Introduction

In today's demanding automotive manufacturing environment, precision masking solutions require materials that can withstand extreme conditions while maintaining exceptional performance standards. The Flame Retardant Heat-resistant Flannel Fabric-Single Sided Adhesive 0.3mm Thickness Black for Automotive Masking Use represents a breakthrough in specialized protective materials, engineered specifically for critical automotive applications where traditional masking solutions fall short. This advanced flannel fabric combines superior flame retardancy with exceptional heat resistance, creating an ideal solution for manufacturers who demand reliability, safety, and consistent results in their production processes.

As automotive manufacturing processes become increasingly sophisticated, the need for specialized masking materials has never been greater. This innovative flannel fabric addresses the unique challenges faced by automotive manufacturers, paint shops, and finishing facilities that require dependable protection against high temperatures, chemical exposure, and potential fire hazards. The single-sided adhesive design ensures secure application while facilitating clean removal, making it an indispensable tool for professional automotive masking operations.

Product Overview

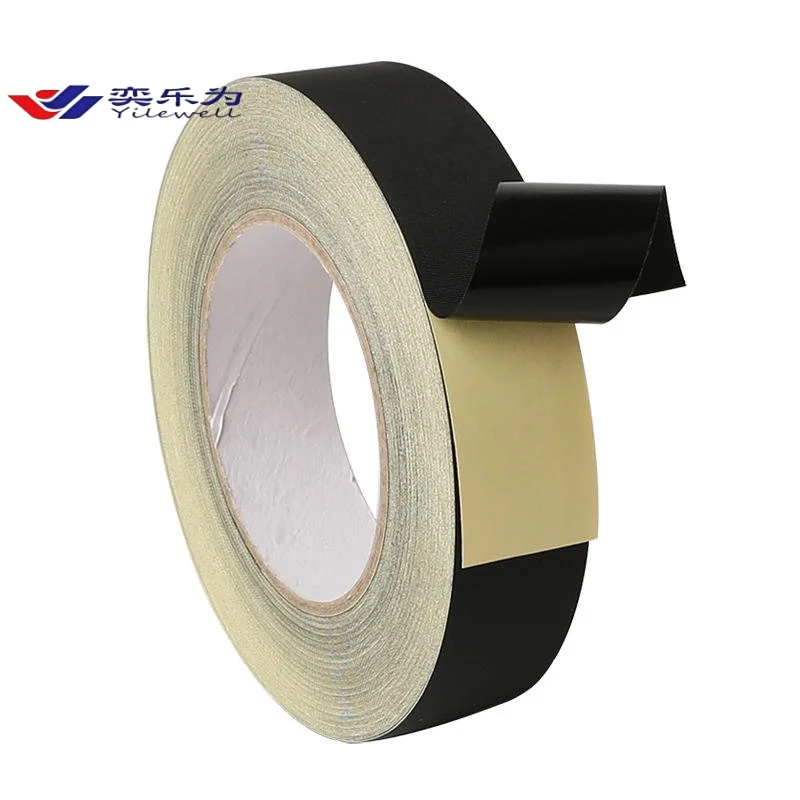

This premium flame retardant flannel fabric stands as a testament to advanced material engineering, specifically designed to meet the rigorous demands of automotive masking applications. The fabric features a unique construction that balances flexibility with durability, allowing it to conform to complex automotive surfaces while maintaining its protective properties under extreme conditions. The black coloration provides excellent contrast visibility during application and inspection processes, enabling operators to achieve precise masking coverage with confidence.

The single-sided adhesive system has been carefully formulated to provide strong initial tack while ensuring clean removal without residue or surface damage. This critical balance makes the material particularly valuable in automotive environments where surface integrity is paramount. The flannel construction offers superior conformability compared to traditional rigid masking materials, allowing it to follow contours and curves that are common in modern automotive design while maintaining consistent adhesion and protection.

Features & Benefits

Advanced Flame Retardant Properties

The flame retardant characteristics of this specialized flannel fabric provide essential safety benefits in automotive manufacturing environments where heat sources and potential ignition risks are present. The material has been engineered to resist ignition and prevent flame propagation, offering critical protection during painting, curing, and heat treatment processes. This flame retardancy does not compromise the fabric's flexibility or adhesive properties, ensuring that safety enhancements do not come at the expense of performance or usability.

Exceptional Heat Resistance Performance

Heat resistance capabilities make this flannel fabric particularly suitable for automotive applications involving elevated temperatures, such as powder coating processes, heat curing operations, and high-temperature paint applications. The material maintains its structural integrity and adhesive bond strength even when exposed to significant thermal stress, preventing adhesive failure or material degradation that could compromise masking effectiveness. This thermal stability ensures consistent performance across varying temperature conditions commonly encountered in automotive manufacturing.

Precision Adhesive Technology

The single-sided adhesive system represents a careful balance of adhesion strength and removability, engineered specifically for automotive masking requirements. The adhesive provides secure bonding to various automotive substrates including metal, plastic, and painted surfaces while maintaining the ability to be removed cleanly without leaving residue or causing surface damage. This precision-engineered adhesive system reduces preparation time and minimizes post-application cleanup, improving overall process efficiency.

Applications & Use Cases

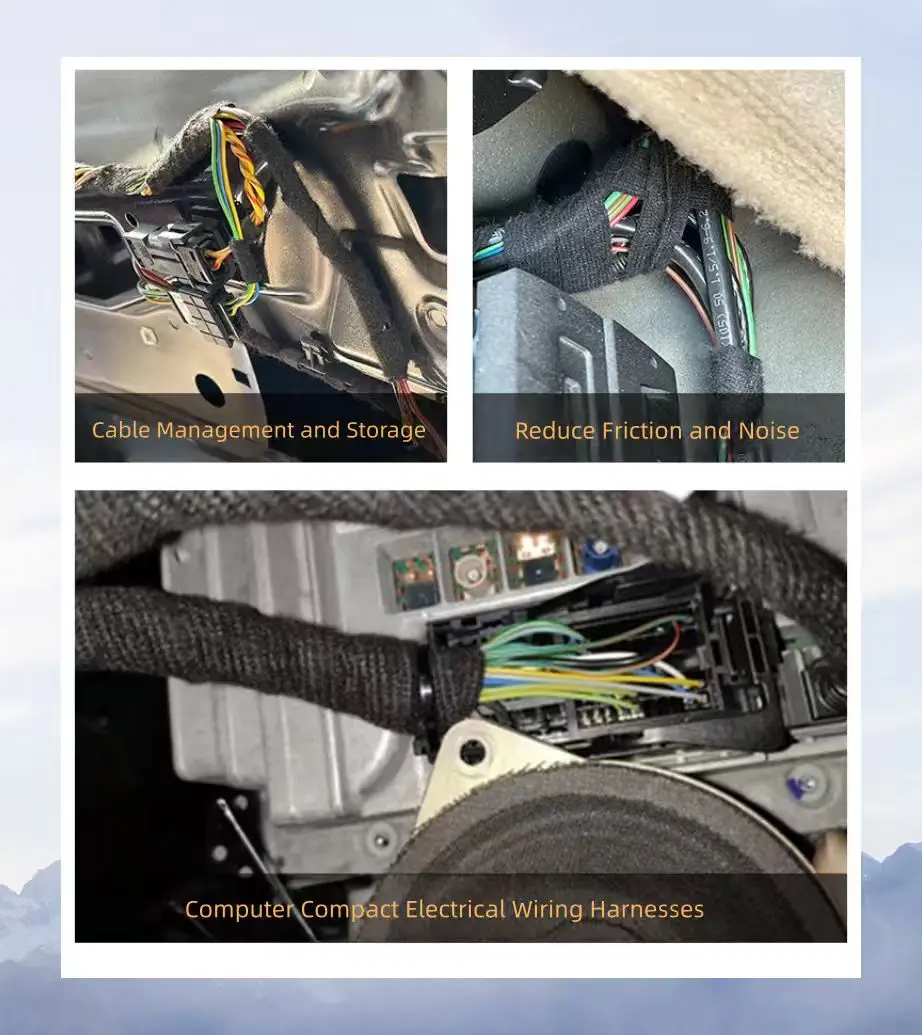

The versatile nature of this Flame Retardant Heat-resistant Flannel Fabric-Single Sided Adhesive 0.3mm Thickness Black for Automotive Masking Use makes it suitable for a wide range of automotive manufacturing and refinishing applications. In automotive paint booths, the material provides reliable protection during spray painting operations, ensuring clean lines and preventing overspray contamination while withstanding the heat generated by industrial drying equipment. The flame retardant properties add an essential safety margin in these environments where paint vapors and heat sources coexist.

Powder coating operations benefit significantly from this material's heat resistance capabilities, as the fabric can withstand the elevated temperatures required for powder curing without degrading or compromising its protective function. The conformable flannel construction allows it to follow complex automotive geometries, making it ideal for masking intricate components such as wheel wells, trim pieces, and decorative elements that require precise protection during finishing processes.

Automotive restoration and custom fabrication shops find this material particularly valuable for projects requiring multiple heat cycles or extended exposure to elevated temperatures. The material's durability allows it to be repositioned if necessary during complex masking operations, providing flexibility for craftsmen who require precision in their work. Additionally, the black coloration helps professional refinishers achieve consistent results by providing clear visual contrast against various automotive surface colors.

Quality Control & Compliance

Manufacturing excellence defines every aspect of this flame retardant flannel fabric's production process, with comprehensive quality control measures ensuring consistent performance across every batch. The material undergoes rigorous testing protocols to verify flame retardant effectiveness, heat resistance performance, and adhesive bond strength under various environmental conditions. These testing procedures simulate real-world automotive manufacturing environments, ensuring that the product will perform reliably when deployed in actual production settings.

Compliance with international safety and performance standards represents a cornerstone of the product development process, with particular attention paid to automotive industry requirements for flame retardancy and material safety. The manufacturing process incorporates advanced quality management systems that track material composition, performance characteristics, and production parameters to ensure consistent product quality. Regular audits and continuous improvement initiatives maintain the high standards that automotive manufacturers demand from their suppliers.

Environmental considerations play an important role in the material's design and manufacturing process, with careful attention paid to sustainable production practices and material composition. The product meets relevant environmental regulations while maintaining the performance characteristics essential for automotive masking applications, demonstrating that environmental responsibility and industrial performance can coexist effectively.

Customization & Branding Options

Understanding that different automotive manufacturing operations have unique requirements, this flame retardant flannel fabric can be adapted to meet specific application needs through various customization options. Width variations allow the material to be optimized for different masking applications, from narrow precision work to broad surface protection, ensuring that manufacturers can select the most efficient configuration for their specific processes. These customization options help optimize material usage and reduce waste in production environments.

Private labeling opportunities enable automotive manufacturers and distributors to incorporate their branding elements while maintaining the superior performance characteristics that define this specialized material. Custom packaging options can include specific handling instructions, application guidelines, and technical specifications tailored to particular automotive applications or customer requirements. This flexibility supports brand consistency while ensuring that end-users receive the technical information necessary for optimal product utilization.

Technical specification modifications can address unique automotive manufacturing requirements, such as specific adhesive formulations for particular substrate types or enhanced flame retardant properties for specialized applications. These customization capabilities ensure that the material can be optimized for specific automotive manufacturing processes while maintaining the core performance characteristics that make it suitable for demanding masking applications.

Packaging & Logistics Support

Professional packaging solutions protect the integrity of this specialized flannel fabric throughout the distribution chain, ensuring that the material reaches end-users in optimal condition. The packaging design considers the material's flame retardant properties and heat resistance characteristics, incorporating protective measures that prevent contamination, moisture exposure, and physical damage during storage and transportation. Clear labeling systems provide essential information about proper handling, storage requirements, and safety considerations.

Logistics coordination addresses the unique requirements of automotive manufacturing schedules, with flexible shipping options that accommodate both regular production needs and urgent project requirements. The packaging configuration optimizes shipping efficiency while protecting product quality, reducing transportation costs and environmental impact. Strategic distribution partnerships ensure reliable availability across major automotive manufacturing regions, supporting just-in-time production requirements that are critical in modern automotive manufacturing.

Inventory management support helps automotive manufacturers optimize their material procurement and storage processes, with technical guidance available for proper storage conditions and shelf-life management. This comprehensive approach to packaging and logistics ensures that the Flame Retardant Heat-resistant Flannel Fabric-Single Sided Adhesive 0.3mm Thickness Black for Automotive Masking Use maintains its performance characteristics from manufacturing through final application.

Why Choose Us

Our organization brings extensive experience in developing and manufacturing specialized materials for demanding industrial applications, with particular expertise in automotive manufacturing solutions that has been recognized across international markets. This deep understanding of automotive manufacturing requirements enables us to develop products that address real-world challenges while maintaining the performance standards that professional automotive manufacturers demand. Our commitment to innovation and quality has established strong relationships with automotive manufacturers, custom tin box suppliers, and OEM tin packaging solutions providers worldwide.

Technical expertise extends beyond product manufacturing to include comprehensive application support, helping automotive manufacturers optimize their masking processes for maximum efficiency and results. Our engineering team collaborates closely with customers to understand their specific requirements and develop solutions that enhance their production capabilities. This collaborative approach has established our reputation as a reliable metal packaging supplier and partner for automotive manufacturers seeking specialized material solutions.

Global manufacturing capabilities and quality management systems ensure consistent product availability and performance standards across international markets, supporting automotive manufacturers with reliable supply chain partnerships. Our commitment to continuous improvement and customer satisfaction drives ongoing product development initiatives that anticipate future automotive manufacturing needs while addressing current challenges effectively.

Conclusion

The Flame Retardant Heat-resistant Flannel Fabric-Single Sided Adhesive 0.3mm Thickness Black for Automotive Masking Use represents a significant advancement in specialized masking materials, combining essential safety features with exceptional performance characteristics specifically engineered for automotive manufacturing applications. Its comprehensive benefits encompass flame retardancy, heat resistance, precision adhesive technology, and conformable flannel construction, making it an indispensable tool for automotive manufacturers who require reliable masking solutions under demanding conditions. The material's versatility across various automotive applications, from paint booth operations to powder coating processes, demonstrates its value as a comprehensive solution for professional masking requirements, while its commitment to quality, customization options, and reliable supply chain support establishes it as the preferred choice for automotive manufacturers seeking to enhance their production capabilities with advanced material technology.

| item | value |

| Adhesive | Acrylic |

| Use | MASKING |

| Place of Origin | China |

| Adhesive Side | Single Sided |

| Material | Flannel |

| Type | Insulation Tape |

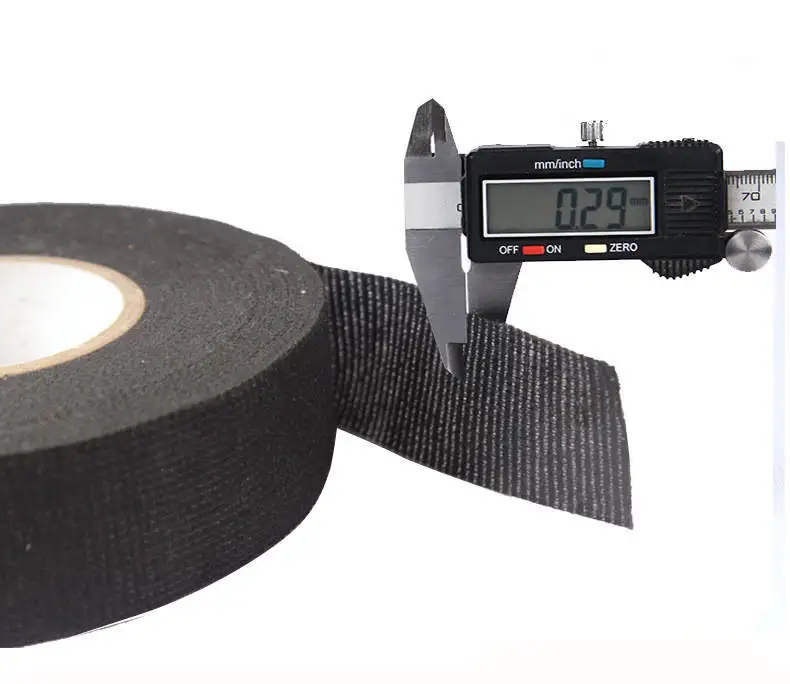

| Thickness | 0.3mm |

| Adhesive Type | Pressure Sensitive |

| Feature | Heat-resistant |

| Brand Name | YLW |

| Model Number | YLW-R001 |

| Design Printing | Offer Printing |

| cycle length | 10m |

| paper core | Customizable |

| Printing Handling | Offer printing |

| glue | Acrylic |

well

1. who are we?

We are based in Jiangsu, China, start from 2025,sell to Mid East(30.00%),Southeast Asia(20.00%),Central America(20.00%),North America(15.00%),South Asia(15.00%). There are total about - people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

automotive tape

4. why should you buy from us not from other suppliers?

-

5. what services can we provide?

Accepted Delivery Terms: -;

Accepted Payment Currency: -;

Accepted Payment Type: -;

Language Spoken: English