Introduction

The automotive industry demands exceptional performance from every component, especially when it comes to electrical systems and wiring protection. The YLW YLW-- B005 Heat-Resistant Cloth Tape Automotive Cabin Wiring Harness Masking 150 Degree Flame Retardant harness tape represents a breakthrough in automotive electrical insulation technology, designed to meet the stringent requirements of modern vehicle manufacturing and maintenance applications. This specialized cloth tape provides superior heat resistance and flame retardation properties, making it an essential component for automotive professionals who prioritize safety, reliability, and long-term performance in their electrical installations.

Engineered specifically for automotive cabin environments, this advanced harness tape combines the flexibility of cloth backing with enhanced thermal protection capabilities. The product addresses critical challenges faced by automotive manufacturers, repair facilities, and electrical technicians who work with complex wiring systems in confined spaces where heat buildup and fire safety are paramount concerns. Its unique formulation ensures consistent performance across varying temperature conditions while maintaining the mechanical properties necessary for reliable long-term service.

Product Overview

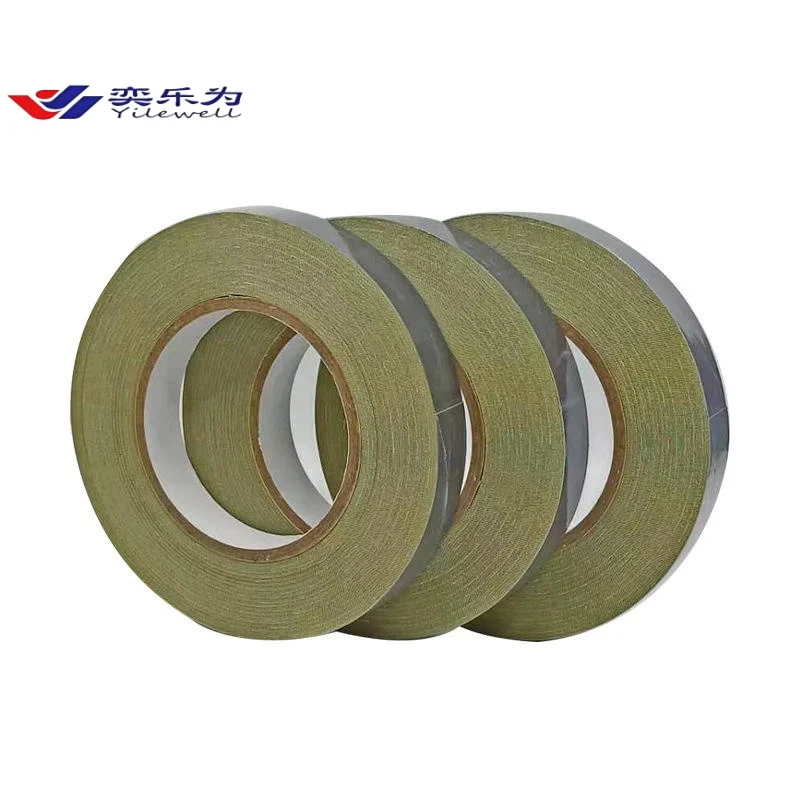

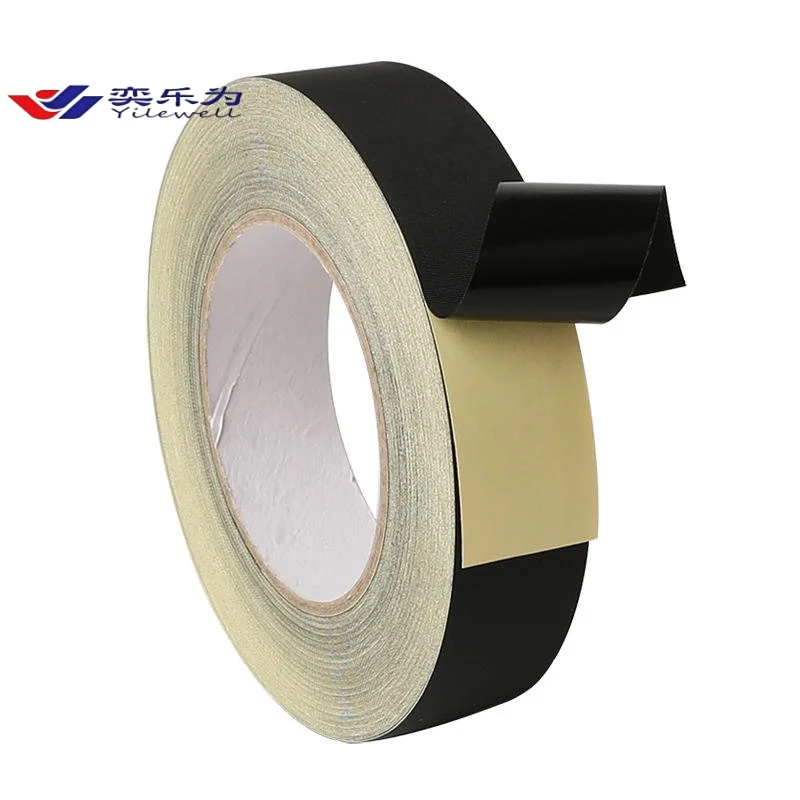

The YLW YLW-- B005 Heat-Resistant Cloth Tape Automotive Cabin Wiring Harness Masking 150 Degree Flame Retardant harness tape features a sophisticated construction that balances thermal protection with practical usability. The cloth backing provides excellent conformability around complex wire bundles and irregular surfaces, while the specialized adhesive system maintains strong bonding even under elevated temperature conditions. This combination makes it particularly suitable for automotive applications where traditional electrical tapes may fail or degrade over time.

The flame retardant properties of this harness tape have been specifically formulated to meet automotive safety standards, providing an additional layer of protection against electrical fires and thermal incidents. The cloth substrate offers superior tear resistance compared to standard vinyl tapes, ensuring that installations remain secure even when subjected to vibration, mechanical stress, and thermal cycling typical of automotive environments. The tape's design philosophy centers on providing maximum protection while remaining easy to apply and remove when necessary for maintenance or repairs.

Features & Benefits

Advanced Heat Resistance Technology

The exceptional heat resistance capabilities of this automotive harness tape stem from its carefully engineered material composition and adhesive chemistry. The cloth backing maintains its structural integrity and flexibility even when exposed to sustained elevated temperatures, preventing the brittleness and cracking that can compromise electrical insulation over time. This thermal stability ensures that wire harnesses remain properly protected throughout the vehicle's operational life, reducing maintenance requirements and enhancing overall system reliability.

Superior Flame Retardant Properties

Fire safety represents a critical concern in automotive electrical systems, where short circuits or component failures can potentially ignite surrounding materials. The flame retardant formulation incorporated into this harness tape provides essential protection by limiting flame spread and reducing heat release during combustion events. This safety feature significantly reduces the risk of electrical fires propagating throughout the vehicle's wiring system, protecting both occupants and valuable electronic components from fire damage.

Enhanced Mechanical Performance

The cloth construction of this specialized tape delivers superior mechanical properties compared to conventional electrical tapes. The fabric backing resists tearing and provides excellent tensile strength, ensuring that harness wrappings remain intact even when subjected to the vibrations and mechanical stresses common in automotive environments. This durability translates to reduced maintenance requirements and improved long-term reliability of electrical installations, making it an ideal choice for both original equipment manufacturers and service professionals.

Applications & Use Cases

Automotive cabin wiring systems present unique challenges that require specialized solutions like the YLW YLW-- B005 Heat-Resistant Cloth Tape Automotive Cabin Wiring Harness Masking 150 Degree Flame Retardant harness tape. Within passenger compartments, wiring harnesses must navigate around heating and air conditioning components, electronic control units, and other heat-generating devices while maintaining electrical integrity and fire safety. This harness tape excels in these demanding applications, providing reliable protection for power distribution systems, lighting circuits, and sensitive electronic interconnections.

Engine bay applications represent another critical use case where this heat-resistant tape demonstrates its value. While not primarily designed for extreme engine compartment temperatures, this product serves effectively in cabin-adjacent areas where moderate heat exposure occurs alongside the need for flame retardation. Transmission tunnel wiring, dashboard electrical systems, and underhood cabin interfaces all benefit from the protective properties offered by this specialized tape solution.

Service and repair applications also benefit significantly from this harness tape's performance characteristics. Automotive technicians frequently need to modify or repair existing wiring installations, and the removability of this cloth tape facilitates maintenance operations while ensuring that temporary or permanent repairs meet safety standards. The tape's conformability allows it to wrap complex harness geometries effectively, making it suitable for both factory installations and field service applications.

Quality Control & Compliance

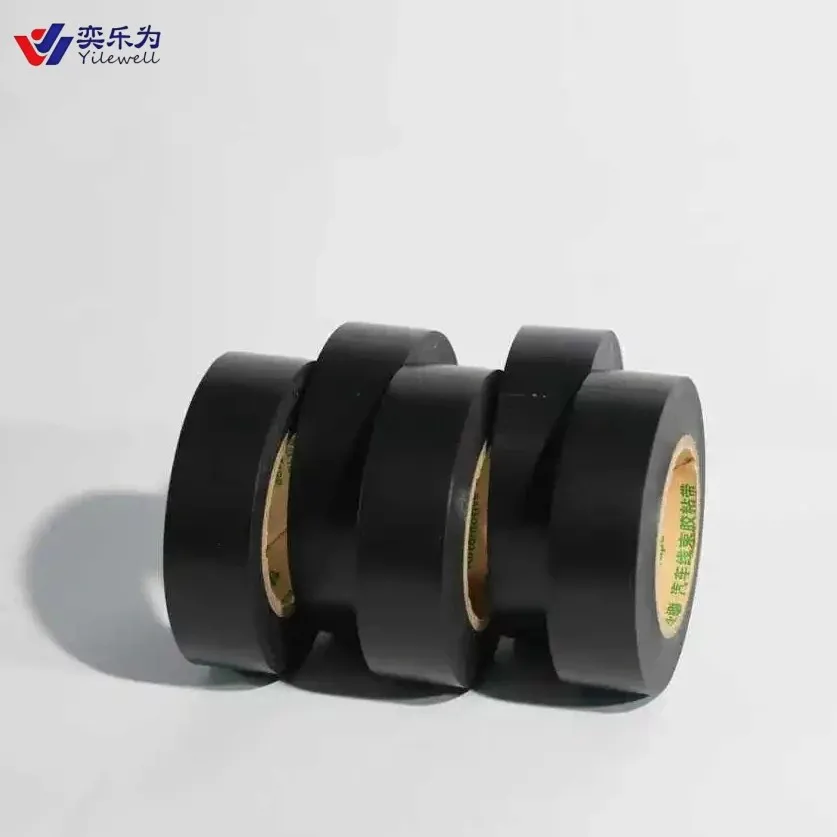

Manufacturing quality represents a fundamental aspect of automotive electrical components, and this heat-resistant harness tape undergoes comprehensive quality control processes to ensure consistent performance characteristics. Each production batch is subjected to rigorous thermal testing to verify heat resistance properties, flame retardation effectiveness, and adhesive performance under various environmental conditions. These quality measures ensure that every roll of tape meets the demanding standards required for automotive applications.

Compliance with international automotive standards forms a cornerstone of this product's development and manufacturing processes. The flame retardant properties meet relevant safety specifications, while the electrical insulation characteristics comply with automotive electrical system requirements. Environmental testing protocols verify performance under temperature cycling, humidity exposure, and mechanical stress conditions typical of automotive service life, ensuring reliable long-term performance in real-world applications.

Material traceability and documentation support automotive industry quality requirements, with comprehensive testing records maintained for each production lot. This documentation enables automotive manufacturers and service providers to maintain proper quality control records and support any warranty or safety investigations that may arise. The manufacturing process incorporates multiple quality checkpoints to identify and eliminate any potential defects before products reach end users.

Customization & Branding Options

The diverse requirements of automotive manufacturers and service providers often necessitate customized solutions that address specific application needs or branding requirements. This heat-resistant harness tape can be manufactured with custom width specifications to match particular wire bundle sizes or installation constraints. Color customization options enable easy identification of different electrical systems or compliance with specific automotive manufacturer color coding standards, enhancing installation efficiency and maintenance procedures.

Private labeling opportunities allow distributors and automotive service chains to offer this high-performance harness tape under their own brand identity while maintaining the proven performance characteristics of the base product. Custom packaging configurations support different distribution models, from bulk industrial supplies to smaller service-oriented packaging suitable for repair facility use. These customization options ensure that the product meets specific market requirements while maintaining the essential performance characteristics that make it suitable for demanding automotive applications.

Technical specification modifications can address unique application requirements while preserving the core heat resistance and flame retardant properties that define this product category. Working closely with automotive engineers and electrical system designers, custom formulations can be developed to address specific temperature ranges, adhesive properties, or mechanical characteristics required for specialized applications within the automotive industry.

Packaging & Logistics Support

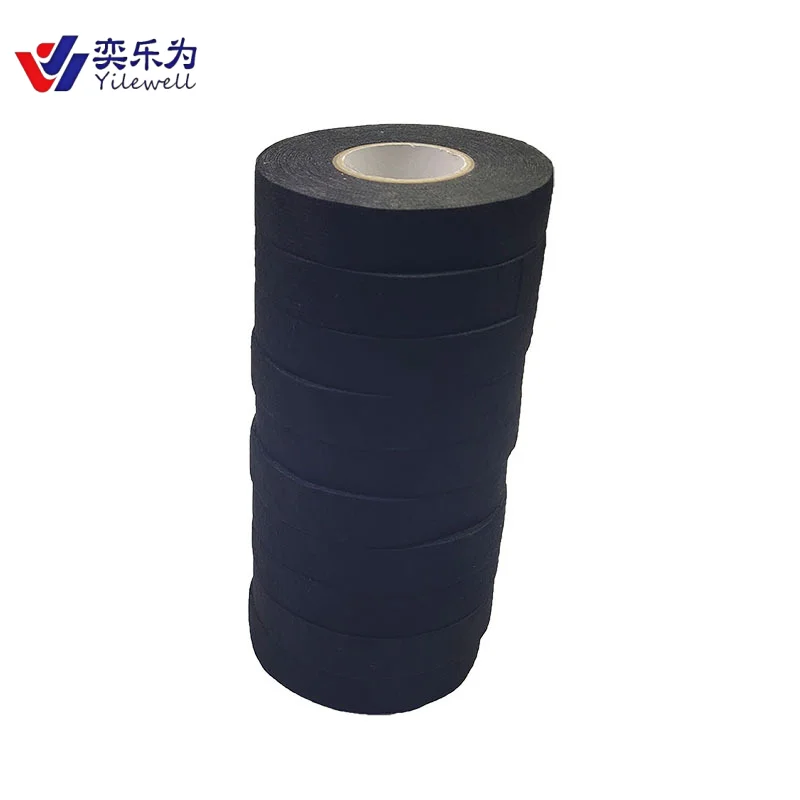

Efficient distribution of automotive electrical components requires packaging solutions that protect product integrity while supporting streamlined logistics operations. The YLW YLW-- B005 Heat-Resistant Cloth Tape Automotive Cabin Wiring Harness Masking 150 Degree Flame Retardant harness tape is available in packaging configurations designed to meet diverse distribution requirements, from bulk industrial shipments to smaller quantities suitable for repair facilities and parts distributors.

Protective packaging prevents contamination and physical damage during shipping and storage, ensuring that the tape's adhesive properties and structural integrity remain intact until application. Individual roll packaging includes clear labeling with product specifications and application guidelines, facilitating proper inventory management and ensuring that technicians select the appropriate materials for their specific applications. Bulk packaging options optimize shipping efficiency for large-volume users while maintaining product protection standards.

International shipping compliance represents an important consideration for global automotive suppliers, and this product's packaging meets relevant transportation regulations for hazardous materials classification, documentation requirements, and handling procedures. Proper documentation supports customs clearance processes and enables efficient distribution through international logistics networks, ensuring that automotive manufacturers and service providers worldwide can access this specialized harness tape solution.

Why Choose Us

With extensive experience serving the global automotive industry, our company has established a reputation for delivering high-performance electrical insulation solutions that meet the demanding requirements of modern vehicle manufacturing and service applications. Our commitment to quality and innovation has earned recognition from automotive manufacturers and service providers across multiple continents, establishing us as a trusted partner for critical electrical system components.

As a specialized metal packaging manufacturer and custom tin packaging solutions provider, we understand the importance of protecting sensitive materials during storage and transportation. This expertise extends to our automotive tape products, where proper packaging and handling ensure that performance characteristics remain intact throughout the distribution chain. Our comprehensive approach to product development, manufacturing, and distribution support enables us to serve as a reliable OEM tin packaging solutions partner for automotive industry clients requiring specialized electrical insulation materials.

Our international market presence and multi-industry expertise provide valuable insights into emerging automotive technologies and evolving safety requirements. This knowledge enables us to anticipate market needs and develop innovative solutions that address future challenges in automotive electrical systems. By maintaining close relationships with automotive engineers, safety specialists, and service professionals worldwide, we ensure that our products continue to meet the highest standards for performance, safety, and reliability in demanding automotive applications.

Conclusion

The YLW YLW-- B005 Heat-Resistant Cloth Tape Automotive Cabin Wiring Harness Masking 150 Degree Flame Retardant harness tape represents a sophisticated solution for automotive electrical system protection, combining advanced materials technology with practical application benefits. Its unique combination of heat resistance, flame retardation, and mechanical durability makes it an essential component for automotive manufacturers, service providers, and electrical technicians who demand reliable protection for critical wiring systems. The product's versatility in both manufacturing and service applications, coupled with comprehensive quality control and customization options, positions it as a premium choice for professionals who prioritize safety, performance, and long-term reliability in their automotive electrical installations.

| item | value |

| Adhesive | Acrylic |

| Use | MASKING |

| Place of Origin | China |

| Adhesive Side | Single Sided |

| Material | Cloth |

| Type | Adhesive Sticker |

| Thickness | 0.26mm |

| Adhesive Type | Pressure Sensitive |

| Feature | Heat-resistant |

| Brand Name | YLW |

| Model Number | YLW-- B005 |

| Design Printing | No printing |

| cycle length | 25m |

| paper core | No paper core. |

| Printing Handling | No printing |

| glue | Acrylic |

well

1. who are we?

We are based in Jiangsu, China, start from 2025,sell to Mid East(30.00%),Southeast Asia(20.00%),Central America(20.00%),North America(15.00%),South Asia(15.00%). There are total about - people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

automotive tape

4. why should you buy from us not from other suppliers?

-

5. what services can we provide?

Accepted Delivery Terms: -;

Accepted Payment Currency: -;

Accepted Payment Type: -;

Language Spoken: English