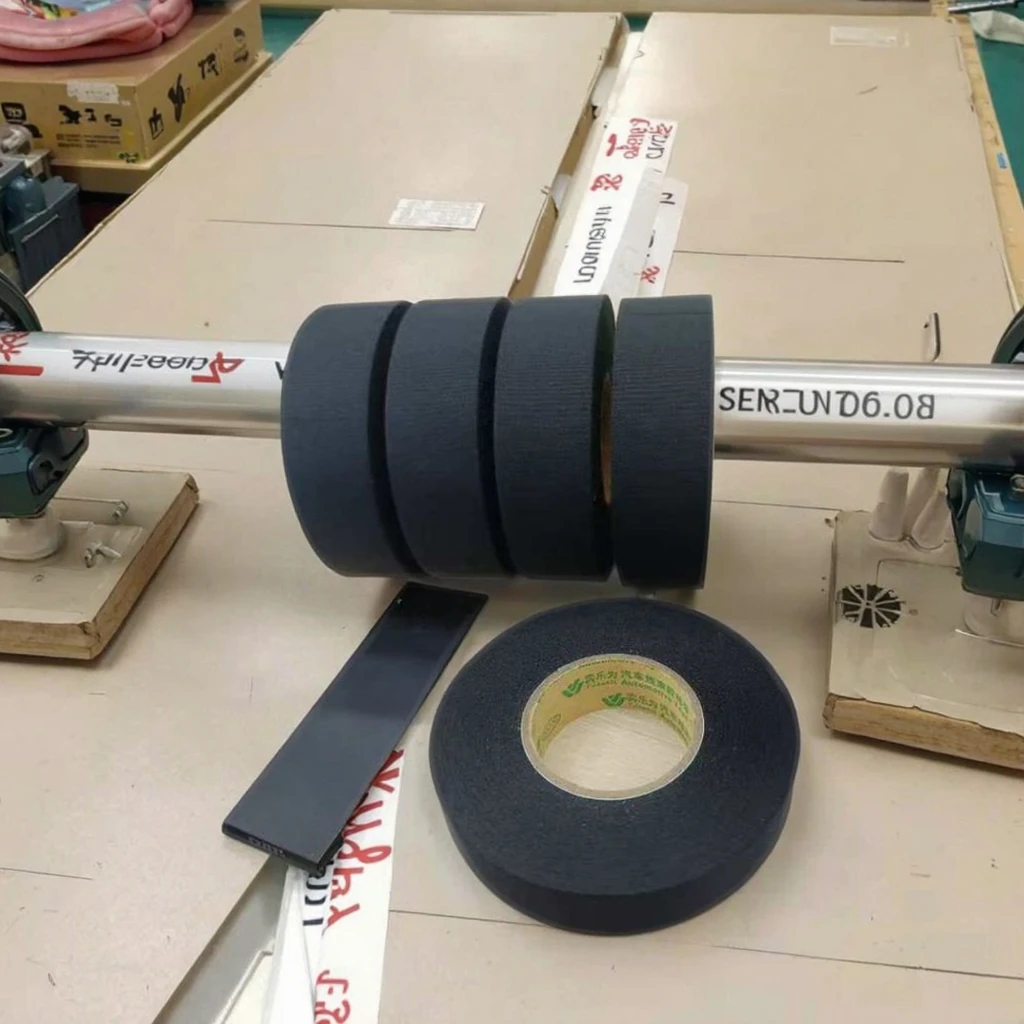

This high-performance automotive wiring harness tape is meticulously engineered to meet the stringent requirements of modern vehicle electrical systems. The tape features an advanced acrylic adhesive system that maintains exceptional bonding strength across a wide temperature range, ensuring reliable performance in both extreme heat and cold conditions. Its flame-retardant properties provide critical safety protection, helping to prevent the spread of electrical fires within vehicle cabins.

The robust construction incorporates specialized materials designed to withstand the harsh operating conditions typical in automotive environments. The tape's abrasion-resistant surface protects against mechanical wear from vibration, movement, and contact with other components. This comprehensive protection system helps extend the service life of electrical wiring systems while maintaining optimal electrical performance and safety standards.

Professional automotive technicians and manufacturers rely on this tape for its consistent performance characteristics and ease of application. The tape conforms well to irregular surfaces and maintains its protective properties even when subjected to the thermal cycling and mechanical stress common in automotive applications. Its specialized formulation ensures compatibility with various wire insulation materials and automotive substrates.

Features & Benefits

Superior Temperature Resistance

The exceptional thermal performance of this automotive wiring harness tape makes it ideal for applications in engine compartments, dashboard areas, and other high-temperature zones within vehicles. The advanced material composition maintains its protective properties and adhesive strength even when exposed to sustained elevated temperatures, ensuring reliable long-term performance in demanding automotive environments.

Enhanced Flame Retardancy

Safety remains paramount in automotive electrical applications, and this tape's flame-retardant properties provide crucial protection against fire hazards. The specialized flame-retardant formulation helps prevent the ignition and spread of fires, contributing to overall vehicle safety and compliance with automotive safety standards. This feature is particularly important in cabin applications where passenger safety is the primary concern.

Outstanding Abrasion Protection

The tape's robust surface construction provides excellent resistance to mechanical wear and abrasion, protecting underlying wiring from damage caused by vibration, movement, and contact with other vehicle components. This abrasion resistance helps prevent wire insulation damage that could lead to electrical faults, short circuits, or system failures, thereby enhancing overall system reliability and reducing maintenance requirements.

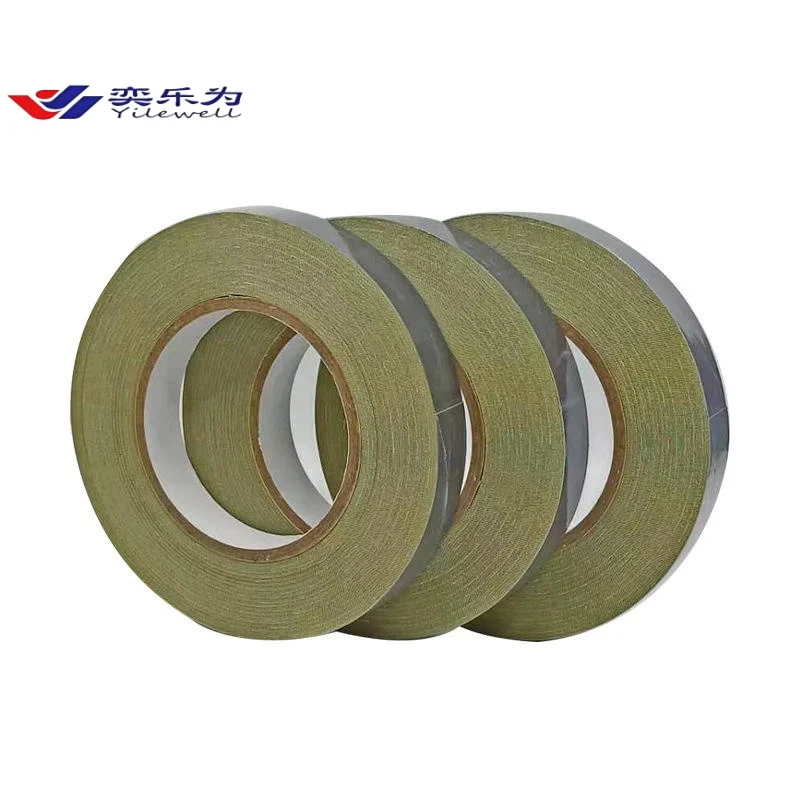

Advanced Acrylic Adhesive Technology

The specialized acrylic adhesive system delivers superior bonding performance across a wide range of temperatures and environmental conditions. This advanced adhesive technology ensures secure attachment to various automotive substrates while maintaining flexibility and conformability. The adhesive resists degradation from temperature cycling, humidity, and exposure to automotive fluids, providing long-lasting protection.

Applications & Use Cases

Automotive manufacturers and repair facilities utilize this premium wiring harness tape across numerous applications within vehicle electrical systems. Dashboard wiring assemblies benefit significantly from the tape's heat resistance and flame-retardant properties, as these areas often experience elevated temperatures from sun exposure and electronic component heat generation. The tape's conformability allows it to wrap securely around complex wiring bundles and follow irregular routing paths typical in modern vehicle designs.

Engine compartment applications represent another critical use case where this tape's temperature resistance proves invaluable. Wiring harnesses near heat sources such as exhaust manifolds, turbochargers, and engine blocks require exceptional thermal protection to maintain electrical integrity. The tape's ability to withstand sustained high temperatures while maintaining its protective properties makes it ideal for these demanding applications.

Door panel and interior trim wiring installations also benefit from this tape's comprehensive protection capabilities. These applications often involve repeated flexing and movement as doors open and close, making the tape's abrasion resistance and flexible adhesive system essential for long-term reliability. The flame-retardant properties provide additional safety assurance in passenger compartment applications where fire prevention is critical.

Aftermarket automotive professionals frequently specify this tape for repair and modification applications where OEM-level protection is required. Custom audio installations, lighting modifications, and electrical system repairs all benefit from the tape's professional-grade protection characteristics. Its ease of application and reliable performance make it suitable for both production line and field repair environments.

Quality Control & Compliance

Rigorous quality control processes ensure that every roll of this automotive wiring harness tape meets the exacting standards required for automotive applications. Comprehensive testing protocols evaluate thermal performance, flame retardancy, adhesive strength, and abrasion resistance under conditions that simulate real-world automotive environments. These quality assurance measures help ensure consistent performance and reliability across all production batches.

The manufacturing process incorporates advanced quality monitoring systems that track critical parameters throughout production. Material purity, adhesive formulation, and physical properties are continuously monitored to maintain specification compliance. This systematic approach to quality control helps ensure that the tape performs reliably in demanding automotive applications where failure is not an option.

Industry compliance standards guide the development and production of this automotive tape, ensuring compatibility with automotive OEM requirements and aftermarket professional standards. The tape's formulation and performance characteristics align with recognized automotive industry specifications for wiring protection materials. This compliance focus provides confidence for automotive professionals specifying materials for critical electrical protection applications.

Customization & Branding Options

Understanding that different automotive applications may require specific performance characteristics or physical properties, customization options are available to meet unique project requirements. Width variations, adhesive formulations, and backing material modifications can be developed to address specific application needs while maintaining the core performance benefits of flame retardancy, temperature resistance, and abrasion protection.

Private labeling and branding services enable automotive parts distributors and repair facilities to offer this premium wiring harness tape under their own brand identity. Custom packaging options, including specialized dispensers and application tools, can be developed to enhance the professional presentation and ease of use in specific market segments. These customization capabilities support brand differentiation in competitive automotive aftermarket environments.

Technical consultation services help automotive professionals select the optimal tape configuration for their specific applications. This collaborative approach ensures that the chosen solution provides maximum protection and reliability while meeting cost and performance objectives. Custom specifications can address unique environmental conditions, substrate compatibility requirements, or special application techniques.

Packaging & Logistics Support

Professional packaging solutions protect the integrity of this automotive wiring harness tape throughout storage and transportation. Moisture-resistant packaging prevents adhesive degradation and maintains optimal performance characteristics until the tape is ready for use. Proper packaging also facilitates efficient inventory management and reduces waste in professional automotive service environments.

Flexible packaging configurations accommodate different usage patterns and inventory requirements. Small quantities for specialty repair applications and larger volumes for production line use are both available through appropriate packaging solutions. This flexibility helps automotive professionals maintain optimal inventory levels while ensuring fresh product availability when needed.

Global logistics capabilities ensure reliable product availability for international automotive markets. Established distribution networks and shipping partnerships facilitate timely delivery to automotive manufacturers, distributors, and service facilities worldwide. This comprehensive logistics support helps maintain consistent product availability and supports just-in-time inventory management practices common in the automotive industry.

Why Choose Us

With extensive experience serving the global automotive industry, our company has established a reputation for delivering premium wiring protection solutions that meet the most demanding performance requirements. Our collaborative relationships span multiple continents and encompass partnerships with leading automotive manufacturers, parts distributors, and professional service organizations. This international presence provides deep understanding of regional requirements and quality expectations across diverse automotive markets.

Our multi-industry expertise extends beyond automotive applications to encompass aerospace, marine, and industrial sectors where similar performance requirements exist. This broad experience base contributes to continuous innovation and improvement in our automotive tape products. The cross-pollination of technologies and techniques from different industries helps ensure that our automotive solutions incorporate the latest advances in materials science and manufacturing processes.

As a recognized specialty packaging manufacturer, we understand the critical importance of reliable protection systems in demanding applications. Our commitment to quality and innovation has earned recognition from automotive professionals worldwide who depend on our products for critical electrical protection applications. This reputation for excellence reflects our dedication to meeting and exceeding customer expectations through superior product performance and comprehensive support services.

Conclusion

The YLW Factory 51026 51036 Automotive Cabin Wiring Harness Tape 150 Degree Abrasion Resistant 88103 Flame Retardant 150 Acrylic represents a comprehensive solution for automotive electrical protection applications where reliability, safety, and performance cannot be compromised. Its combination of exceptional temperature resistance, flame retardancy, and abrasion protection makes it an essential component for modern vehicle electrical systems. The advanced acrylic adhesive technology ensures long-lasting protection while maintaining the flexibility and conformability required for complex automotive wiring installations. Whether used in production line applications or professional repair environments, this premium automotive tape delivers the consistent performance and reliability that automotive professionals demand for critical electrical protection applications.

| item | value |

| Adhesive | Acrylic |

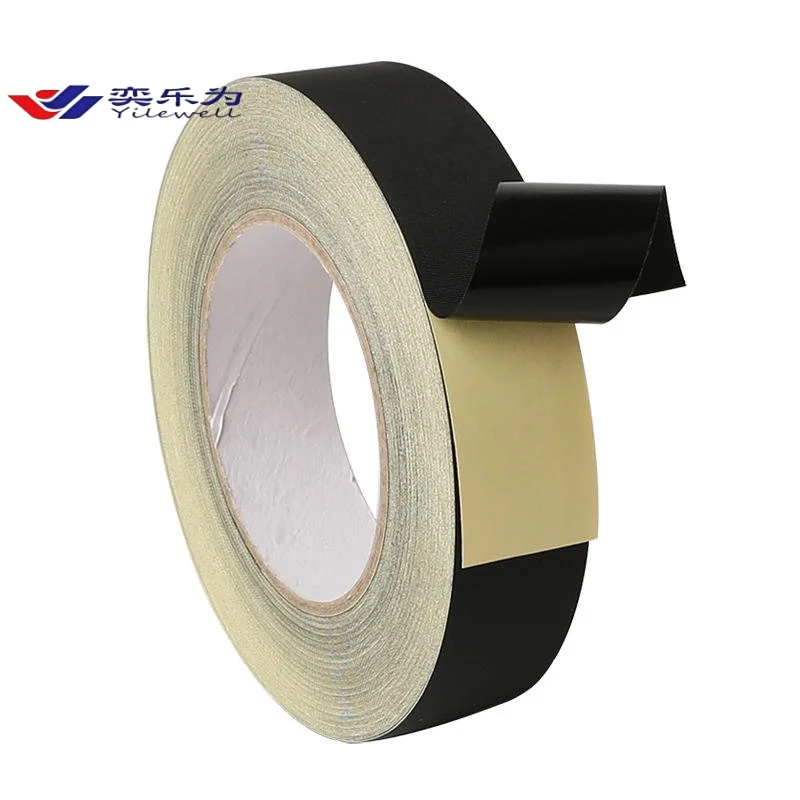

| Use | MASKING |

| Place of Origin | China |

| Adhesive Side | Single Sided |

| Material | Cloth |

| Type | Adhesive Sticker |

| Thickness | 0.26mm |

| Adhesive Type | Pressure Sensitive |

| Feature | Heat-resistant |

| Brand Name | YLW |

| Model Number | YLW-- B005 |

| Design Printing | No printing |

| cycle length | 25m |

| paper core | No paper core. |

| Printing Handling | No printing |

| glue | Acrylic |

well

1. who are we?

We are based in Jiangsu, China, start from 2025,sell to Mid East(30.00%),Southeast Asia(20.00%),Central America(20.00%),North America(15.00%),South Asia(15.00%). There are total about - people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

automotive tape

4. why should you buy from us not from other suppliers?

-

5. what services can we provide?

Accepted Delivery Terms: -;

Accepted Payment Currency: -;

Accepted Payment Type: -;

Language Spoken: English