Introduction

The automotive and industrial sectors demand exceptional materials that can withstand extreme thermal conditions while maintaining structural integrity and performance. The YLW Fiber Insulation Tape High Temperature Resistant Heat-resistant Masking Single Sided Automotive Wiring Harness Cloth Tape represents a breakthrough in thermal protection technology, specifically engineered for applications where conventional materials fail. This specialized insulation solution combines advanced fiber technology with precision manufacturing to deliver superior heat resistance, durability, and reliability across diverse industrial applications.

Modern manufacturing processes increasingly require materials that can perform under challenging conditions, particularly in automotive wiring harness protection, industrial equipment insulation, and high-temperature masking applications. This innovative cloth tape addresses these critical requirements by providing a single-sided adhesive solution that maintains its protective properties even when exposed to extreme thermal stress. The product's unique fiber construction ensures consistent performance while offering the flexibility and ease of application that busy production environments demand.

Product Overview

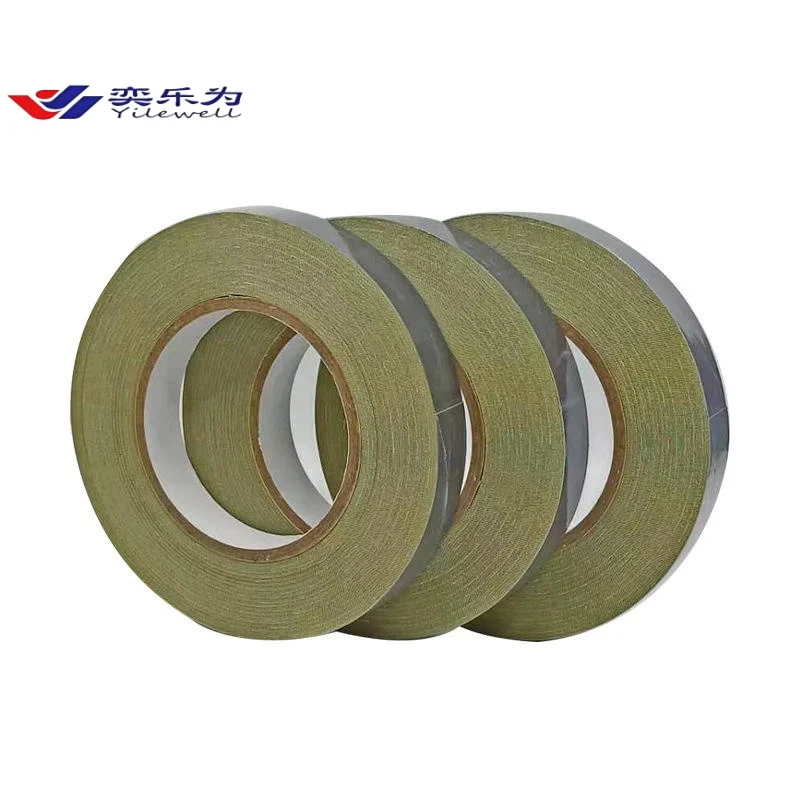

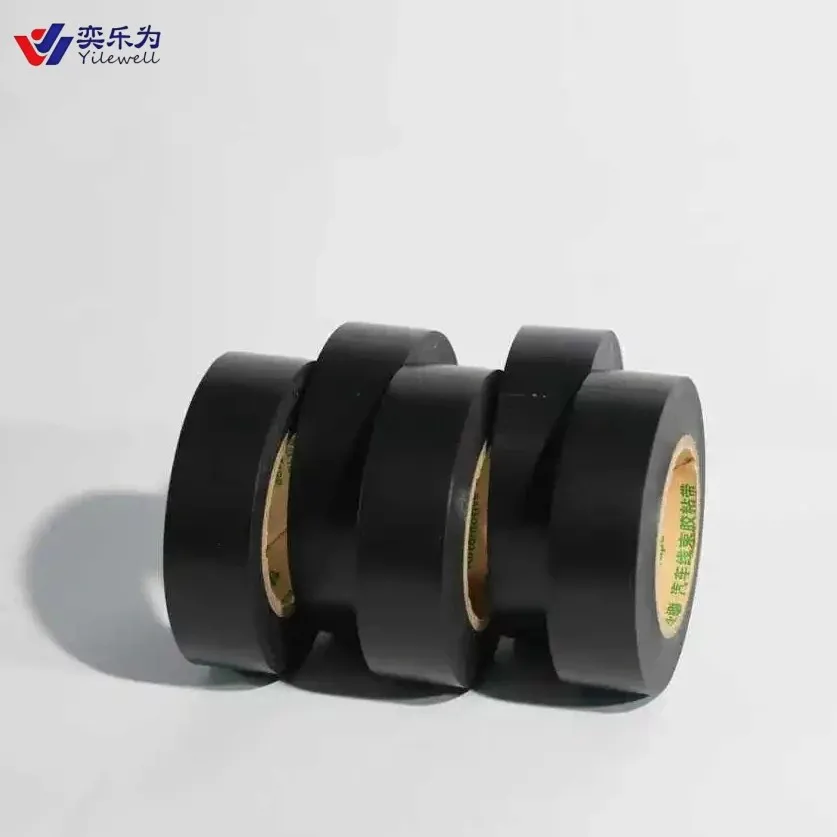

The YLW Fiber Insulation Tape High Temperature Resistant Heat-resistant Masking Single Sided Automotive Wiring Harness Cloth Tape features a sophisticated construction that combines high-performance fibers with a specially formulated adhesive system. The cloth-based substrate provides exceptional tensile strength and conformability, making it ideal for wrapping complex geometries and irregular surfaces commonly found in automotive wiring harness applications. The single-sided adhesive configuration allows for precise application control while ensuring secure bonding to various substrate materials.

This thermal insulation tape exhibits remarkable resistance to temperature fluctuations, maintaining its protective characteristics across a wide operational range. The fiber composition has been carefully selected to provide optimal balance between flexibility and thermal barrier properties, ensuring that protected components remain within safe operating parameters. The tape's construction incorporates advanced materials science principles to deliver consistent performance in demanding industrial environments where failure is not an option.

The cloth substrate design offers superior handling characteristics compared to traditional film-based alternatives, providing installers with better grip and control during application processes. This enhanced workability translates to improved installation efficiency and reduced material waste, making it an economically attractive choice for high-volume production environments. The tape's dimensional stability ensures that it maintains its protective coverage even under mechanical stress and thermal cycling conditions.

Features & Benefits

Advanced Thermal Protection

The exceptional heat resistance capabilities of this specialized tape stem from its carefully engineered fiber matrix, which creates an effective thermal barrier between heat sources and sensitive components. The material's thermal properties remain stable across extended temperature ranges, providing consistent protection that doesn't degrade over time or with repeated thermal cycling. This stability is crucial for automotive applications where engine compartment temperatures can vary dramatically during operation.

The tape's thermal insulation properties extend beyond simple heat blocking, as the fiber construction also provides excellent thermal shock resistance. This means that rapid temperature changes, which are common in automotive and industrial environments, do not compromise the tape's protective capabilities or adhesive performance. The material maintains its flexibility and adhesion strength even after prolonged exposure to challenging thermal conditions.

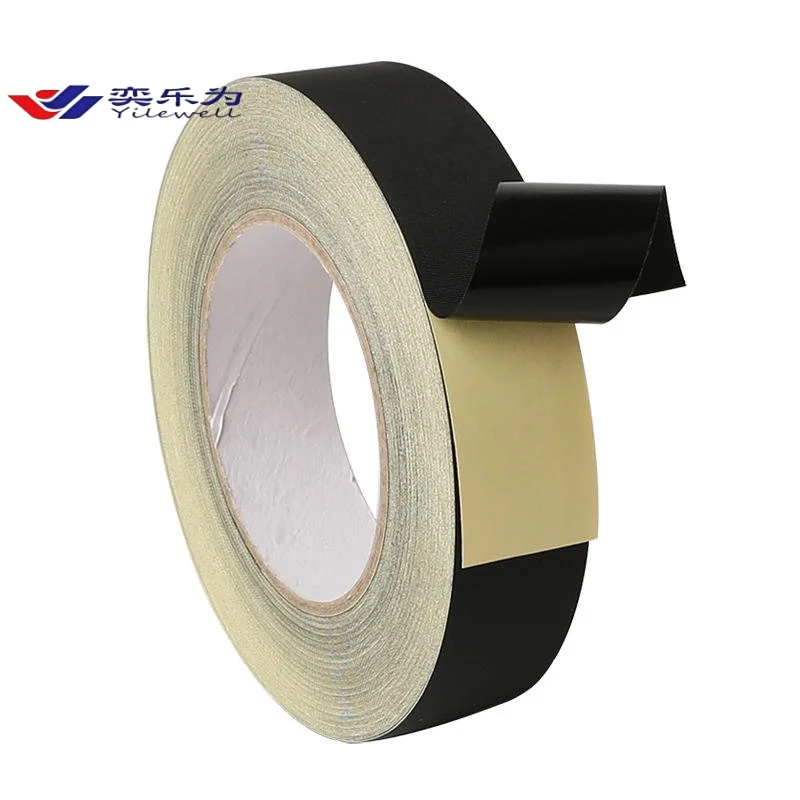

Superior Adhesive Performance

The single-sided adhesive system has been specifically formulated to provide reliable bonding while allowing for clean removal when necessary. This balance is particularly important in masking applications where temporary protection is required, and in maintenance situations where access to protected components may be needed. The adhesive maintains its holding power under thermal stress while avoiding the aggressive bonding that can damage delicate surfaces during removal.

The adhesive's performance characteristics include excellent resistance to automotive fluids, oils, and other chemicals commonly encountered in industrial environments. This chemical resistance ensures that the tape maintains its protective seal and adhesive strength even when exposed to contamination that might compromise lesser materials. The formulation also resists UV degradation, making it suitable for applications with potential sunlight exposure.

Mechanical Durability

The cloth substrate construction provides exceptional tear resistance and conformability, allowing the tape to follow complex contours without compromising its protective integrity. This mechanical performance is essential in automotive wiring harness applications where the tape must accommodate movement, vibration, and mechanical stress without failing. The fiber reinforcement prevents the catastrophic failure modes that can occur with unreinforced materials under stress.

Applications & Use Cases

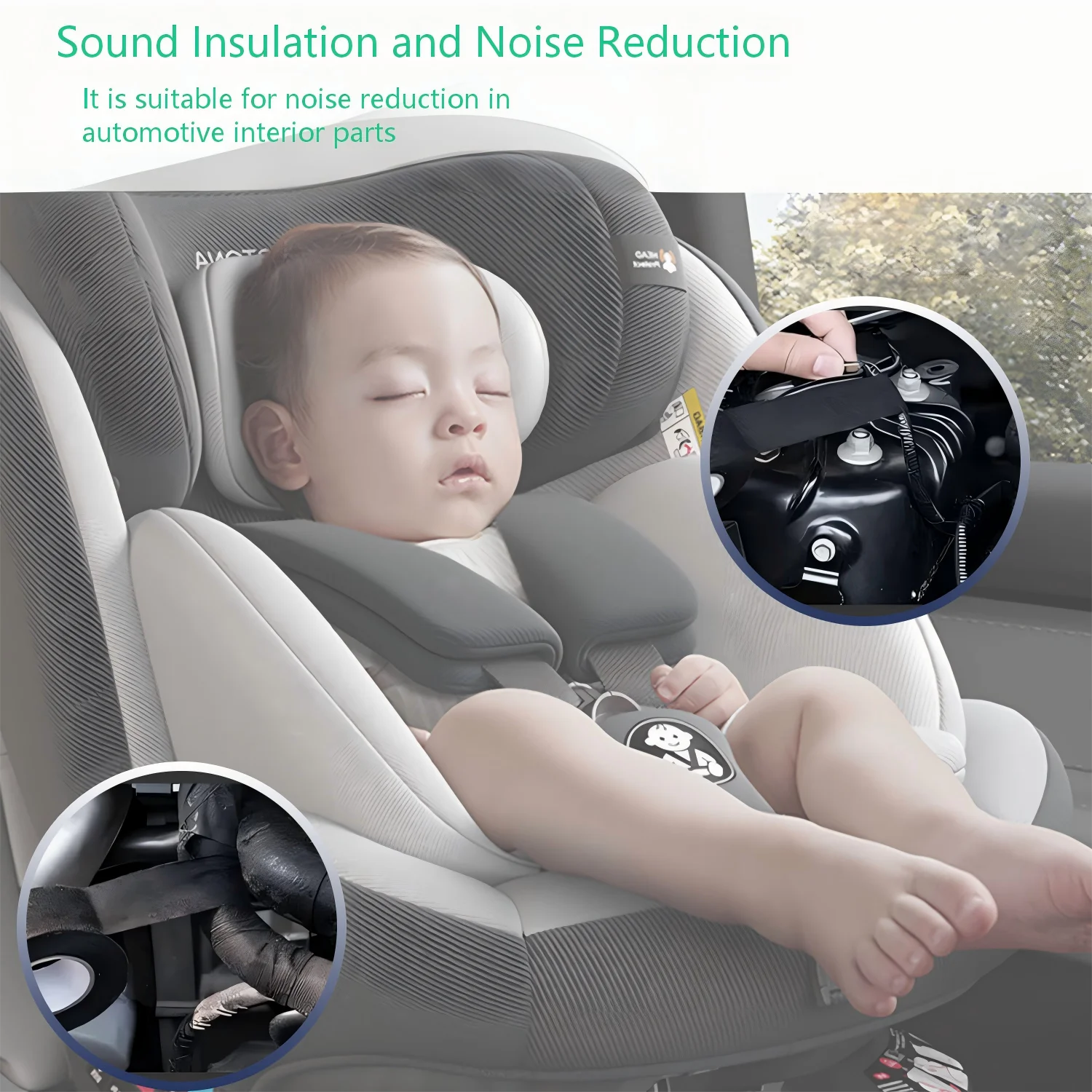

Automotive wiring harness protection represents one of the primary applications for this high-temperature resistant tape. Modern vehicles contain extensive electrical systems that must operate reliably in the challenging environment of the engine compartment, where temperatures, vibration, and chemical exposure create demanding conditions. The YLW Fiber Insulation Tape provides essential thermal and mechanical protection for wire bundles, ensuring that electrical systems maintain their integrity throughout the vehicle's operational life.

Industrial equipment manufacturing benefits significantly from this tape's protective capabilities, particularly in applications involving heating elements, exhaust systems, and high-temperature processing equipment. The tape serves as both thermal insulation and mechanical protection, safeguarding sensitive components from heat damage while providing a barrier against physical wear. Manufacturing processes that involve welding, heat treatment, or high-temperature curing operations rely on this type of specialized protection to maintain quality and prevent equipment damage.

Masking applications in high-temperature environments represent another critical use case, where the tape's heat resistance allows for protective coverage during processes such as powder coating, paint curing, and thermal processing. The single-sided adhesive configuration provides the temporary bonding necessary for masking while ensuring clean removal after processing is complete. This capability is particularly valuable in aerospace, automotive, and industrial equipment manufacturing where surface finish quality is paramount.

Electronic equipment cooling and thermal management applications leverage the tape's insulation properties to create thermal barriers and direct heat flow away from temperature-sensitive components. The material's electrical insulation properties complement its thermal characteristics, making it suitable for applications where both thermal and electrical isolation are required. This dual functionality is especially valuable in power electronics and automotive control systems where heat generation and electrical safety are concurrent concerns.

Quality Control & Compliance

Manufacturing excellence begins with rigorous quality control protocols that ensure every roll of tape meets demanding performance standards. The production process incorporates multiple inspection points where thermal performance, adhesive strength, and dimensional accuracy are verified against established specifications. These quality measures ensure that customers receive consistent performance characteristics across all product batches, regardless of production timing or facility location.

Material compliance with industry standards represents a fundamental aspect of product reliability, particularly for automotive and aerospace applications where regulatory requirements are stringent. The tape's construction materials and manufacturing processes are designed to meet relevant international standards for thermal performance, chemical resistance, and mechanical properties. This compliance foundation provides customers with confidence that the product will perform as expected in critical applications.

Environmental compliance considerations include the selection of materials and manufacturing processes that minimize environmental impact while maintaining performance standards. The product design emphasizes durability and longevity, reducing the frequency of replacement and associated waste generation. Additionally, the manufacturing process incorporates sustainable practices that align with modern environmental stewardship expectations without compromising product quality or performance.

Traceability systems ensure that every aspect of the production process can be documented and verified, providing customers with detailed information about material sources, manufacturing conditions, and quality test results. This comprehensive documentation supports customer quality programs and regulatory compliance requirements, particularly important for customers operating in highly regulated industries such as automotive and aerospace manufacturing.

Customization & Branding Options

Customization capabilities extend beyond standard product offerings to include specialized formulations tailored to specific application requirements. These modifications might involve adjusting thermal performance characteristics, adhesive properties, or dimensional specifications to optimize performance for particular use cases. The manufacturing flexibility allows for custom solutions that address unique customer challenges while maintaining the core performance attributes that define the product category.

Private labeling and branding services provide customers with the opportunity to market the product under their own brand identity, supporting their market positioning and customer relationships. This service includes custom packaging design, product marking, and documentation preparation that aligns with customer branding requirements. The flexibility in branding options makes the product suitable for distribution partners and OEM customers who require branded solutions for their market channels.

Technical consultation services support customers in optimizing product selection and application techniques for their specific requirements. This collaborative approach ensures that customers achieve maximum performance and value from their tape selection while minimizing application challenges and potential performance issues. The consultation process draws on extensive application experience and technical expertise to provide practical solutions for complex challenges.

Packaging & Logistics Support

Professional packaging solutions protect the product during transportation and storage while facilitating efficient handling and inventory management. The packaging design considers the material's sensitivity to environmental conditions, providing appropriate barriers against moisture, temperature fluctuations, and physical damage. This protection ensures that customers receive products in optimal condition regardless of shipping distance or storage duration.

Inventory management support includes flexible packaging configurations that accommodate different order quantities and storage capabilities. Whether customers require small quantities for prototyping or large volumes for production, the packaging options can be configured to optimize storage efficiency and minimize handling costs. This flexibility supports customers across the entire spectrum from small manufacturers to large-scale industrial operations.

International shipping expertise ensures that products reach global customers efficiently and in compliance with relevant regulations. The logistics support includes proper documentation, packaging compliance with international standards, and coordination with reliable shipping partners to minimize transit time and reduce the risk of damage. This comprehensive logistics support enables customers worldwide to access high-quality thermal insulation solutions regardless of their geographic location.

Why Choose Us

Our commitment to excellence in thermal insulation solutions spans decades of experience serving diverse industries worldwide, establishing us as a trusted partner for customers requiring reliable high-temperature protection materials. This extensive experience has enabled us to develop deep understanding of application challenges and performance requirements across automotive, industrial, and specialized manufacturing sectors. Our global presence ensures that we can support customers with consistent quality and service regardless of their location or market focus.

As an established manufacturer with comprehensive capabilities, we combine advanced materials science with precision manufacturing to deliver products that exceed industry expectations. Our multi-industry expertise enables us to understand the unique requirements of different sectors while leveraging cross-industry knowledge to drive innovation and performance improvements. This broad perspective ensures that our customers benefit from the latest advances in thermal protection technology while receiving solutions tailored to their specific needs.

The integration of sustainable manufacturing practices with performance excellence demonstrates our commitment to responsible business operations that benefit both customers and the environment. Our investment in advanced manufacturing technologies and quality systems ensures consistent product performance while minimizing environmental impact through efficient resource utilization and waste reduction. This approach aligns with the sustainability goals of our customers while delivering the reliable performance they require for their critical applications.

Conclusion

The YLW Fiber Insulation Tape High Temperature Resistant Heat-resistant Masking Single Sided Automotive Wiring Harness Cloth Tape represents the pinnacle of thermal protection technology, combining advanced materials science with practical application requirements to deliver exceptional performance in demanding environments. Its unique combination of high-temperature resistance, mechanical durability, and application versatility makes it an indispensable solution for automotive, industrial, and specialized manufacturing applications where conventional materials fall short. The product's comprehensive feature set, from superior thermal protection to reliable adhesive performance, ensures that customers receive a solution that not only meets their immediate needs but also provides long-term value through consistent performance and reliability. This exceptional thermal insulation tape stands as a testament to innovative engineering and manufacturing excellence, providing customers worldwide with the confidence that their critical applications are protected by industry-leading technology.

| item | value |

| Adhesive | Acrylic |

| Use | MASKING |

| Place of Origin | China |

| Adhesive Side | Single Sided |

| Material | Flannel |

| Type | Insulation Tape |

| Thickness | 0.3mm |

| Adhesive Type | Pressure Sensitive |

| Feature | Heat-resistant |

| Brand Name | YLW |

| Model Number | YLW-R001 |

| Design Printing | Offer Printing |

| cycle length | 10m |

| paper core | Customizable |

| Printing Handling | Offer printing |

| glue | Acrylic |

well

1. who are we?

We are based in Jiangsu, China, start from 2025,sell to Mid East(30.00%),Southeast Asia(20.00%),Central America(20.00%),North America(15.00%),South Asia(15.00%). There are total about - people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

automotive tape

4. why should you buy from us not from other suppliers?

-

5. what services can we provide?

Accepted Delivery Terms: -;

Accepted Payment Currency: -;

Accepted Payment Type: -;

Language Spoken: English